Turning buffering mechanism for photovoltaic module flexible manufacturing system

A flexible manufacturing system and caching mechanism technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of large space occupation, easy-to-collision components, etc., achieve stable rotation, precise control, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

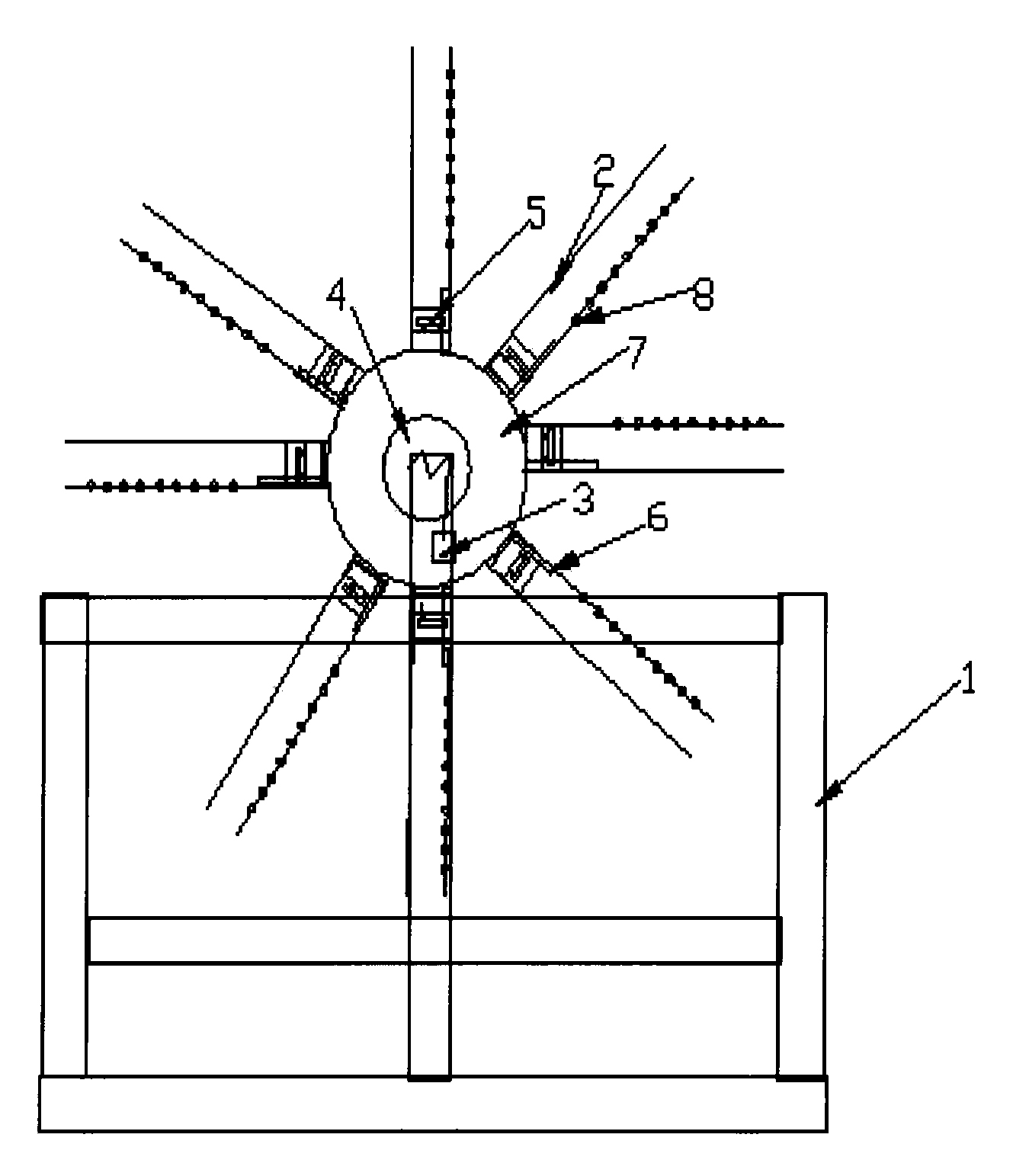

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0023] like figure 1 As shown, a flip buffer mechanism for automatic and flexible manufacturing of photovoltaic modules fixes the aluminum profile frame 1 through corner brackets and screws, and connects the air expansion shaft 4 with the aluminum profile frame 1 through bolts and connecting plates. Install the blue and roller 7 on the air shaft 4, then install the servo motor 3, connect the assembly bearing plate 2 to the air shaft 4, then fix the cylinder 5 and the guide rail 6 on the assembly bearing plate 2, and then install the fluent The strip 8 is mounted on the module carrier plate 2 .

[0024] The operation method of the above-mentioned...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap