High-pressure spraying based environmental management system

A spray system and environmental treatment technology, applied in spraying devices, comprehensive factory control, comprehensive factory control, etc., can solve the problems of low dust removal power, adjustment of dust removal power, difficult automatic control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

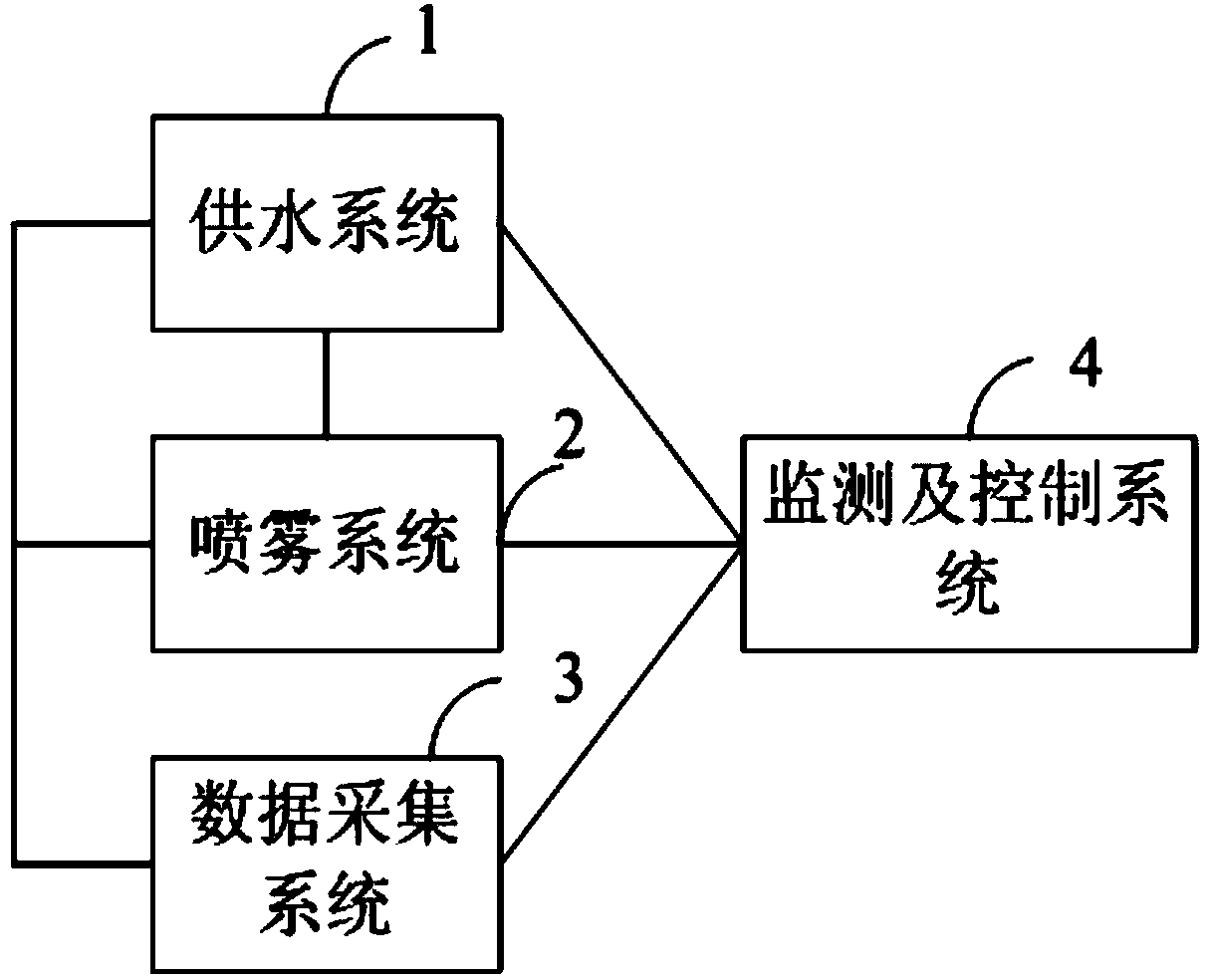

[0033] see figure 1 A structural schematic diagram of an embodiment of an environment treatment system based on high-pressure spraying of the present invention is shown. Depend on figure 1 It can be seen that, in this embodiment, the system includes: a water supply system 1, a spray system 2 connected to the water supply system 1, a data acquisition system 3, and a water supply system, the spray system 2 and the data acquisition system respectively. monitoring and control system4.

[0034] Among them, the data acquisition system 3 is used to collect various parameters of the surrounding environment, such as parameters such as temperature, humidity, and particle content, as well as to collect the water pressure of each device in the water supply system 1 and the spray system in the system, and then collect the collected parameters. The parameters are sent to the monitoring and control system 4, so as to monitor and control the spraying process of the spraying system 2 by the ...

Embodiment ( 2

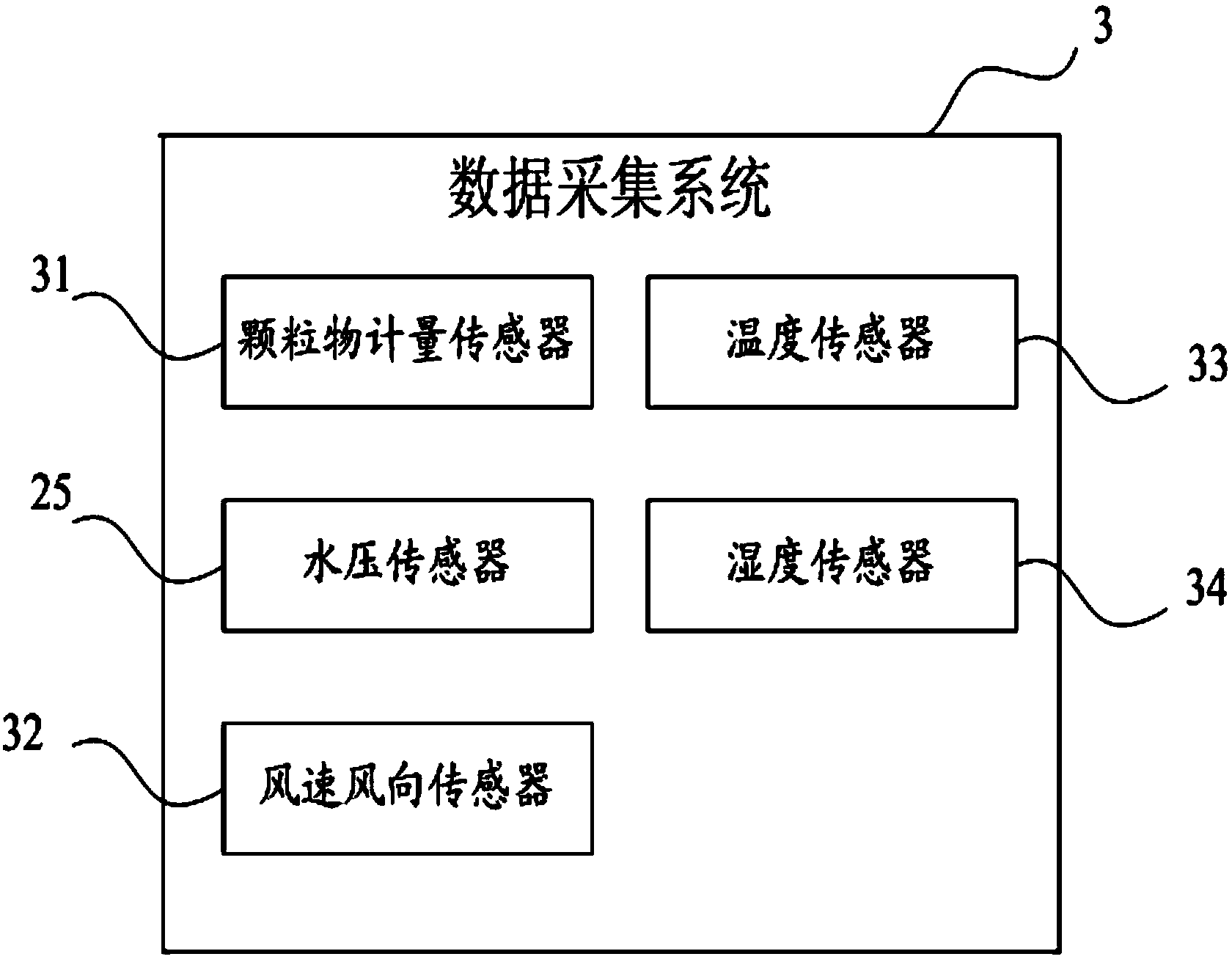

[0042] see figure 2 It shows a structural schematic diagram of another embodiment of the high-pressure spray-based environmental treatment system of the present invention.

[0043] Different from Embodiment (1), in this embodiment, the data acquisition system 3 specifically includes:

[0044] A particle metering sensor 31 for detecting the particle content in the surrounding environment;

[0045] A wind speed and direction sensor 32 for detecting wind speed and wind direction;

[0046] A temperature sensor 33 for detecting ambient temperature;

[0047] A humidity sensor 34 for detecting ambient humidity;

[0048] And the water pressure sensor 35 that detects the water pressure in the water supply system and spraying system.

[0049] The data acquisition system 3 detects the surrounding environment through various sensors, so as to control the state of the surrounding environment from various aspects.

Embodiment ( 3

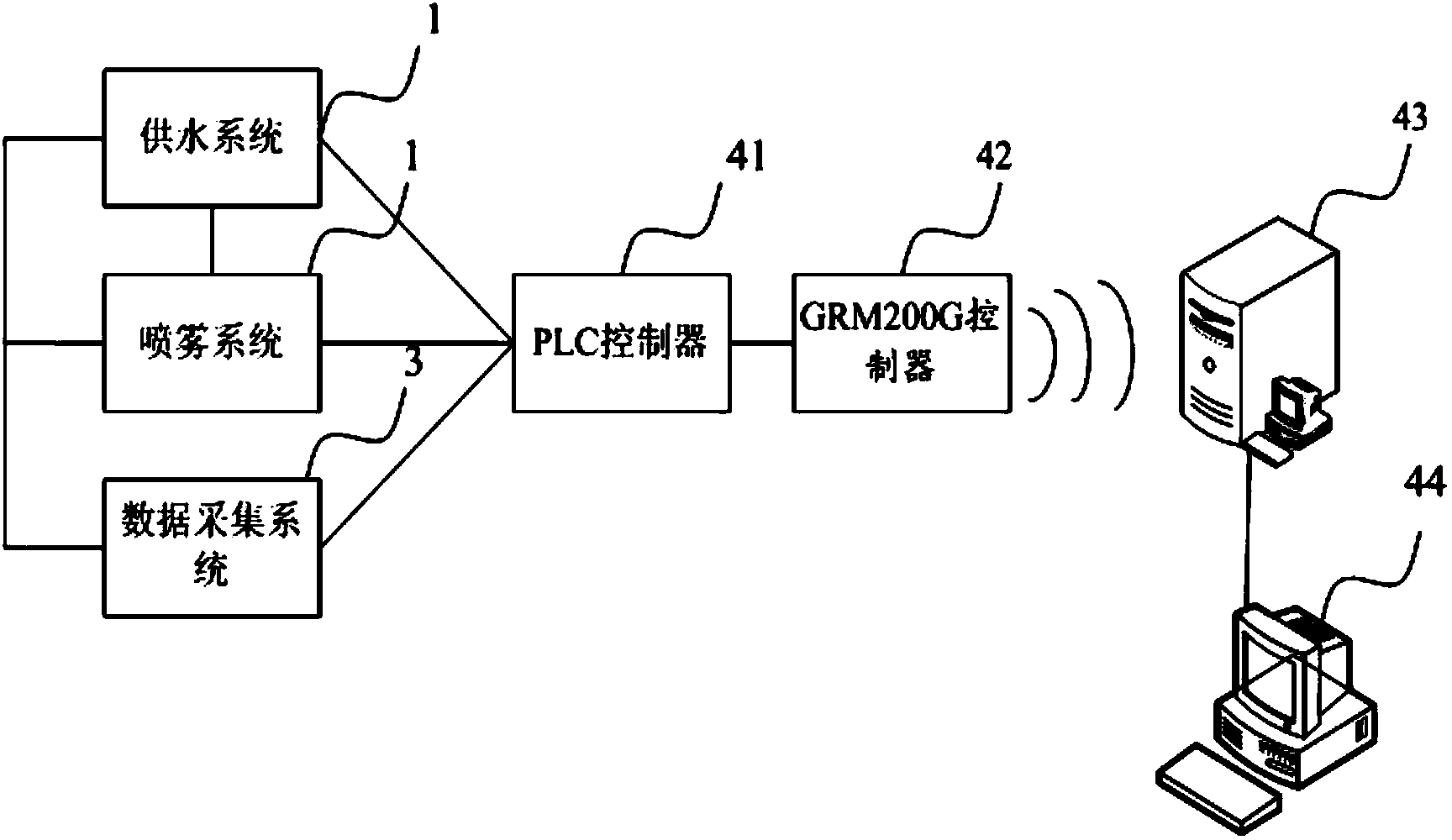

[0051] see image 3 It shows a structural schematic diagram of another embodiment of the high-pressure spray-based environmental treatment system of the present invention.

[0052] In this embodiment, the system includes: a water supply system 1 , a spray system 2 connected to the water supply system 1 , a data acquisition system 3 and a monitoring and control system 4 .

[0053] Wherein, the monitoring and control system 4 includes: a PLC controller 41 that outputs control instructions to the spray system 2, a GRM200G controller 42 connected to the PLC controller 41, a cloud monitoring server 43, and a remote monitoring terminal 44;

[0054] Wherein, the GRM200 controller 42 is connected to the PLC controller 41 through RS485 to read the running state of the PLC controller 41, and send the read state data to the cloud monitoring through a wireless network, such as a GPRS network Server 43.

[0055] The remote monitoring terminal 44 can obtain the status data of the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com