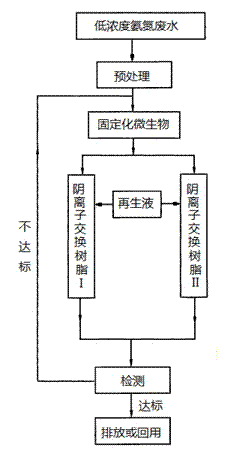

A treatment process for low-concentration ammonia nitrogen wastewater

A low-concentration ammonia nitrogen and treatment process technology, which is applied in the field of wastewater treatment and low-concentration ammonia nitrogen wastewater treatment process, can solve the problems of slow proliferation of nitrifying bacteria, large power consumption, and high operating costs, and achieve high promotion and application value. The effect of extending the regeneration cycle and reducing resin consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Sampling of a slightly polluted source water in Guangzhou showed that the concentration of ammonia nitrogen was 12 mg / L, and the treatment of source water with low concentration of ammonia nitrogen included the following steps:

[0023] Pretreatment: Take 100 L of ammonia nitrogen wastewater and filter it with quartz sand layer to remove most of the suspended solids and some organic pollutants.

[0024] Immobilized microbial nitrification process: mix sodium alginate, nitrifying bacteria concentrate, and water in a ratio of 1.5:2:1, and then add it dropwise to 3% calcium chloride solution. After curing for 10 minutes, the polymerized gel The glue was taken out from the calcium chloride solution, washed with deionized water, and added to the immobilized microbial reactor according to the filling rate of 15%, and the dissolved oxygen concentration in the reactor was maintained at 4 mg / L. The above-mentioned pretreated wastewater is sent to the immobilized microbial reacto...

Embodiment 2

[0029] The final effluent of a sewage treatment in Jiangsu was sampled to detect that the concentration of ammonia nitrogen was 35 mg / L, and the treatment of low-concentration ammonia nitrogen wastewater included the following steps:

[0030] Pretreatment: Take 100 L of ammonia nitrogen wastewater and filter it with quartz sand layer to remove most of the suspended solids and some organic pollutants.

[0031] Immobilized microbial nitrification process: Mix sodium alginate, nitrifying bacteria concentrate, and water in a ratio of 2:3:1 and add dropwise to 3% calcium chloride solution. After curing for 5 minutes, the polymerized gel is removed from the Take it out of the calcium chloride solution, wash it with deionized water, and add it to the immobilized microbial reactor according to the filling rate of 20%, and keep the dissolved oxygen concentration in the reactor at 6mg / L. The above-mentioned pretreated wastewater is sent to the immobilized microbial reactor, and after a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com