Small and medium throwing machine

A throwing machine, small and medium-sized technology, used in throwing machines, transportation and packaging, etc., can solve the problems of no material limiting device, manual manual adjustment, inability to adapt to the throwing machine, etc., to achieve uniform raw materials, prevent clogging and damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

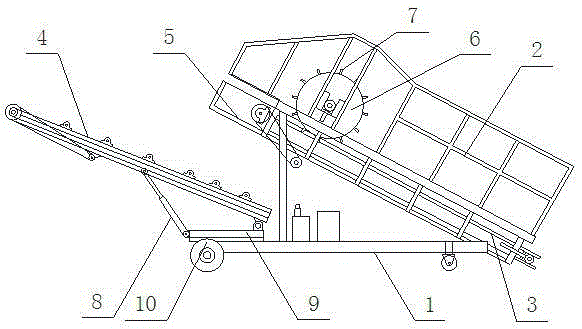

[0012] Example: see figure 1 , a small and medium-sized throwing machine, including a body 2 and a base 1 for placing the body 2, one end of the body 2 is arranged obliquely upward, and the body 2 is provided with a conveyor chain 3 for conveying obliquely upward, and the throwing machine also includes a Also be arranged on the conveyor belt 4 on the base 1, and the conveyor belt 4 is arranged at the lower end of the discharge port 5 of the body 2; a higher end of the body 2 is provided with a material limiting drum 6, which is located at the feeding The upper end of the chain 3, and its axial direction is perpendicular to the moving direction of the conveying chain 3.

[0013] Preferably, the outer cylindrical surface of the material limiting drum 6 is tangent to the conveying chain, and several dispersion blocks 7 are arranged on it, and the dispersion blocks 7 are evenly distributed on the outer cylindrical surface of the material limiting drum 6 .

[0014] As a preference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com