Leakage detecting head, condenser on-line leakage detecting device and applications thereof

A detection head and condenser technology, applied in the field of leak detection detection head, can solve the problems of low efficiency, low detection efficiency, cumbersome operation, etc., and achieve the effects of reducing maintenance costs, prolonging operating hours, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

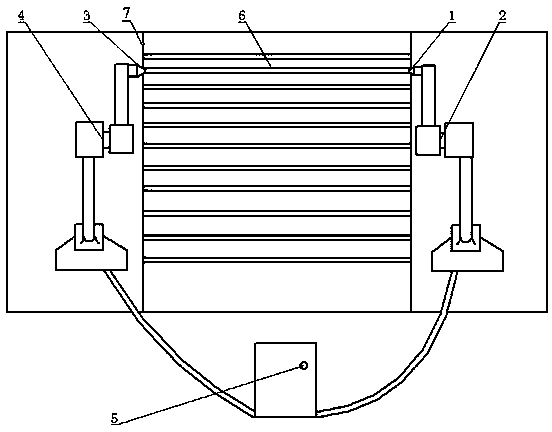

[0039] Such as Figure 4As shown, the online condenser leak detection device of the present invention includes: a leak detection probe 1 , a first mechanical arm 2 , a plugging device 3 , a second mechanical arm 4 and a control system 5 . Among them, the mechanical arm 1 2 and the mechanical arm 2 4 are respectively installed in the two water chambers of the condenser, and the dual-degree-of-freedom mechanical arms can move along the area parallel to the tube sheet 7 plane of the condenser. The leak detection probe 1 and the plugging device 3 are installed on the first mechanical arm 2 and the second mechanical arm 4 respectively. The control system 5 adopts a PLC control system or a DCS of a power plant, and connects the first mechanical arm 2, the second mechanical arm 4, the leak detection probe 1 and the plugging device 3 through control lines.

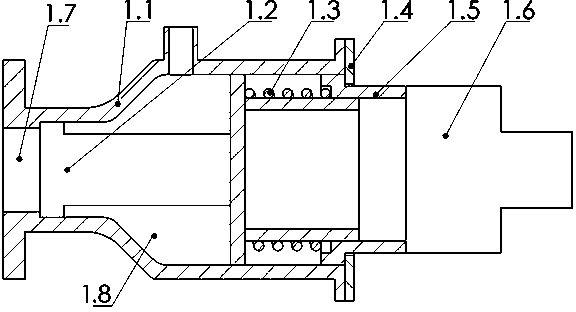

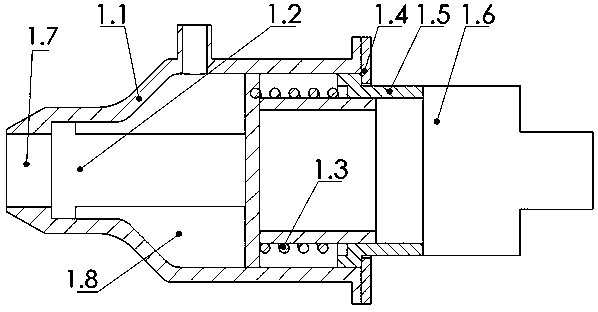

[0040] The lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com