Roller-type large LED panel fixing bracket

A fixed frame and roller type technology, applied in the field of fixed frame, can solve the problems of hard damage of LED panels, difficult to put in, time-consuming and laborious, etc., and achieve the effect of stable fixed structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

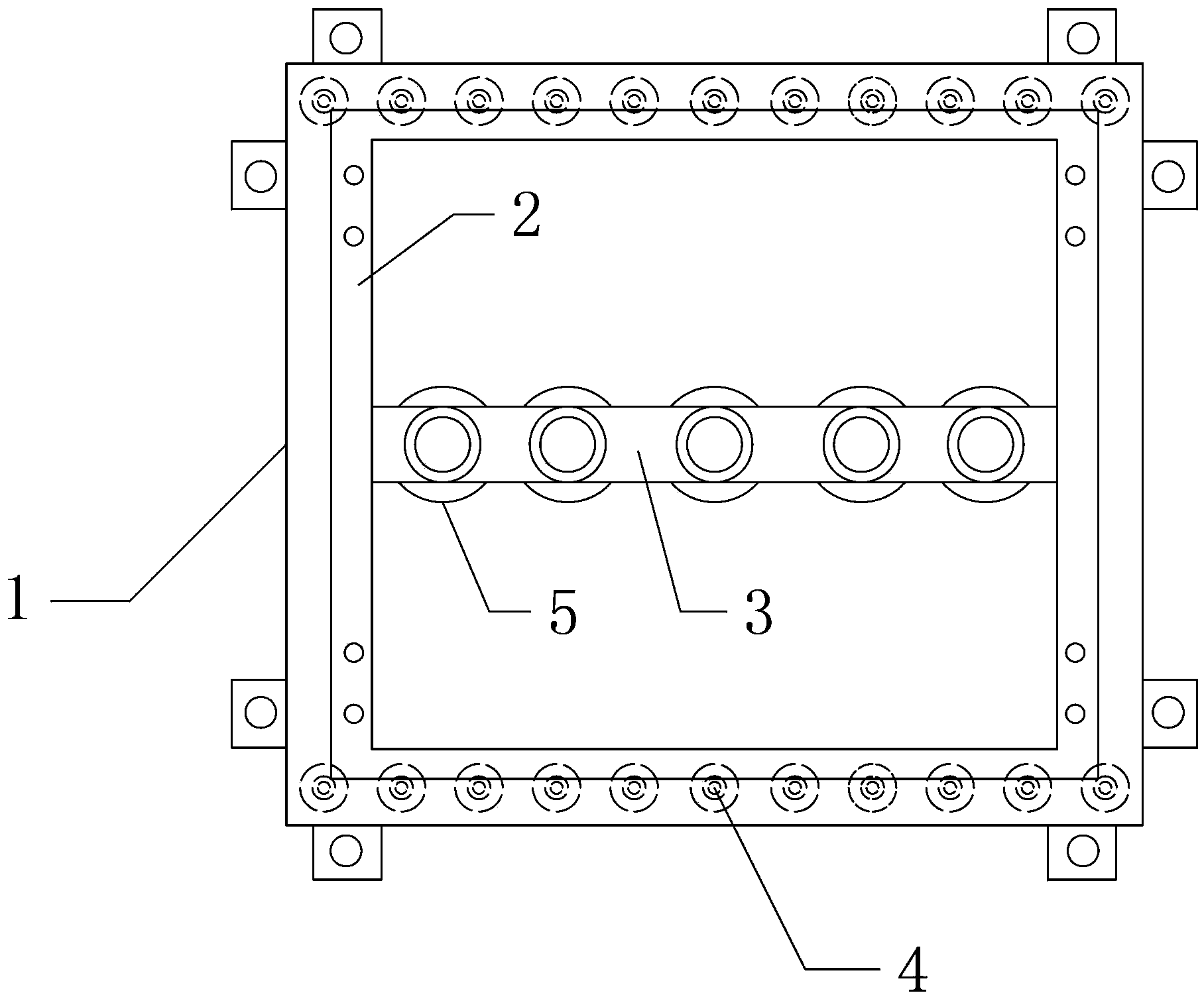

[0010] like figure 1 A roller-type large-scale LED panel fixing frame shown includes: a fixing frame 1 and a pressure plate 2 having the same shape as the fixing frame 1; at least one side of the fixing frame 1 frame is connected to the fixing frame 1 by a detachable fixed connection, through This structure realizes the side insertion of the LED panel;

[0011] There is not at least one beam 3 fixed in the fixed frame 1; a small roller 4 is fixed on the inner wall of the fixed frame 1; a large roller 5 is fixed on the beam 3, through this structure, the small LED panel can be smoothly inserted on the side after splitting. stitching;

[0012] The small roller 4 and the big roller 5 use rollers with soft rubber material on the surface, which is to protect the safety and stability of the LED panel during insertion and splicing;

[0013] The final fixing of the pressing plate 2 to the fixing frame 1 realizes the overall fixing of the spliced LED panel.

[0014] The above desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com