A kind of RFID electronic label with anti-transfer and no glue residue and its making method

An electronic label and anti-transfer technology, which is applied to recording carriers used in machines, instruments, computer parts, etc., and can solve the problem of poor handling of residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain and disclose the technical solution and manufacturing method of the present invention, the present invention will be described in detail below through specific examples.

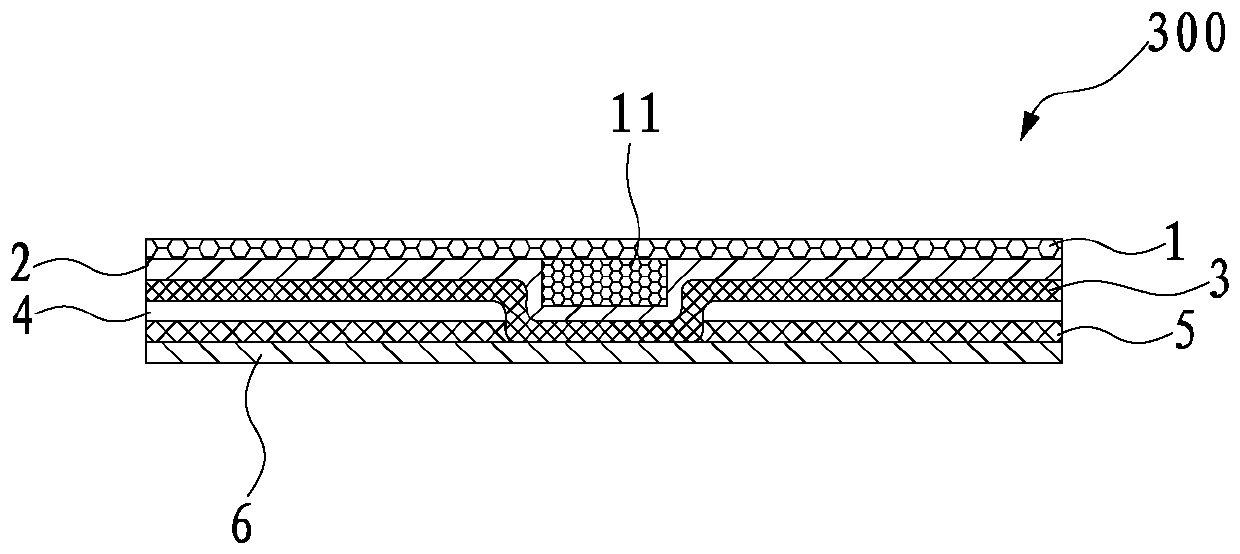

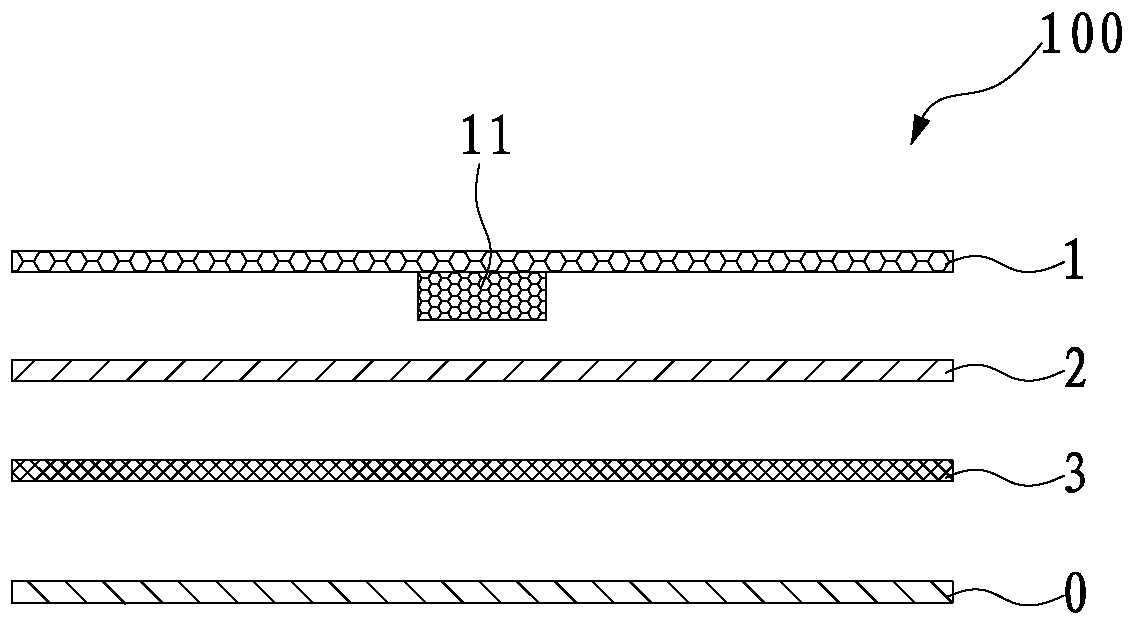

[0036] Such as figure 1 As shown, the present invention discloses an RFID electronic label 300 that is anti-transfer and has no adhesive residue, including a printing substrate with an RFID chip body 11 and a fragile film 2 sequentially compounded on the printing substrate 1 and a fragile film 2 compounded on the fragile film. The RFID fragile anti-transfer label unit 100 formed by the high-viscosity adhesive layer 3 on the film 2; the key of the present invention is:

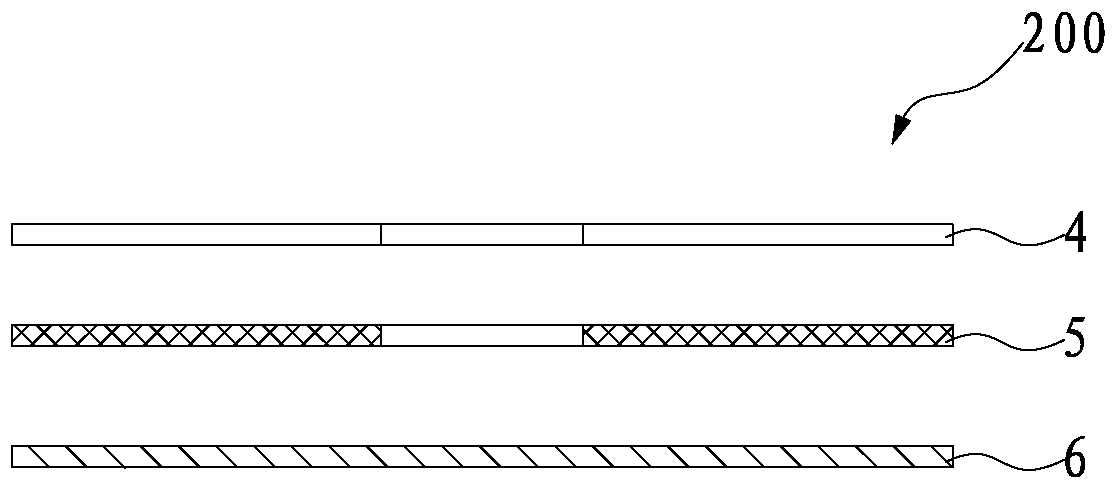

[0037] A PET transparent layer 4 is further compounded on the high-viscosity adhesive layer 3, and a low-viscosity adhesive layer 5 is compounded on the PET transparent layer 4, and the PET transparent layer 4 and the low-viscosity adhesive layer 5 correspond to the RFID fragile anti-transfer label unit 100....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com