Fatigue wear tester for rubber material

A wear test, rubber material technology, applied in the direction of testing wear resistance, etc., can solve the problems of rubber material damage, fatigue and wear can not be considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

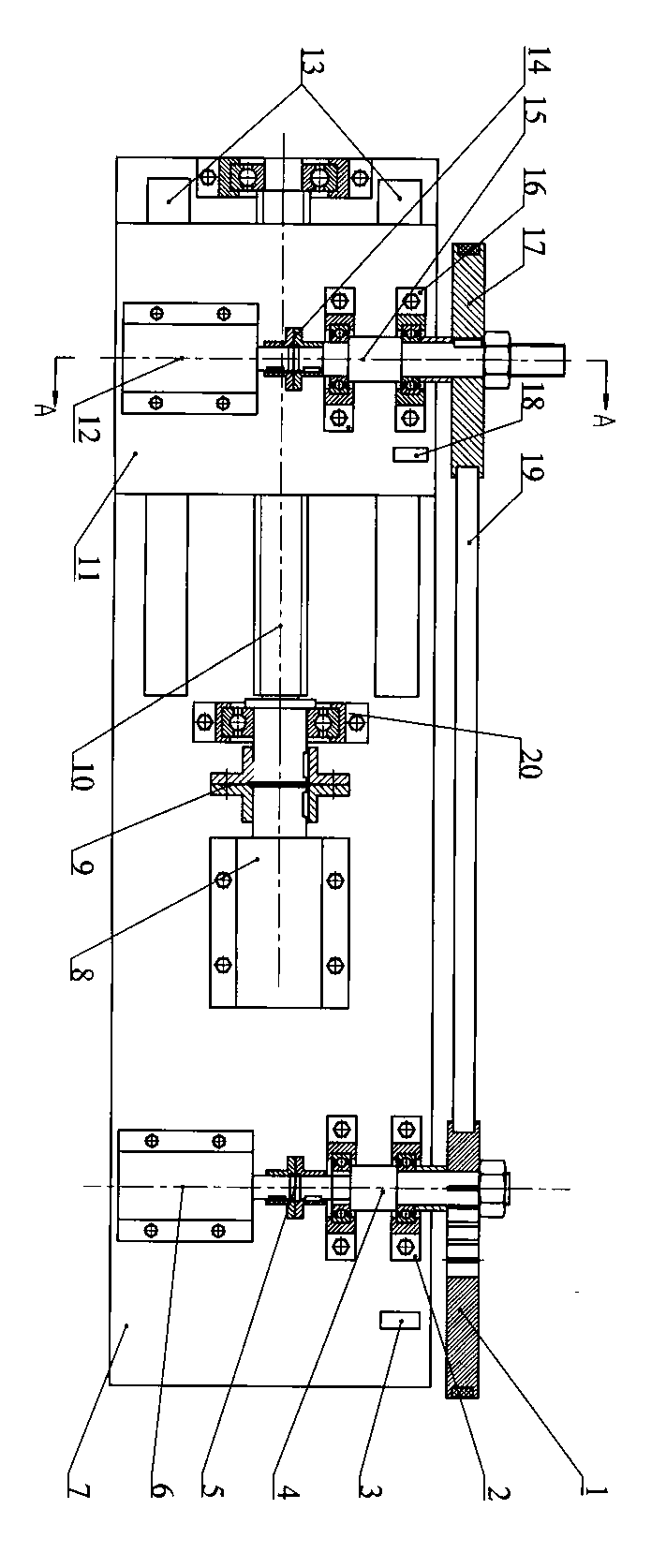

[0034] like figure 1 As shown in and 11, the adjustment wheel on the dynamic actuator is a concentric pulley 17 or a pulley 7-6; the concentric pulley 17 is fixed with the shaft 15 of the dynamic actuator through a key; as shown in Figures 5 and 6, the concentric pulley 17 and the pulley 7-6 are cylindrical cake-shaped structures, and have grooves for installing samples on the outer surface of the cylinder.

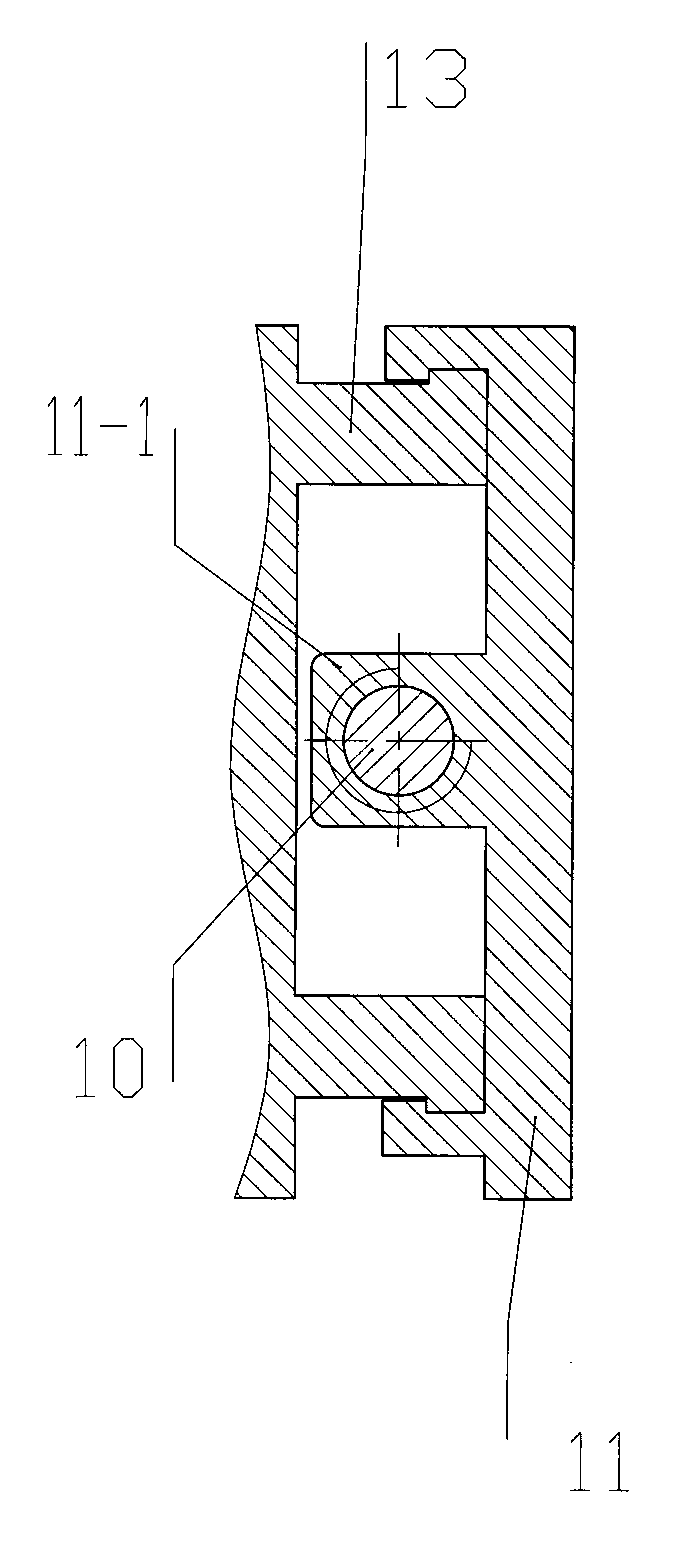

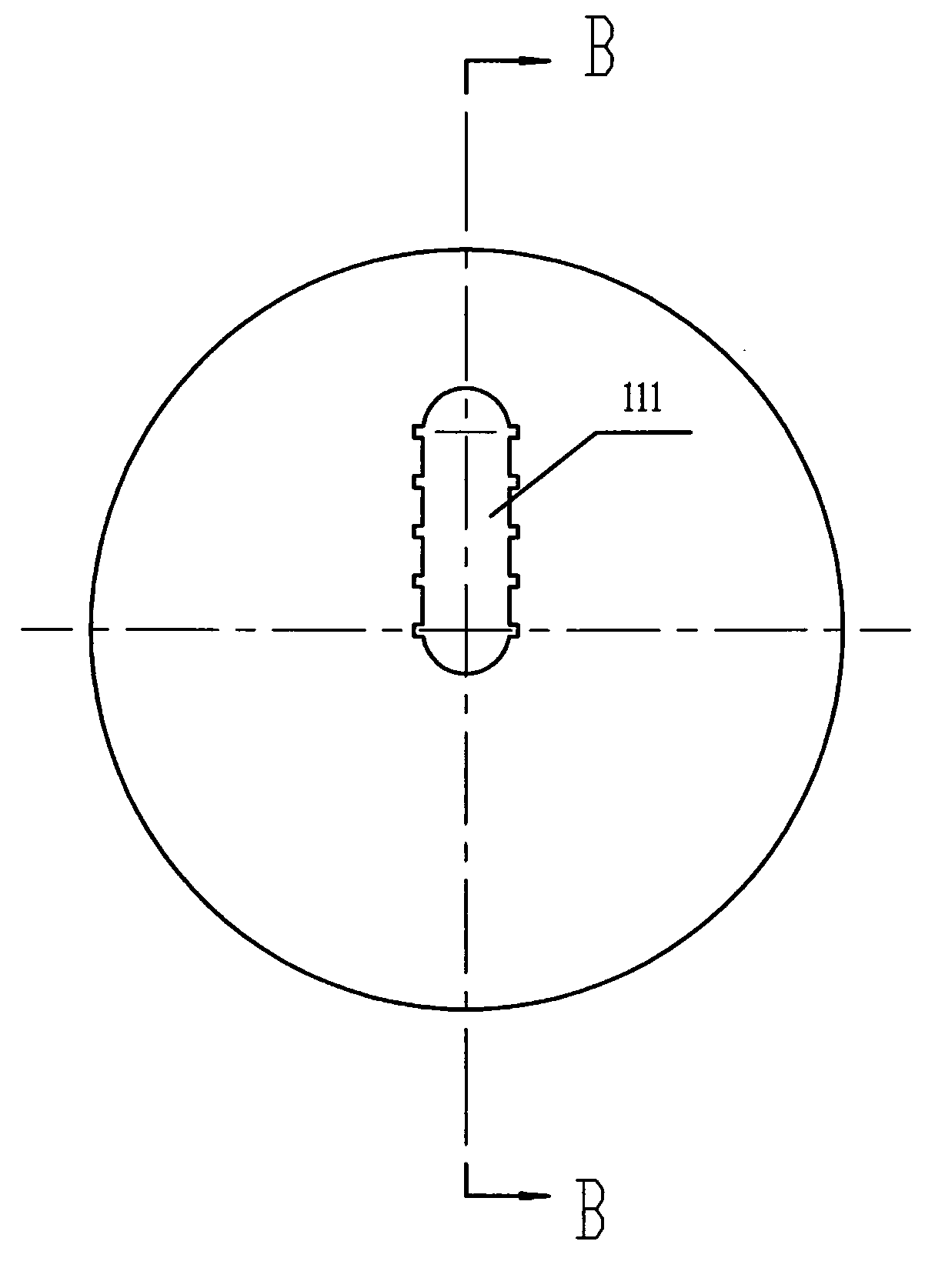

[0035] The adjustment mechanism on the fixed actuator is an adjustable pulley 1 or a composite mechanism composed of a crankshaft 7-1 and an auxiliary pulley 7-2; as shown in Figures 3 and 4, the adjustable pulley 1 is a cylindrical pie structure, There is a long hole 111 in the radial direction, the center of one end of the long hole coincides with the center of the pulley, and a symmetrical keyway is opened on the inner wall surface of the long hole 111, and the long hole 111 is set on the fixed actuator. On the shaft 4 and fixed by a key inserted in the keyway, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com