A long-life urban stone landscape road pavement structure

A long-life, slate technology, applied in the field of municipal engineering, can solve problems such as crushing, prolonging the construction period, difficult maintenance, etc., to achieve the effect of improving life, ensuring walking safety, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Take new build as an example.

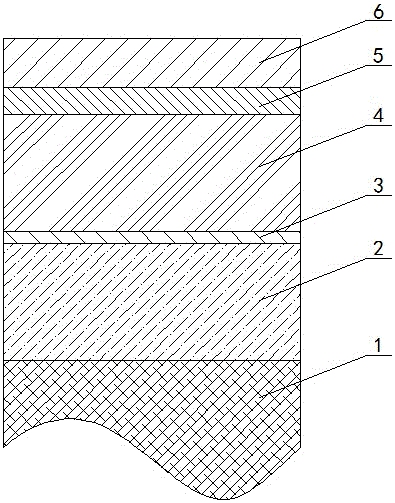

[0022] as attached figure 1 As shown, the stone road of the urban pedestrian street is from bottom to top, consisting of soil foundation 1, 10cm lime stabilized soil layer 2, 1cm asphalt macadam seal layer 3, 10cm flexible asphalt stabilized macadam base layer 4, 2cm asphalt sand layer 5 and flagstone layer 6 is laid.

[0023] The specific implementation steps and technical requirements are as follows:

[0024] Lay a 10cm-thick lime-stabilized soil layer 2 on the compacted and flat soil foundation 1, and maintain it in the specified curing period to meet the strength requirements of the standard design;

[0025] After the lime-stabilized soil layer 2 reaches the design strength, lay a 1cm-thick asphalt macadam seal layer 3 on it, and roll it with a steel drum roller;

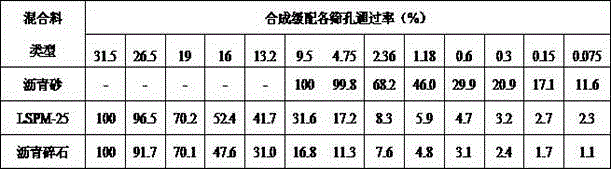

[0026] Lay a 10cm thick flexible asphalt stabilized gravel base 4 (LSPM-25) on the asphalt gravel seal 3;

[0027] A 2 cm densely graded asphalt sand layer 5 is laid on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com