Process for treating and recycling mine acid heavy metal wastewater

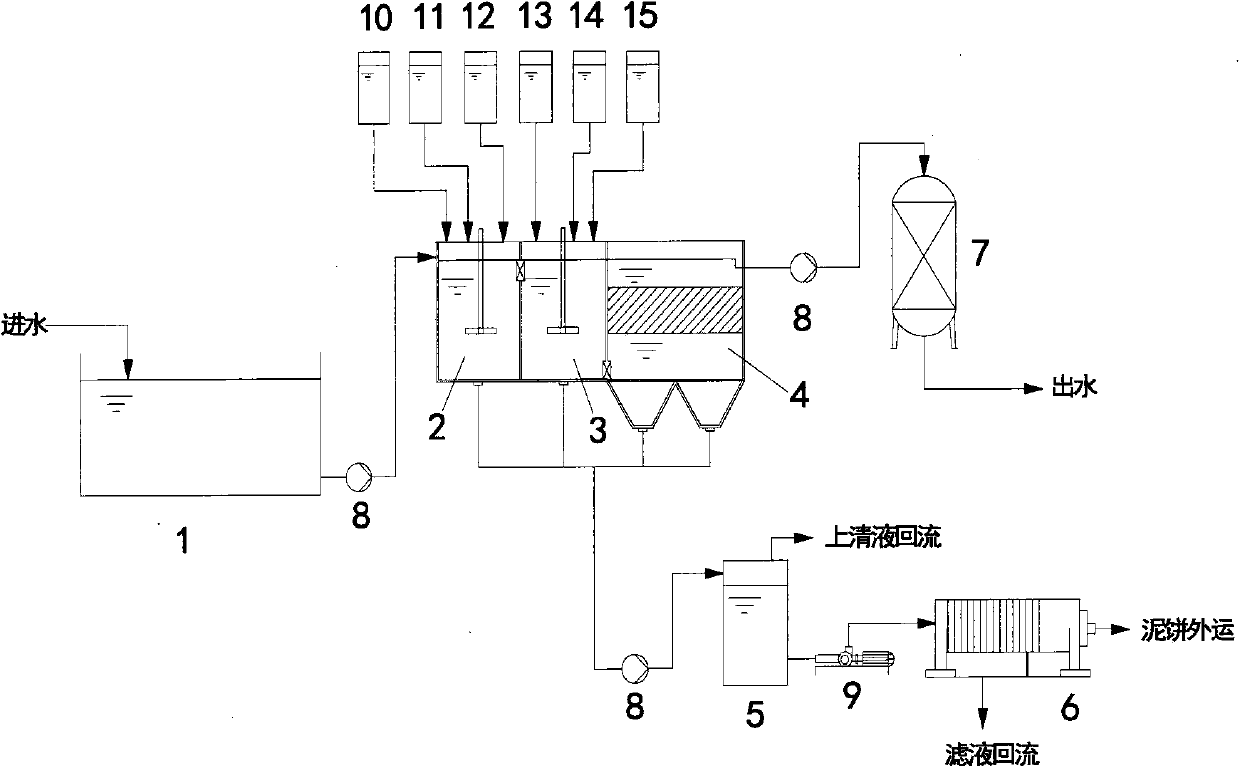

A mine acid wastewater and wastewater treatment technology, applied in the removal of nickel ions and fluoride ions, mine acid heavy metal wastewater treatment and reuse process, copper, and iron in wastewater fields, can solve production and life losses, and threaten the safety and ecology of the surrounding environment system, low pH, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A mining enterprise discharges 80t / d of acidic heavy metal wastewater, and the specific water quality indicators are as follows:

[0023] Unit: mg / L

[0024] water quality index

[0025] The waste water is treated by adopting the process of the present invention, specifically, the waste water is introduced into an integrated reaction precipitation system, and after the process of dosing, stirring, reaction, flocculation and precipitation is completed, the supernatant is treated through an activated carbon filter tank. After being monitored by a third-party professional organization, the water quality after treatment is shown in the table below:

[0026]Unit: mg / L

[0027] water quality index

[0028] The water quality meets the requirements of "Urban Sewage Recycling Industrial Water Quality" (GB / T19923-2005), and can be reused as cleaning water.

Embodiment 2

[0030] A mining enterprise discharges 50t / d of acidic heavy metal wastewater, and the specific water quality indicators are as follows:

[0031] Unit: mg / L

[0032] water quality index

[0033] Using the process of the present invention, waste water is introduced into an integrated reaction and precipitation system, and after the processes of dosing, stirring, reaction, flocculation and precipitation are completed, the supernatant is treated by an activated carbon filter tank. Monitored by the local environmental protection bureau, the water quality indicators at the outlet of the activated carbon filter tank are shown in the table below.

[0034] Unit: mg / L

[0035] water quality index

[0036] The water quality meets the requirements of "Urban Sewage Recycling Industrial Water Quality" (GB / T19923-2005), and can be reused as cleaning water in the production process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com