Airtight leak-prevention method for sealing gaps between wellhead packing box and polished rod

A packing box, air-tight technology, used in sealing/isolation, earthwork drilling, wellbore/well components, etc., can solve the problem of increasing the hanging point load of the pumping unit, unsatisfactory sealing effect, and increasing the friction of polished rods. It can reduce the load, solve the oil leakage and reduce the friction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

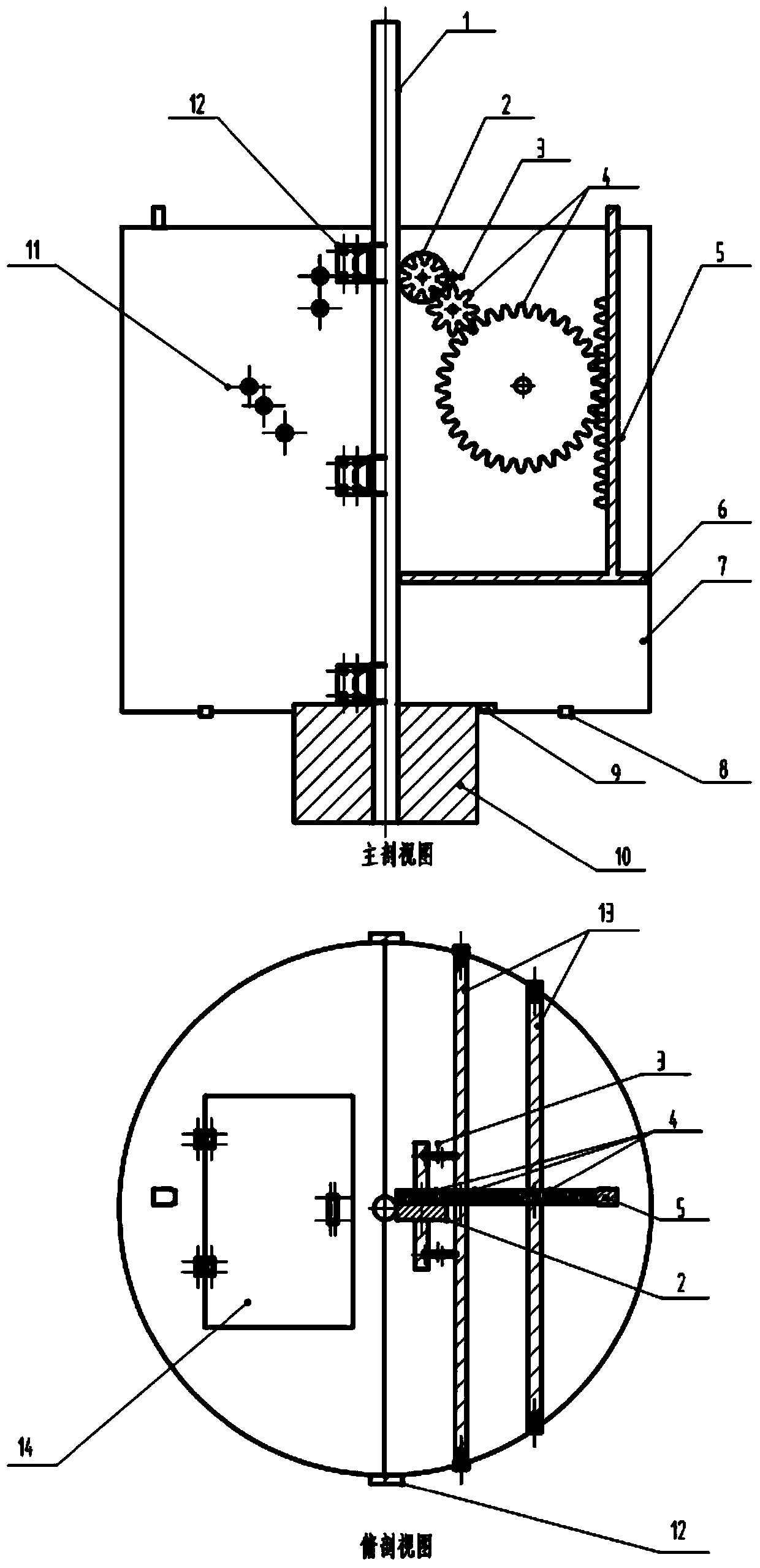

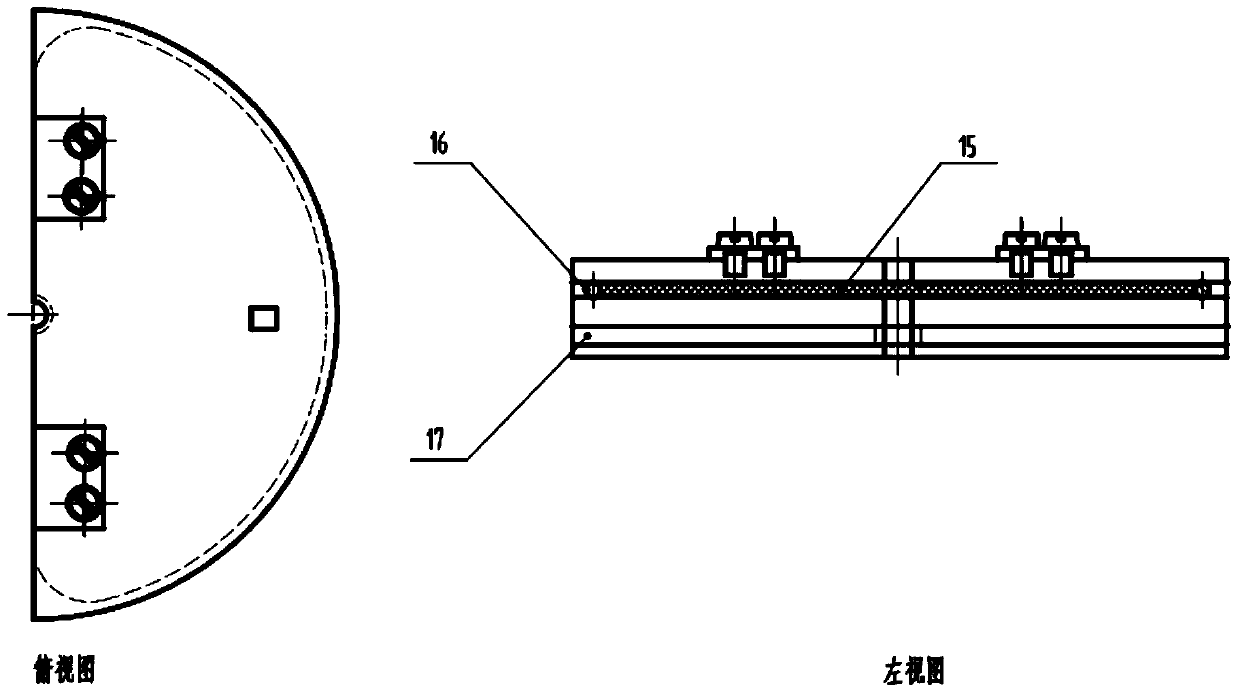

[0011] (1) if figure 1 As shown, the anti-leakage device box has two semi-cylindrical structures, which are fixed above the packing box 10 by fixing buckles 12 , and the sealing rubber ring 9 is used to seal the leak-proof device and the outer wall of the packing box 10 . There is a gear fixing hole 11 on the casing, and the length of the adjustable gear shaft 5 strokes increases sequentially from top to bottom by changing the large gears of three kinds of radii. The radius ratios of the small gear and the large gear in the gear combination 4 are 1:9, 1:10, and 1:12, which match the strokes of conventional pumping units of 3m, 3.6m, and 4.2m.

[0012] (2) if figure 1 As shown, the polished rod 1 moves upward, driving the roller 2 to rotate clockwise; the gear shaft 5 moves downward through the gear combination 4 changing direction; the gear shaft 5 drives the sealing baffle 6 to move downward, compressing the The gas achieves a sealing effect.

[0013] (3) if figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com