Production method of natural organic seaweed fertilizer

A production method and organic fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of harsh fermentation and extraction environment, reduced decomposition of effective components of fertilizers, and increased cost of extracting seaweed fertilizers, so as to achieve convenient field fertilization and less The effect of low usage and working environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

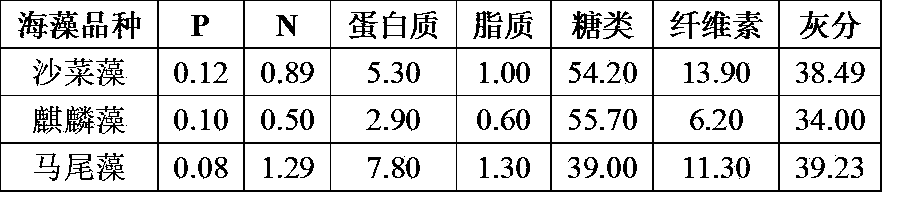

[0025] Take 300 kg of Kylin Algae (calculated as dry vegetables), wash them, smash them into a homogenate, pour them into a reactor with a capacity of 5000L, and use a solution of lye with a KOH:NaOH ratio of 0.4 to treat them. After 4 hours, adjust the seaweed slurry The PH can be close to neutral, then add 10-60 times of boiling water, stir at 70-98°C for 7 to 10 hours to make the seaweed boil and dissolve, then filter and concentrate under reduced pressure until it becomes a semi-solid slurry, which contains water The water content is about 80%, and it is dried in the sun to obtain a seaweed extract with a water content of about 25%. According to the mass ratio, it is seaweed extract: urea: diamine phosphate: potassium sulfate=11:522:85:81, compounded into organic seaweed fertilizer, sieved with 900 mesh screen, extruded and granulated in flat mode to produce columnar The particles are then rounded twice by a rounding machine, screened by a vibrating screen, and then enter ...

Embodiment 2

[0027] Take 300 kg of algae (calculated as dry vegetables), wash them, grind them and homogenize them, pour them into a reaction kettle with a volume of 5000L, and use a solution of lye with a KOH:NaOH ratio of 0.5 to treat them. After 3 hours, adjust the seaweed The pH of the slurry can be close to neutral, then add 10-60 times of boiling water, stir at 70-98°C for 7 to 10 hours to make the seaweed boil and dissolve, then filter and concentrate under reduced pressure until it becomes a semi-solid slurry, at this time The water content is about 80%, and it is dried in the sun to obtain seaweed extract with a water content of about 25%. According to the mass ratio, it is seaweed extract: urea: monoamine phosphate: potassium sulfate=12:479:122:75, compounded into organic seaweed fertilizer, sieved with 900 mesh screen, extruded and granulated in flat mode to produce columnar The particles are then rounded twice by a rounding machine, screened by a vibrating screen, and then ente...

Embodiment 3

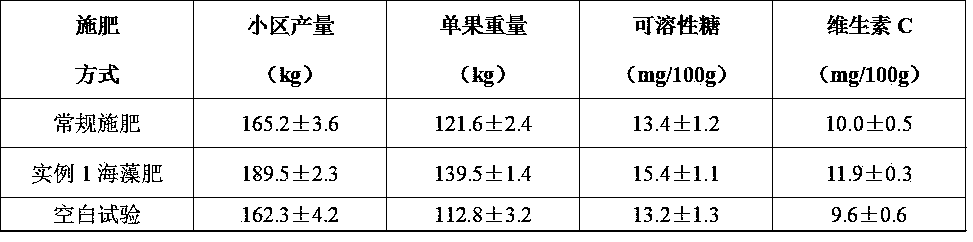

[0029] The experiment site is in Nanjing County, Zhangzhou City, Fujian Province. The soil for testing is red soil, which contains 1.82% soil organic matter, available N 60.6mg / kg, and available P 12.1mg / kg. The vegetable variety is cucumber, which is divided into 15 experimental areas, each with an area of 22m 2 , planted at a plant spacing of 0.4m*1.1m, 50 plants per plot.

[0030] Fertilization method:

[0031] (1) According to local customs, conventional fertilization is 4500kg / mu of base fertilizer farmyard manure, 25kg / mu of urea, 25kg / mu of diammonium phosphate, 10kg / mu of potassium sulfate, topdressing three times, and 20kg / mu of urea each time;

[0032] (2) Example 1 seaweed fertilizer, base fertilizer farmyard manure 4500kg / mu, seaweed fertilizer 60kg / mu, topdressing three times, applying seaweed fertilizer 15kg / mu each time;

[0033] (3) Blank test, the base fertilizer is farmyard manure 4500kg / mu, equal weight of water.

[0034] Table 2 Field experiments (g / 100g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com