T-shaped structure connector for photovoltaic inverter

A technology of photovoltaic inverters and connectors, which is applied in the direction of connection, parts of connection devices, contact parts, etc., can solve the problem that the cumbersomeness of operation has not been significantly improved, the processing efficiency has not been improved, and the connector assembly efficiency has decreased and other issues, to achieve the effects of mass production, space saving, and simplification of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

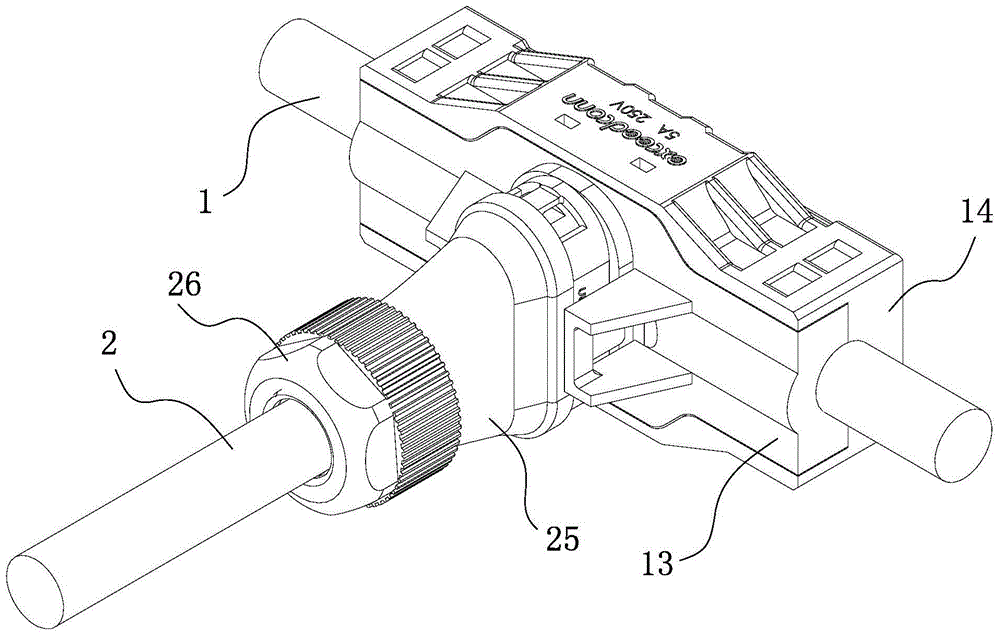

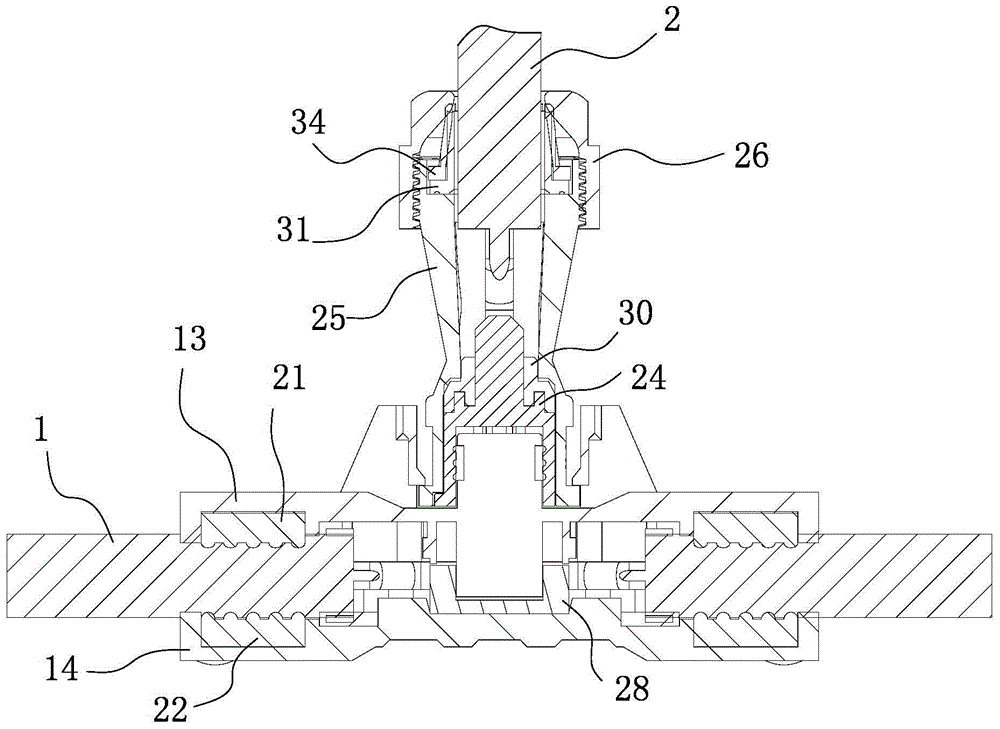

[0031] Embodiment one: see Figure 2-9 As shown, a T-shaped structure connector of a photovoltaic inverter includes a male end and a female end. The male end is installed on the bus 1, and four core wires 3 are drawn out through the male terminal, corresponding to each core wire 3 is provided with a socket 11 at the male end, the female end is connected to the branch line 2, and the core wires of each female end are drawn out through the female terminal 12, and corresponding to the female end of each core wire is provided with the socket A plug with a matching hole, the male end and the female end are plugged together to form a T-shaped structural connector, such as figure 2 shown.

[0032] like Figure 4As shown, the male end is provided with a shell outside, and the shell is composed of an upper cover 13 and a lower cover 14. Protrusions 15 are respectively provided on the outer walls on both sides of the middle part of the upper cover 13. On the lower cover 14, There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com