A kind of preparation method and application of micron tubular silver simple substance

An elemental, tubular technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low efficiency of organic pollutants, and achieve the preparation method Simple, speed up oxidative decomposition rate, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The following tests were carried out at a room temperature of 10-12°C.

[0023] Weigh 0.05g (0.00078mol) of copper powder into a small beaker, add 30mL of deionized water, then add 0.8g (0.0070mol) of PVPK-30 (Sinopharm Chemical Reagent Co., Ltd., the same below) and stir for 10 minutes to make The system is uniformly dispersed, and solution A is obtained. Weigh 0.318g of AgNO 3 (0.00187mol) into another beaker, add 10mL deionized water to dissolve, and obtain silver nitrate solution. Under the stirring state, the silver nitrate solution is poured into the solution A at one time, and the reaction is carried out under the stirring state until the color of the reaction system changes from red to black, and the reaction is completed to obtain a reaction mixture solution. Add 2.1014g (0.01mol) of citric acid monohydrate to the reaction mixture solution, stir for 10 minutes to make the system uniform, centrifuge to collect the precipitate, wash with water and ethanol in se...

Embodiment 2

[0025] The following tests were carried out at a room temperature of 15-18°C.

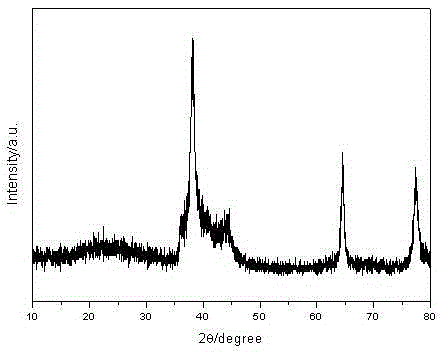

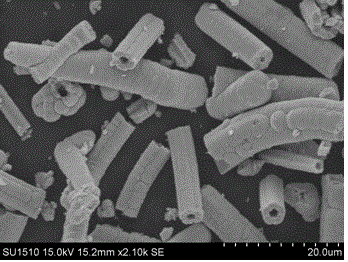

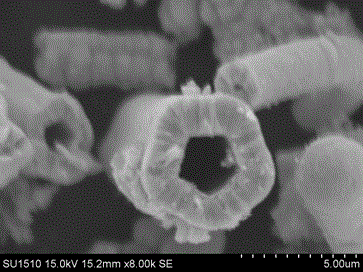

[0026] Weigh 0.05g (0.00078mol) of copper powder into a small beaker, add 30mL of deionized water, then add 3.5g (0.0315mol) of PVPK-30 into the beaker, stir for 10 minutes to disperse the system evenly, and obtain solution A. Weigh 3.312g (0.0195mol) of AgNO 3 In another beaker, add 10mL deionized water to dissolve to obtain a solution containing silver ions. Under stirring, the AgNO 3 The solution was poured into the solution A at one time, and the reaction was carried out under stirring until the color of the reaction system changed from red to black to obtain a reaction mixture solution. Add 4.2028g (0.02mol) of citric acid monohydrate to the reaction mixture solution, stir for 20 minutes to make the system uniform, centrifuge to collect the precipitate, wash with water and ethanol in turn, and dry at 60°C for 6 hours to obtain material 2. From the X-ray electron diffraction image of materia...

Embodiment 3

[0028] The following tests were carried out at a room temperature of 26-28°C.

[0029] Weigh 0.05g (0.00078mol) of copper powder into a small beaker, add 30mL of deionized water, then add 5.3g (0.0477mol) of PVPK-30 into the beaker, stir for 10 minutes to disperse the system evenly, and obtain solution A. Weigh 6.625g (0.0389mol) of AgNO 3 In another beaker, add 10mL deionized water to dissolve to obtain a solution containing silver ions. Under stirring, the AgNO 3 The solution was poured into the solution A at one time, and the reaction was carried out under stirring until the color of the reaction system changed from red to black to obtain a reaction mixture solution. Add 6.3042 g (0.03 mol) of citric acid monohydrate to the reaction mixture solution, stir for 30 minutes to make the system uniform, centrifuge to collect the precipitate, wash with water and ethanol in sequence, and dry at 65°C for 5 hours to obtain material 3. From the X-ray electron diffraction image of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com