Workshop level material transport trolley control system and manipulation method thereof

A technology of material trolley and conveying trolley, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., to achieve the effect of simple and convenient operation, convenient unified scheduling, and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

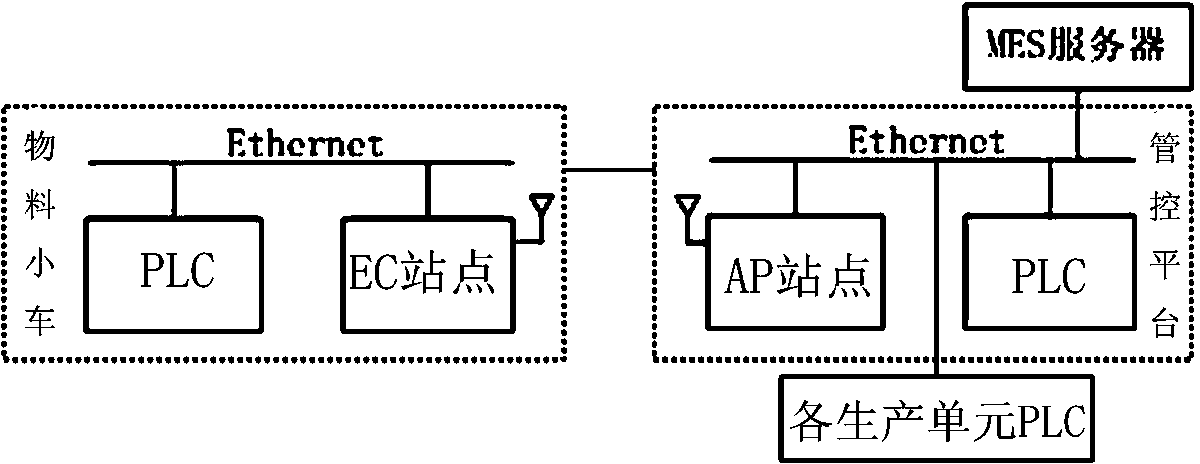

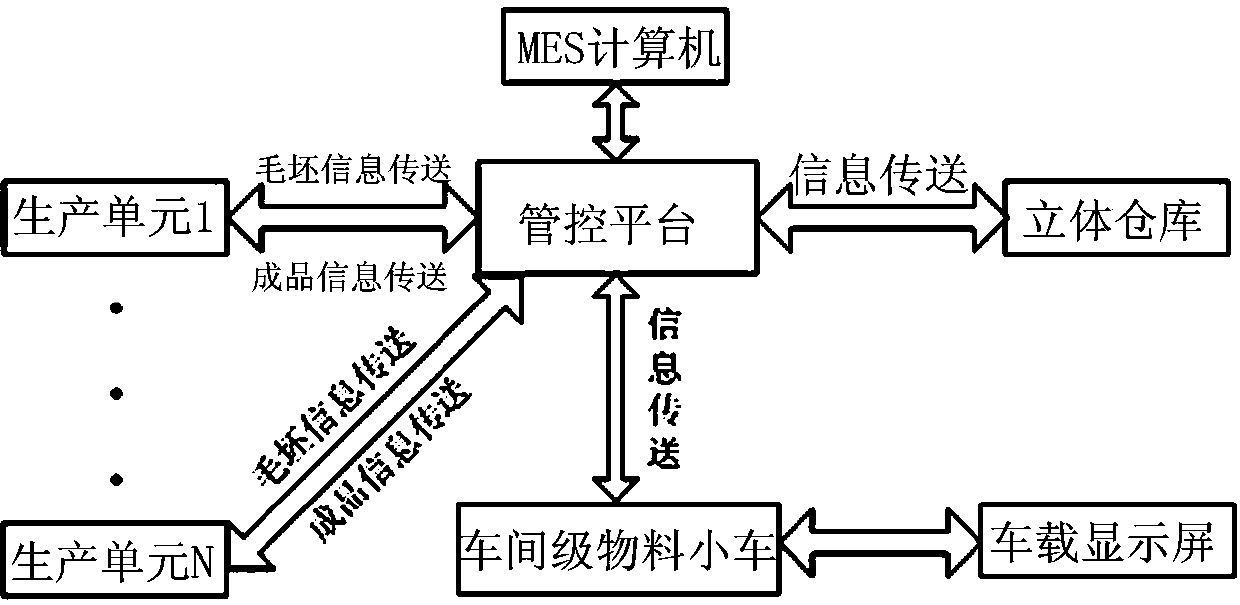

[0033] The control system of the workshop-level material conveying trolley includes a trolley control box, a management and control platform and a wireless communication module. The management and control platform communicates wirelessly with the material trolley through the wireless access terminal installed on its control cabinet; the control platform communicates with each production unit through The optical fiber ring network connection can not only exchange information with each production unit but also exchange and process data with the manufacturing execution management system (MES system).

[0034] A wireless communication module (that is, a wireless client), a car control box and an on-board display are installed on the material trolley. The trolley control box is installed in the body of the material trolley, and the trolley control box is equipped with a PLC controller and an input / output module. The PLC controller described above communicates with the wireless commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com