Surface active agent in steel wire pickling solution

A technology of surfactant and pickling solution, which is applied in the field of surfactant, can solve the problems of reducing the adhesion between bead wire and rubber, the unevenness of the surface of the steel wire, and affecting the service life of the bead wire, so as to save acid Washing time, thorough removal, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

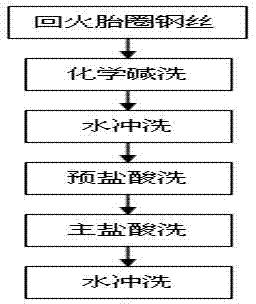

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: A kind of surfactant used in steel wire pickling solution, which is composed of nonylphenol polyoxyethylene ether and sodium lauryl sulfate, after it is prepared with hydrochloric acid to form pickling solution, nonylphenol polyoxyethylene The mass percentages of vinyl ether, sodium lauryl sulfate and hydrochloric acid in the hydrochloric acid pickling solution are 0.006%, 0.01% and 4% respectively, and the tempered steel wire of 0.96 mm is treated with the above-mentioned pickling solution containing surfactant. Pickling for 4 seconds can increase the release speed and expansion area of hydrochloric acid in the pickling solution, improve the utilization rate of hydrochloric acid in the pickling solution, increase the pickling speed by 6%, and improve production efficiency; Compared with pickling solution, after pickling with surfactant, the oxide skin on the surface of steel wire is more thoroughly removed, and the surface is more uniform. After electrol...

Embodiment 2

[0015] Embodiment two: a kind of surfactant that is used in steel wire pickling solution, is made of sodium dodecylbenzenesulfonate and sodium dodecyl sulfate, after it is formulated with hydrochloric acid to form pickling solution, dodecyl The mass percentages of sodium benzenesulfonate, sodium lauryl sulfate and hydrochloric acid in the hydrochloric acid pickling solution are 0.10%, 0.06% and 9% respectively. The pickling of the steel wire for 4 seconds can increase the release speed and expansion area of hydrochloric acid in the pickling solution, improve the utilization rate of hydrochloric acid in the pickling solution, increase the pickling speed by 8%, and improve production efficiency; Compared with the pickling solution with surfactant, after pickling with surfactant, the oxide skin on the surface of steel wire is more thoroughly removed, and the surface is more uniform. After chemical plating, the adhesion between steel wire and rubber is greater than 1100N.

Embodiment 3

[0016] Embodiment 3: A kind of surfactant used in steel wire pickling solution, which is composed of nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether and sodium lauryl sulfate, which is prepared with hydrochloric acid to form pickling solution Finally, the mass percentages of nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, sodium lauryl sulfate and hydrochloric acid in the hydrochloric acid pickling solution are 0.16%, 0.17%, 0.45% and 9%, respectively, using the above The pickling solution containing surfactant pickles the 1.20mm tempered steel wire for 5 seconds, which can increase the release speed and expansion area of hydrochloric acid in the pickling solution, improve the utilization rate of hydrochloric acid in the pickling solution, and increase the acidity. The washing speed is 12%, which improves the production efficiency; compared with the pickling solution without surfactant, the oxide skin on the steel wire surface is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com