Grounding device for high-soil resistivity region

A soil resistivity and grounding device technology, applied in the direction of connecting contact materials, etc., can solve the problems of difficulty in reducing grounding resistance, insufficient grounding area, and poor use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

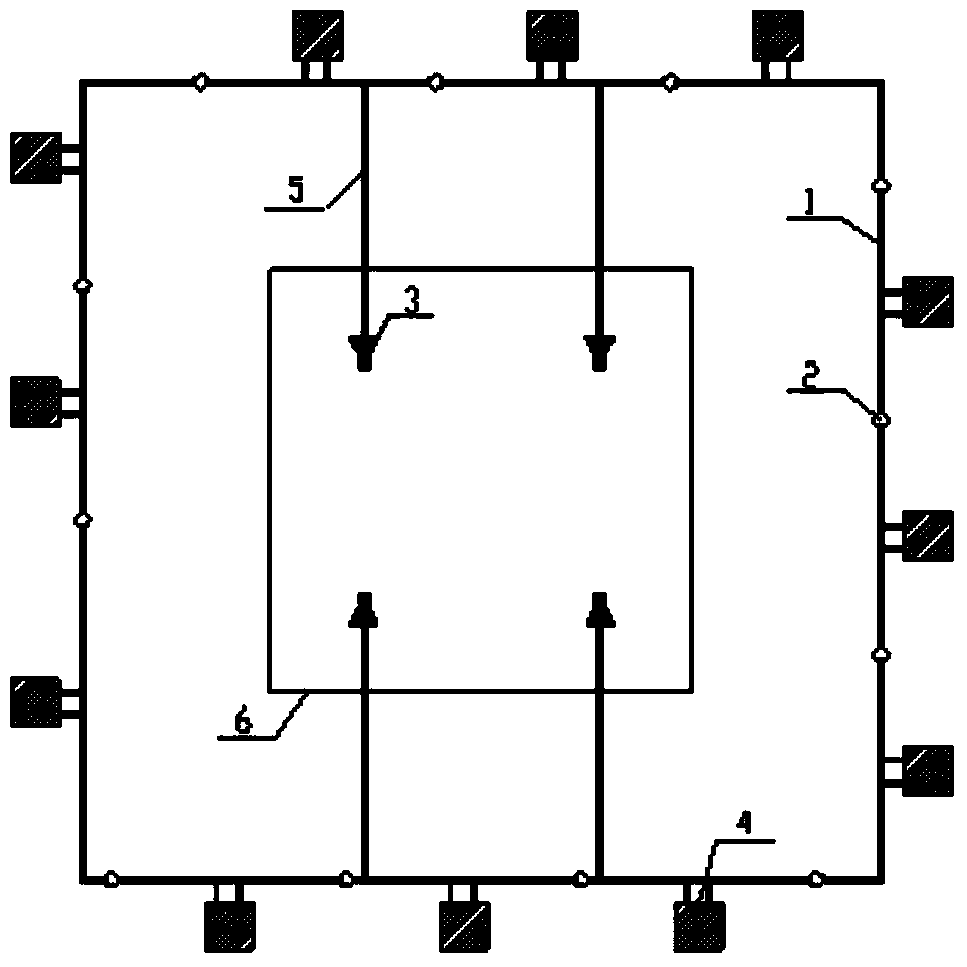

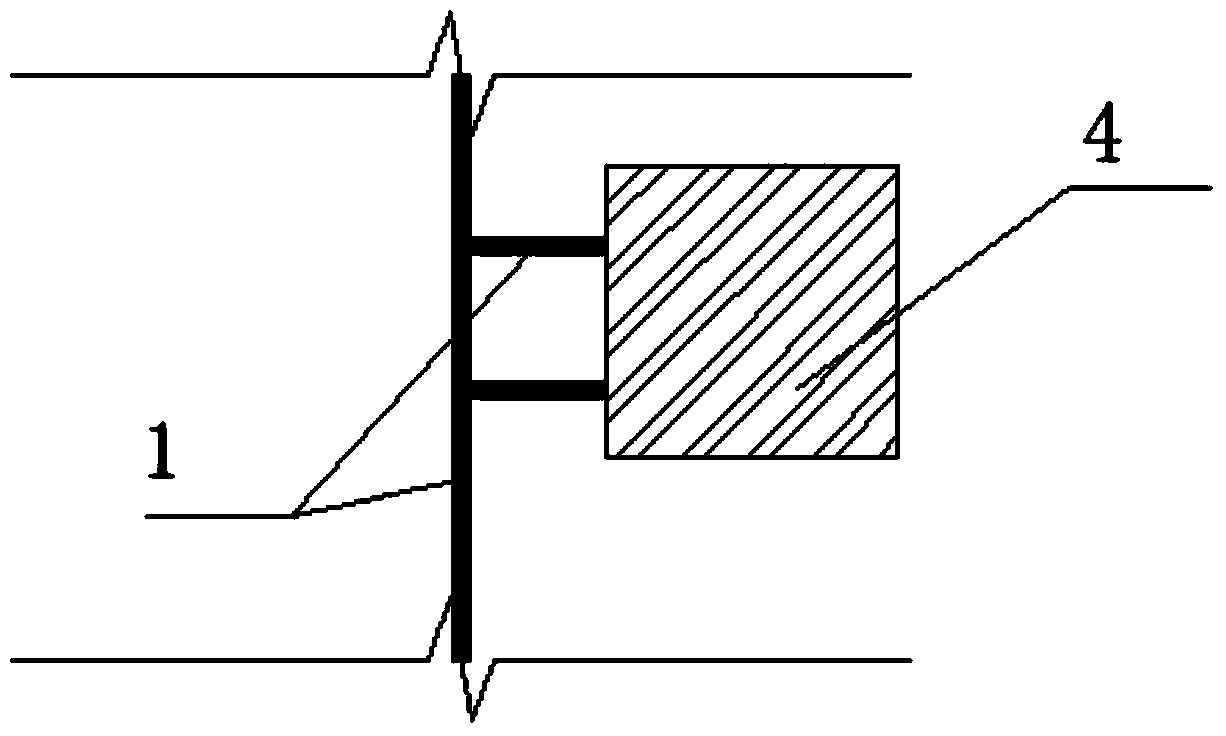

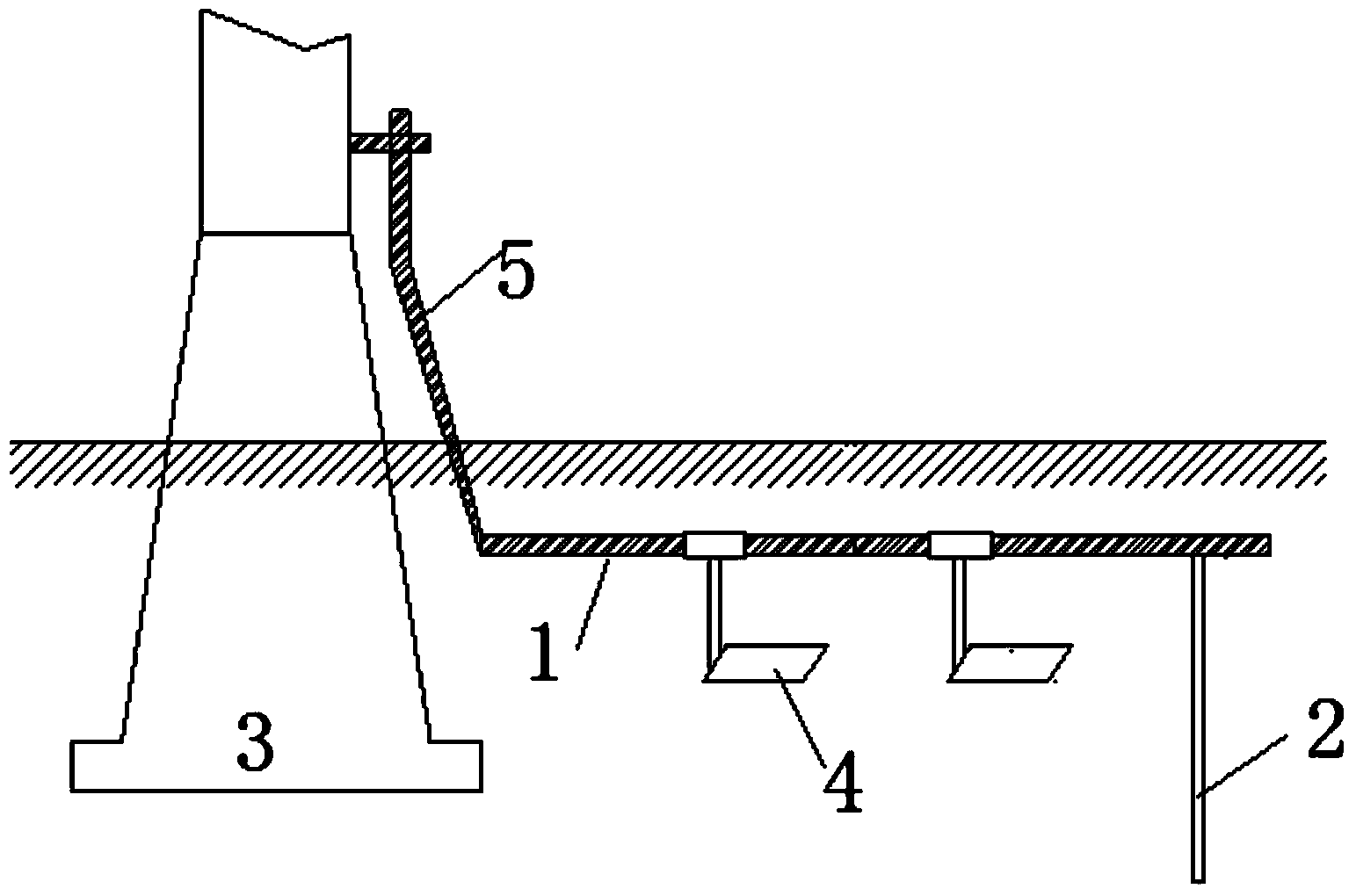

[0020] Such as Figure 1-3 As shown, the grounding device in a high soil resistivity area, the grounding device includes a plurality of grounding plates 4, each grounding plate 4 is installed on the periphery of the grounding flat steel 1, and a plurality of grounding electrodes 2 are also arranged on the grounding flat steel 1, The ground flat steel 1 is also welded to the upper part of the tower through the lightning protection down conductor 5 of the tower, and the tower is fixed on the ground through the tower foot 3;

[0021] The ground flat steel 1 has ground poles 2 as nodes, and a ground plate 4 is provided between every two adjacent nodes.

[0022] The grounding plate 4 and the grounding flat steel 1 are welded by two round steels, and the welded round steels are 20cm long connecting devices.

[0023] The ground flat steel 1 is square.

[0024] The grounding plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com