Coreless disc type motor

A disc motor, ironless technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low production efficiency, poor maintainability, large stator magnetic field air gap, etc., and achieve simple and convenient maintenance and maintenance. Convenience and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

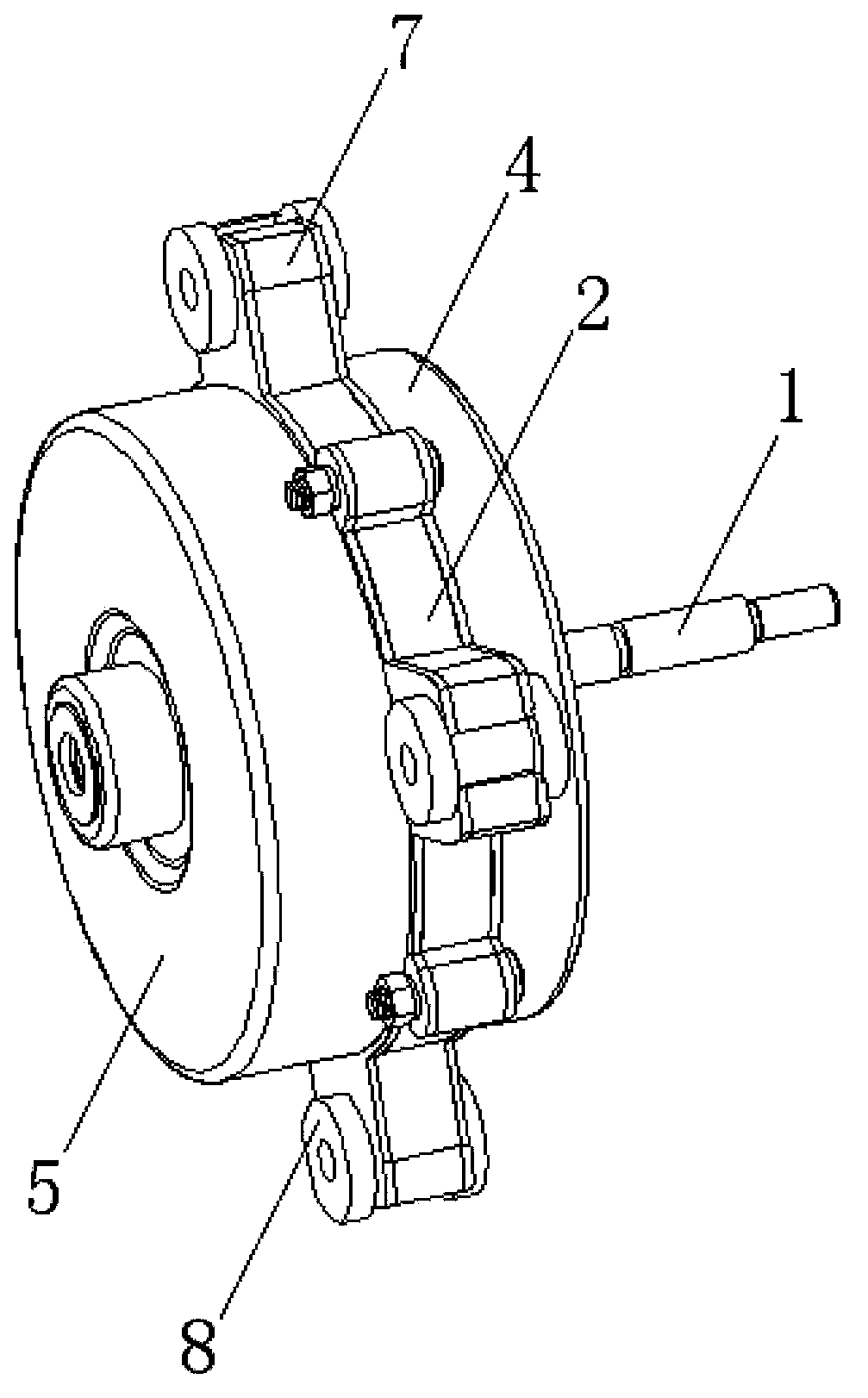

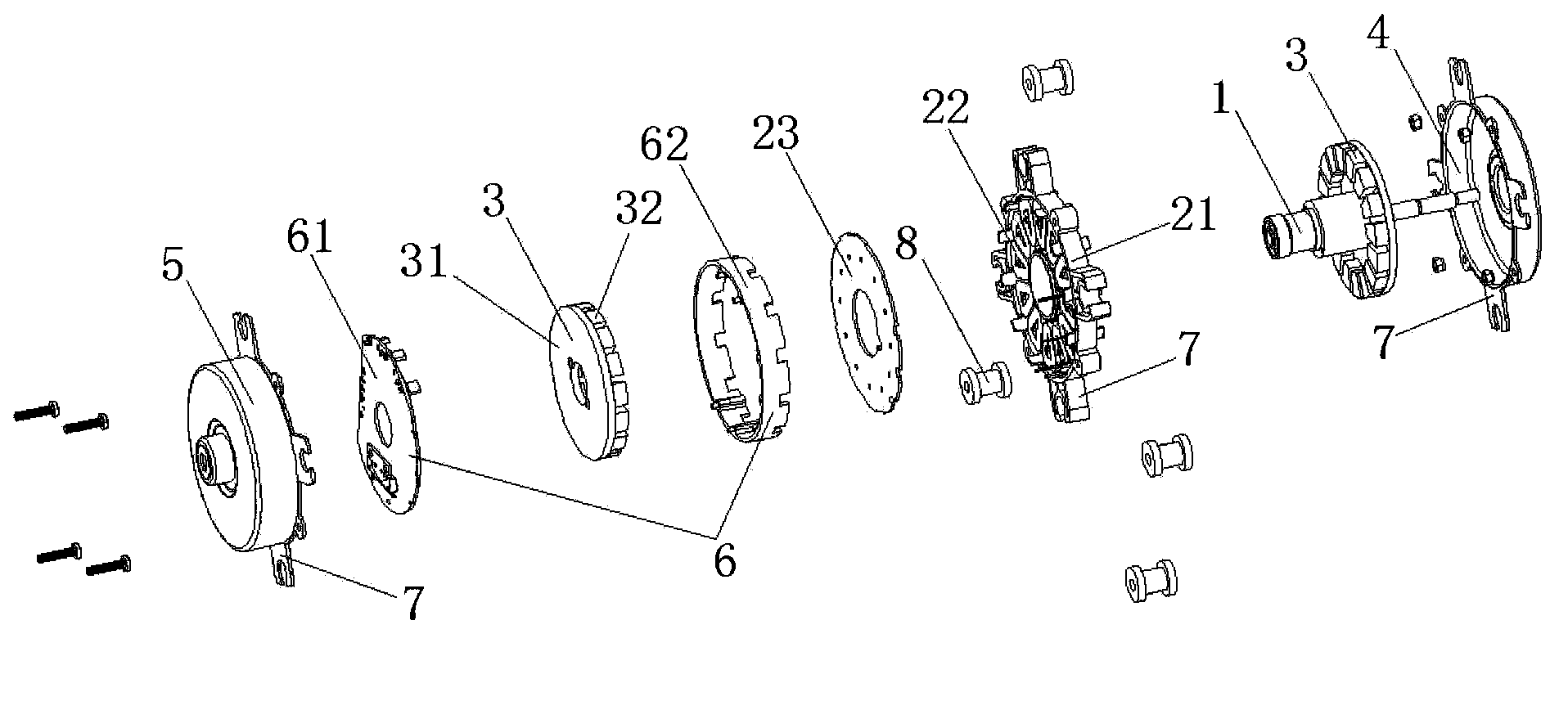

[0036] See figure 1 The coreless disc motor of this embodiment includes a shaft 1, a disc-shaped stator assembly 2 sleeved in the middle of the shaft 1, a disc-shaped rotor assembly 3 arranged on both sides of the stator assembly 2 and fixedly connected to the shaft 1, The front end cover 4 and the rear end cover 5 fixed on both sides of the stator assembly 2, the circuit board assembly 6 fixed on the stator assembly 2, a plurality of positioning claws 7, and a shock absorber 8 installed in each positioning claw 7 .

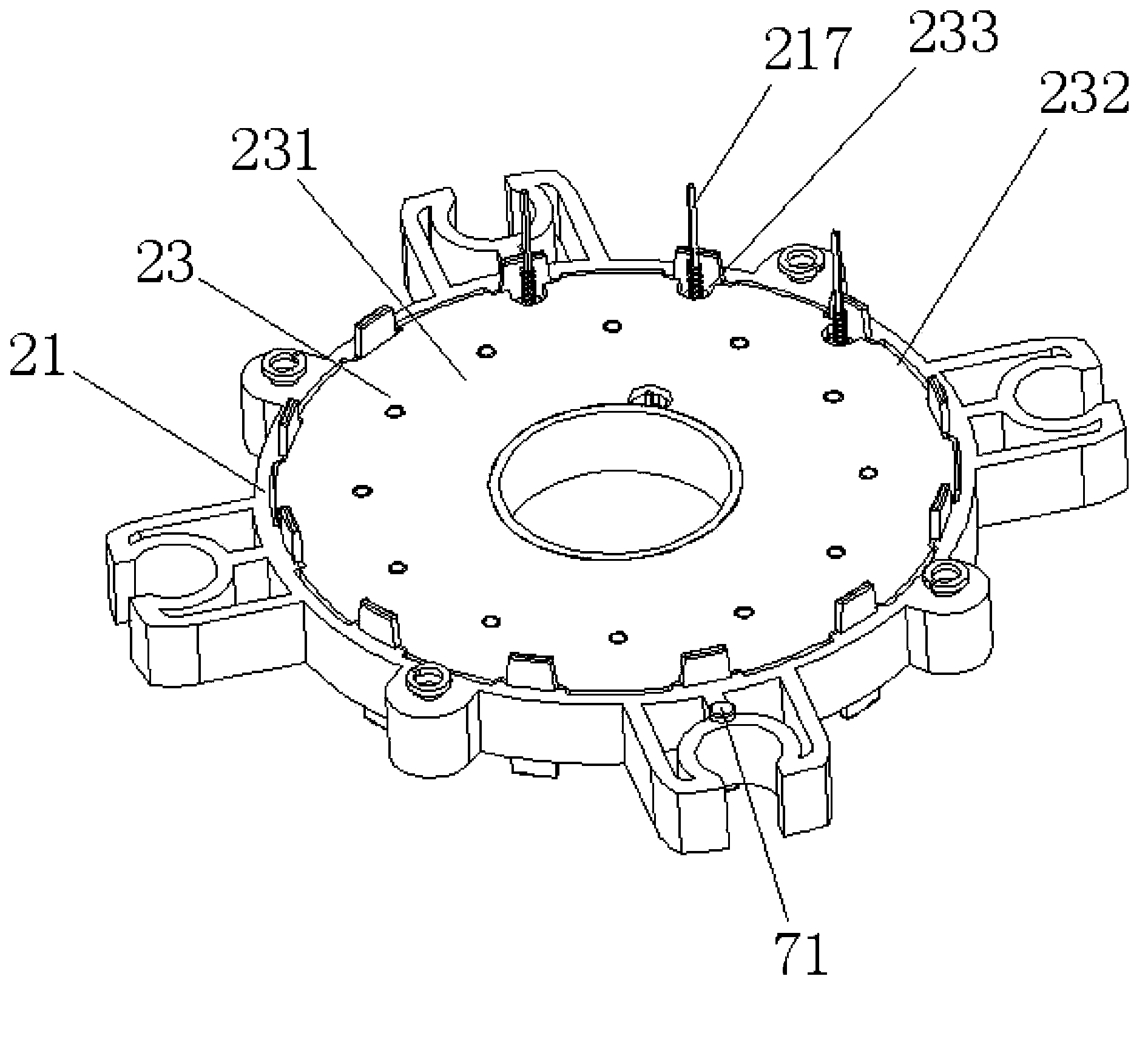

[0037] The stator assembly 2 includes a coil fixing bracket 21 , a coil assembly 22 and a coil cover plate 23 . The coil fixing bracket 21 is disc-shaped, and its central hole 212 is sleeved in the middle of the shaft 1 . The front end cover 4 and the rear end cover 5 are respectively fixed on both sides of the coil fixing bracket 21 . A plurality of fan-shaped coil positioning blocks 211 are arranged in the coil fixing bracket 21 . The coil assembly 22 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com