Assembling platform and method of parallel robot

An assembly platform and robot technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., to achieve the effect of fast speed, good consistency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will become more obvious and easy to understand by describing the implementation manners of the present invention in conjunction with the following drawings.

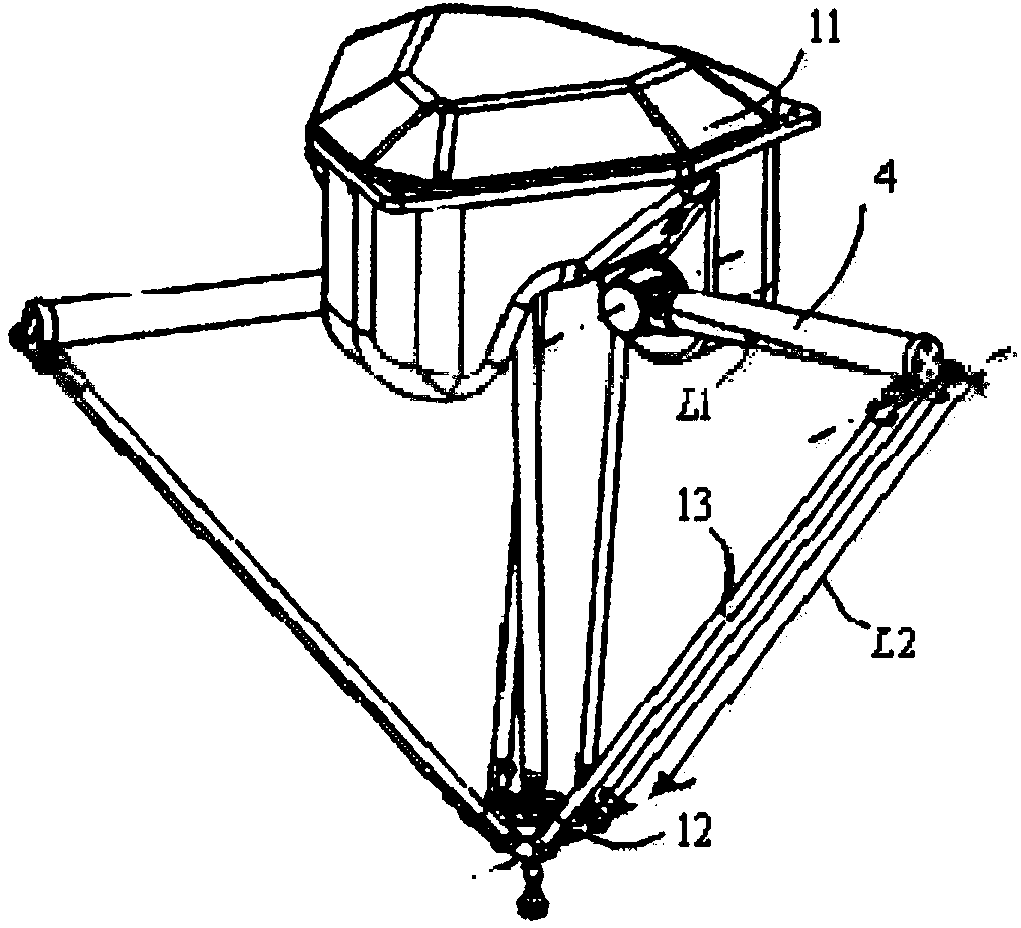

[0037] Reference attached figure 1 , the structure of the Delta parallel robot is as follows:

[0038] The mechanism includes a static platform 11, a dynamic platform 12 and three branch chains connecting the two platforms. The three branch chains have the same structure and are arranged symmetrically at 120°. Every branch chain is made up of driving rod 4 and driven rod 13. The driving rod 4 and the static platform 11 are up and down rotating pairs, the driving rod 4 and the driven rod 13 are connected by a Hooke hinge, and the driven rod 13 and the moving platform 12 are also connected by a Hooke hinge.

[0039] Both the driving rod 4 and the driven rod 13 are made of carbon fiber tube material, and their two ends are connected by high-strength adapters. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com