Method for determining axle load stability factor of composite rod piece

A composite material and stability coefficient technology, applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as inapplicability, and achieve the effect of reducing accidents, accurate determination, and high scientific credibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

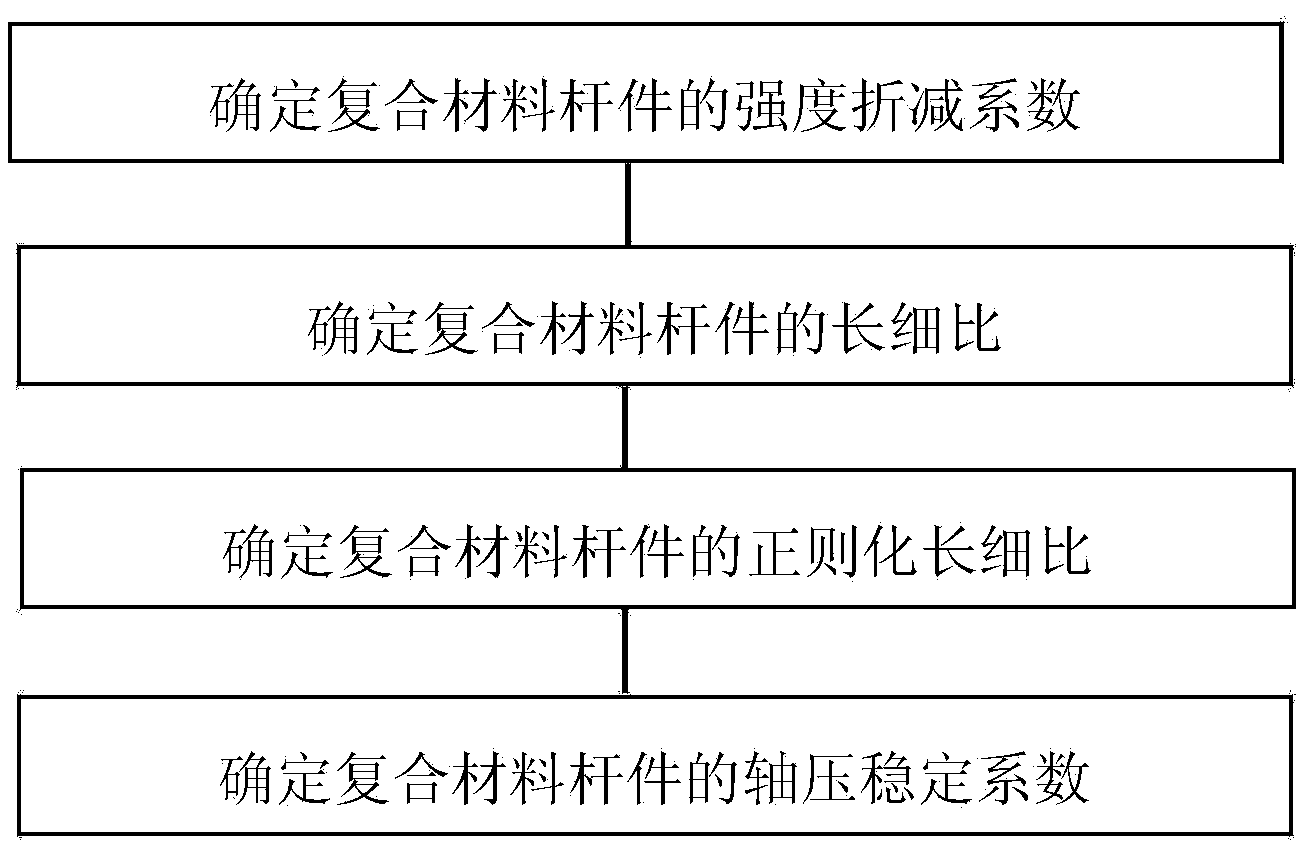

[0039] Such as figure 1 As shown, the method for determining the axial compression stability coefficient of the inventive composite member of this example includes the following steps:

[0040] (1) Determine the slenderness ratio of the composite member;

[0041] (2) Determine the regularized slenderness ratio of the composite member;

[0042] (3) Determine the strength reduction factor of the composite member;

[0043] (4) Determine the axial compression stability coefficient of the composite member.

[0044] The slenderness ratio λ in the step (1) is determined by formula (1):

[0045] λ = μl i - - - ( 1 )

[0046] In the formula, μ is the length factor value of the bar, l is the length of the bar, and i is the section moment of inertia of the bar.

[0047] The regularized slenderness ratio in step (2) Determined by formula (2): ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com