Vertical lifting and unloading working device of loader

A vertical lift and loader technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of reducing the working efficiency of the loader working device, affecting the flexibility and stability of the equipment, affecting the lifting height and distance, etc. The effect of compact structure, enlarged rise height, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

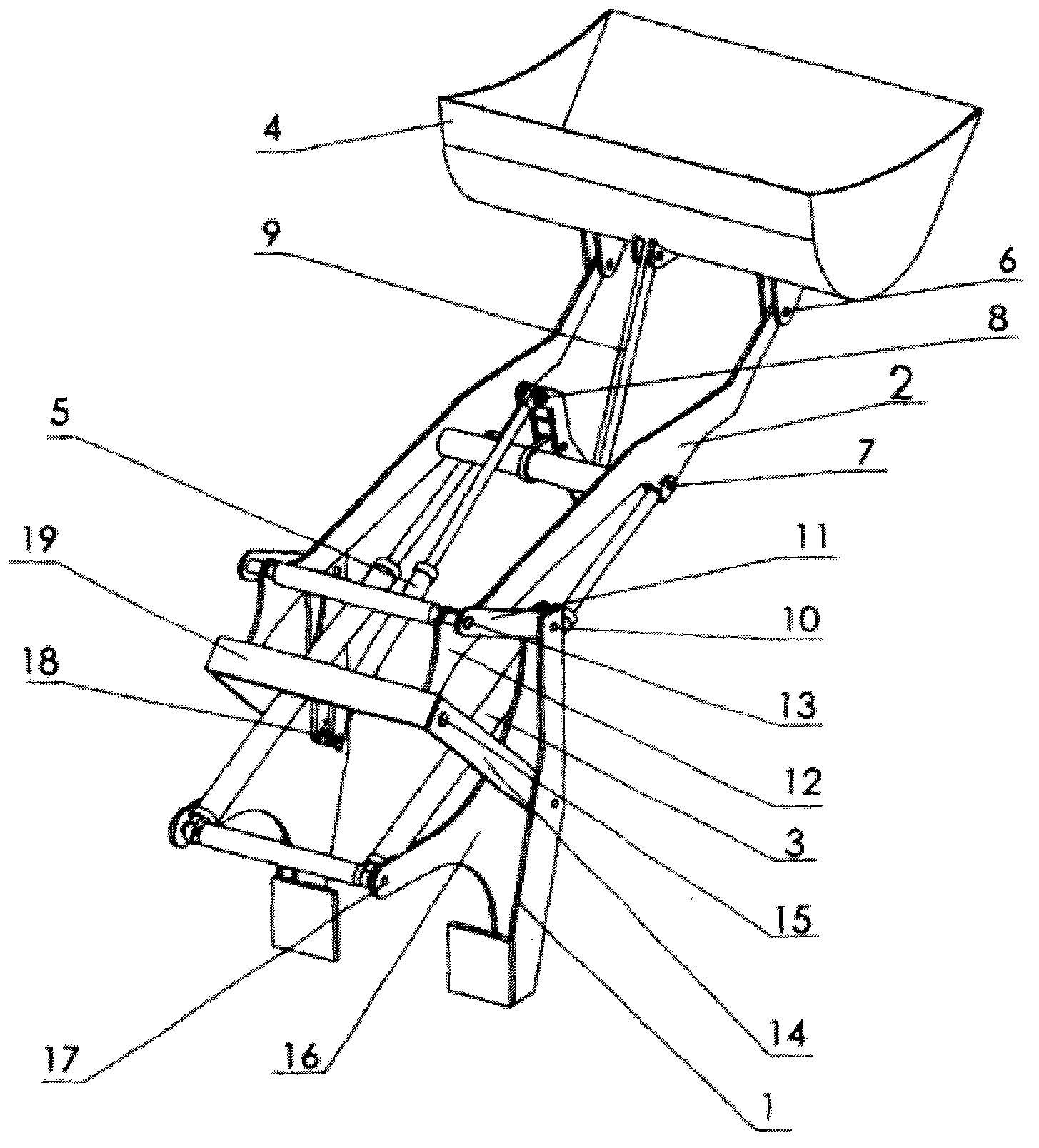

[0011] Such as figure 1 figure 2 image 3 Figure 4 As shown, the vertical lifting and unloading working device of the loader is composed of a fixed bracket 1, a boom 2, a boom cylinder 3, a bucket 4, and a bucket turning cylinder 5; the front end of the boom 2 is hinged through the bottom of the bucket 6 Connected to the bottom of the bucket 4, the front end of the telescopic rod of the boom cylinder 3 is connected to the middle of the boom 2 through the hinge shaft 7 in the middle of the boom, and the front end of the telescopic rod of the bucket flip cylinder 5 passes through the hinge shaft 8 at the rear end of the flip connecting rod 9 It is connected with the flip link 9 on the rear side of the bucket 4, and the upper rotating handle 11 is connected to the upper part of the fixed bracket 1 through the hinge shaft 10 at the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com