Liquid processing apparatus using electrodeless-discharge ultraviolet ray irradiation apparatus

A liquid treatment and ultraviolet technology, applied in the direction of light water/sewage treatment, gas discharge lamp parts, discharge lamps, etc., can solve the problems of ensuring gaps, large leakage, difficult discharge, etc., to reduce high-frequency power loss , high-efficiency ultraviolet radiation, and the effect of reducing maintenance times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

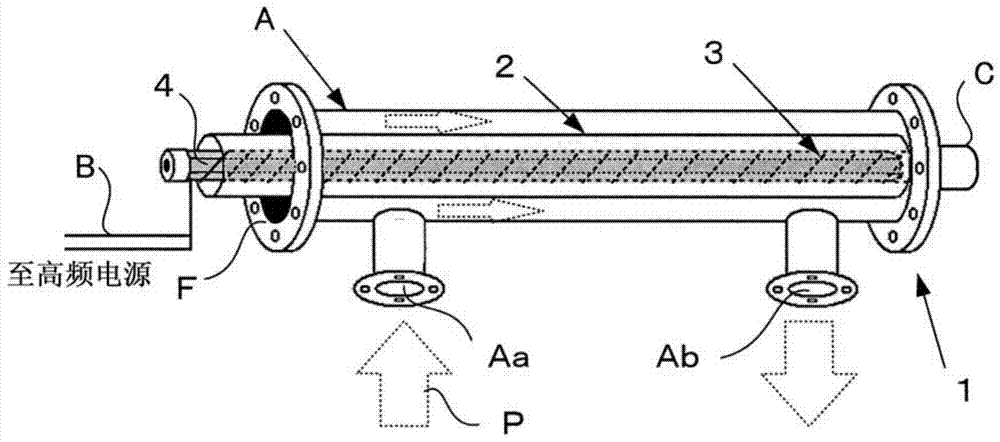

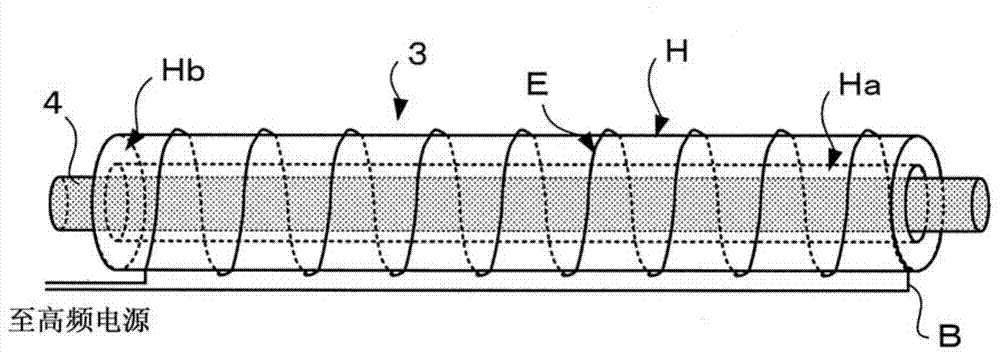

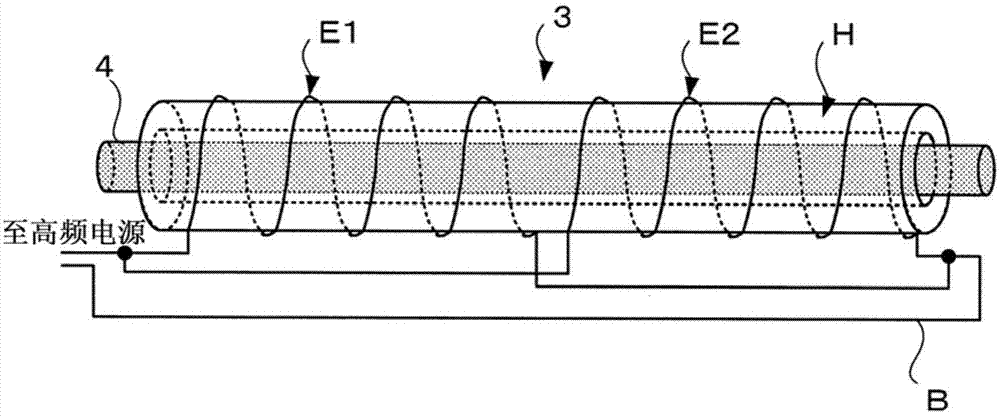

[0026] figure 1 It is a conceptual diagram showing an embodiment of the liquid processing device according to the present invention. figure 1 The shown liquid processing device 1 is of the following type: For example, in a cylindrical container A made of a material that is hard to corrode, such as stainless steel, the following figure 2 or image 3 The protective outer tube 2 of the shown electrodeless discharge ultraviolet irradiation device 3 uses the ultraviolet rays emitted from the electrodeless discharge ultraviolet irradiation device 3 to process the treatment liquid P passing between the cylindrical container A and the protective outer tube 2. deal with.

[0027]Both ends of the cylindrical container A are liquid-tightly sealed by the sealing portion F so that the processing liquid P does not leak to the outside, thereby forming the following flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com