End terminal on-load voltage regulation single-phase 220 kV high-impedance transformer

A high-impedance transformer and voltage regulation technology, applied in the field of transformers, can solve problems such as rising manufacturing costs, elimination of enterprises, and inability to fully satisfy power users, and achieve the effects of controllable oscillation potential, reasonable structure, and superior performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

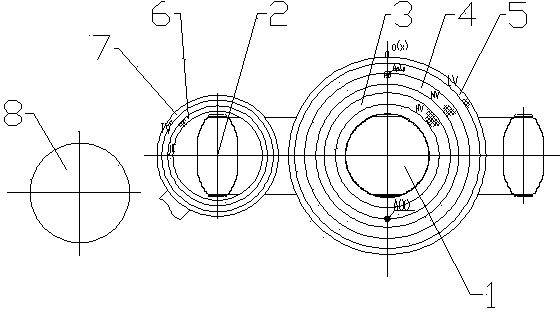

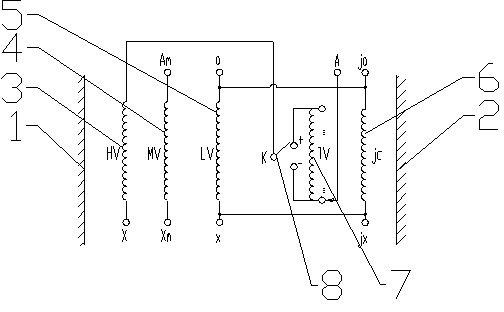

[0014] Accompanying drawing is the specific embodiment of the present invention. Such as figure 1 , figure 2 As shown, this type of line-end on-load voltage regulation single-phase 220kV high-impedance transformer, the core structure of this type of transformer adopts a single-phase three-column structure, and its core columns are divided into one core main column 1 and two iron core side columns 2 , where the cross-sectional area of the core side column 2 is 50% to 56% of the cross-sectional area of the core main column 1. The specific value can be determined according to parameters such as no-load loss, no-load current, and noise. Two core side columns are 2 points On both sides of the main column 1 of the iron core, the main column 1 of the iron core is sequentially sleeved with a high-voltage winding 3, a medium-voltage winding 4 and a low-voltage winding 5, and one of the side columns 2 of the iron core is sequentially sleeved with an excitation winding 6 and Volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com