Vortex extrusion type large-plastic deformation device

A large plastic deformation, extrusion technology, applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve the problems of high device requirements and complex implementation technology, and achieve the effect of eliminating sliding and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

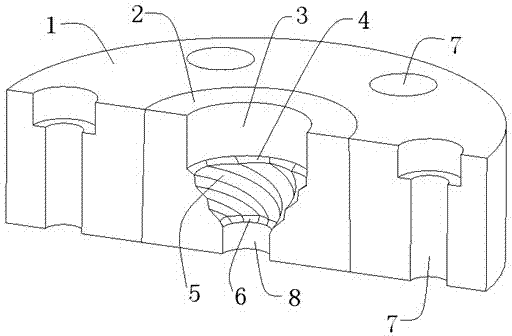

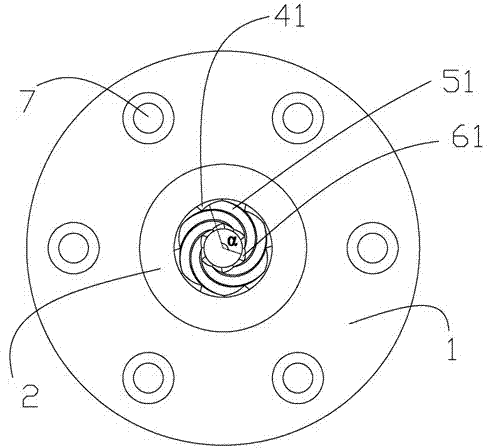

[0018] Such as Figure 1-3 As shown, a scroll extrusion type large plastic deformation device of the present invention includes a main body of the device, and the main body of the device includes an outer layer reinforcement ring 1 and an inner layer die 2 that is interference fit with the outer layer reinforcement ring 1. The layer die 2 is provided with a torsion extrusion cavity, which is in the shape of shrinking from the upper port to the lower port, and the surface of the torsion extrusion cavity is provided with a twisting deformation zone, and the twisting deformation zone includes The deformation belt 5 is formed alternately by several belt-shaped protrusions, the upper end of the belt-shaped protrusions can extend to the upper port of the twisting extrusion chamber, and the lower end of the belt-shaped protrusions can extend to the bottom of the twisting extrusion chamber Port; the width of the upper end of the strip-shaped protrusion is greater than the width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com