Intermediate support assembly of heavy vehicle drive shaft

A technology of intermediate support and transmission shaft, which is applied to vehicle parts, control devices, transportation and packaging, etc., can solve the problems that cannot be eliminated, the strength of ribs and ribs is insufficient, and the rubber production process is poor, so as to achieve good vibration-absorbing ability and good vibration-absorbing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

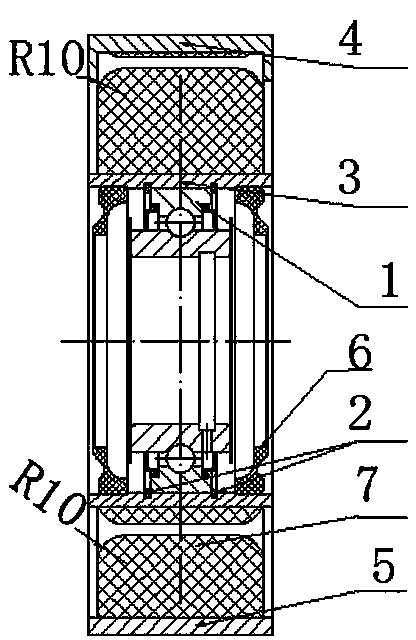

[0035] The present invention as image 3 , 4, 5, and 6.

[0036] Heavy-duty vehicle transmission shaft intermediate support assembly, including bearing 1, which is assembled in inner frame 3 through circlips 2 on both sides of bearing 1, sealing ring 6 is provided on both outer sides of bearing 1, and rubber shock absorbing pad 7 is passed outside inner frame 3 It is vulcanized as a whole with the outer cover, wherein the rubber shock absorbing pad 7 is hollowed out to form a "several"-shaped shock absorbing groove 8, and the shock absorbing groove 1 8 forms a semi-enclosed structure, so that the rubber shock absorbing pad 7 on the upper part of the inner skeleton 3 And inner skeleton 3 are all covered in " several " font gaps, and the both sides of inner skeleton 3 form gap, and rubber damping pad 7 bottoms link to each other with outer cover inner bottom and become connecting ribs.

[0037] The outer cover is divided into two parts, the lower support 5 and the upper cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com