Shaft holder

A gripper and shaft clamp technology, applied in the direction of friction clamping detachable fasteners, connecting components, mechanical equipment, etc., can solve the problems of narrow application range, inability to achieve clamping and locking, etc. Large, good centering effect, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

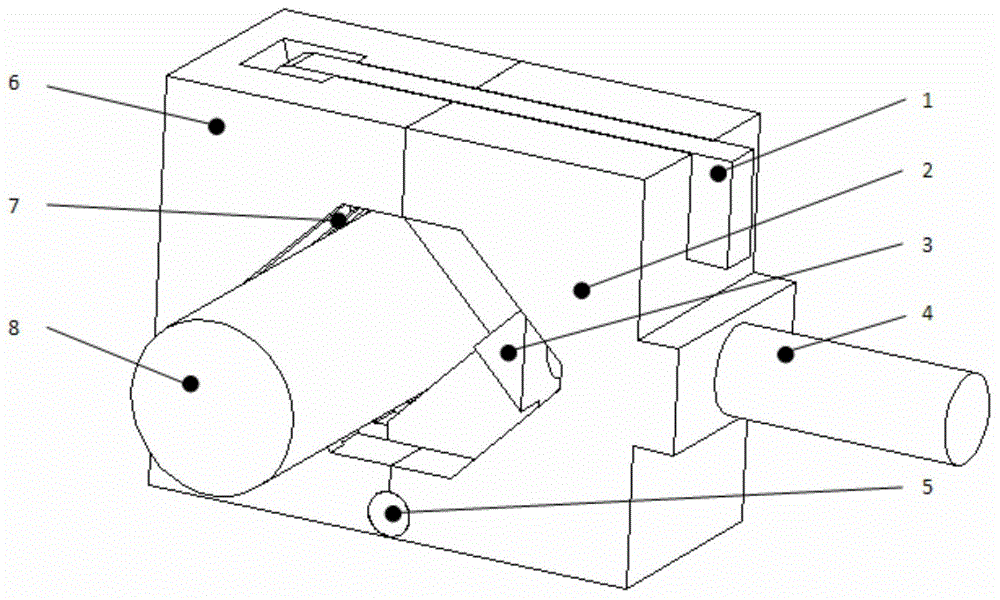

[0043] Such as figure 1 As shown, a shaft holder includes a V-shaped block, a housing and a V-shaped block compression screw 4; the V-shaped block includes a left fixed V-shaped block 7 and a right movable V-shaped block 3, and the housing It includes a left housing 6 and a right housing 2; the shaft holder also includes a left and right housing locking buckle 1; the left fixed V-shaped block 7 and the right movable V-shaped block 3 are respectively wrapped by the housing; the The left fixed V-shaped block 7 is fixedly connected with the housing; the left fixed V-shaped block 7 and the right movable V-shaped block 3 are provided with cross-arranged meshing teeth on the opposite teeth, so that the two can adapt to different The diameter range of the clamped object changes; the top of the housing is provided with a guide groove, and the right movable V-shaped block 3 is higher than the left fixed V-shaped block 7, and its higher part is embedded in the guide groove on the top of...

Embodiment 2

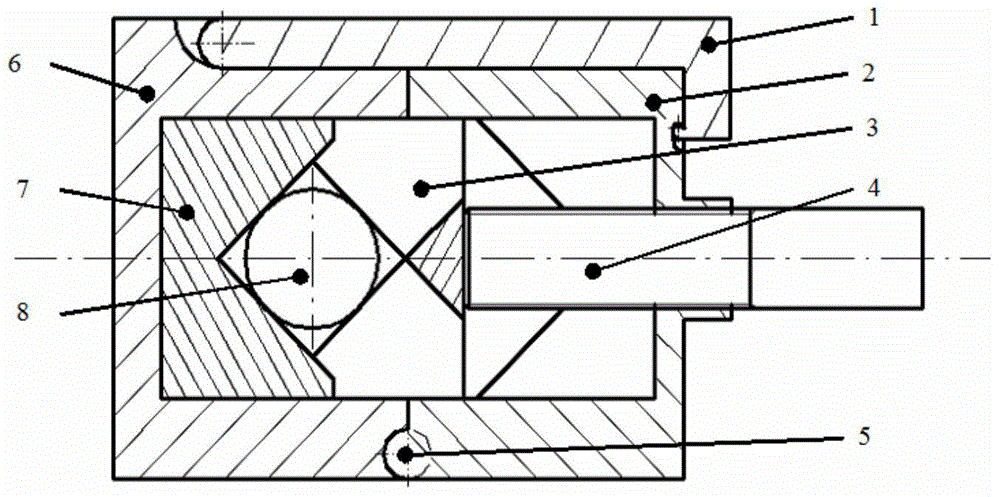

[0045] Such as figure 2 As shown, a shaft holder is similar to Embodiment 1, the difference is that the diameter of the clamped part 8 is determined by both the shell and the V-shaped block, when the V-shaped block compresses the screw 4 When moving to the rightmost end, the distance between the left fixed V-shaped block 7 and the right movable V-shaped block 3 is the largest, and the diameter of the clamped part 8 is the largest without touching the housing; when the V-shaped block compresses the screw 4 When pushed to the far left, the left fixed V-shaped block 7 and the right movable V-shaped block 3 are engaged with each other, and if the volume permits, the two can be completely engaged until the gap between them is zero; the V-shaped block presses the screw rod 4 is connected with the right housing 2 through a fine thread, and is in movable contact with the right movable V-shaped block 3 .

Embodiment 3

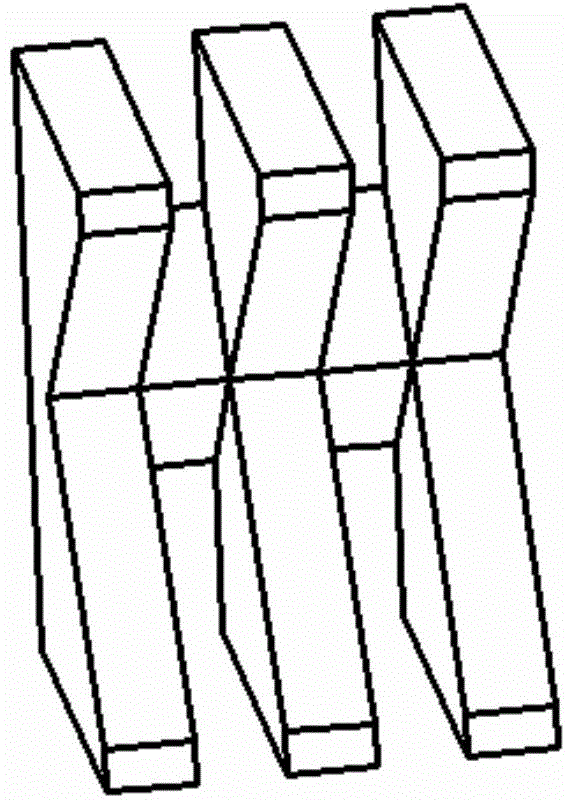

[0047] Such as Figure 3 to Figure 5 As shown, a shaft holder is similar to Embodiment 2, the difference is that the upper, lower and rear sides of the left fixed V-shaped block 7 are in contact with the inside of the left housing 6, and it passes through the two middle parts. A countersunk head bolt is fixed on the left housing 6, and the bolt only plays a positioning role, and does not bear compressive force or tensile stress during the clamping process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com