Locating plate of sheet structure

A technology of sheet structure and positioning plate, which is applied in the direction of turning equipment, tool holder accessories, metal processing equipment, etc., to achieve the effect of ensuring positioning accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

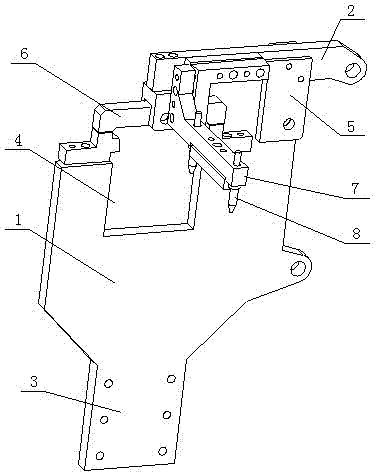

[0009] Such as figure 1 As shown, the positioning plate with sheet structure described in the embodiment of the present invention includes an overturning beam 2 and a positioning plate 1, the bottom of the positioning plate 1 is a connecting plate 3 with a plurality of bolt holes, and the top of the positioning plate 1 is provided with There is a notch 4, the right side of the flip beam 2 is hinged with the positioning plate 1 through the support plate 5, the flip beam 2 is fixedly connected with the support plate 5, and the left side of the flip beam 2 is connected with a door The center of the shaped seat 6 is connected, and the door-shaped seat 6 is docked with the notch 4 of the positioning plate; a thimble holder 7 is installed on the side of the flip beam 2, and a thimble holder 7 is installed on the bottom of the thimble holder 7 Two downwardly positioned thimbles 8 , the position of which is opposite to the position of said notch 4 .

[0010] The sheet structure posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com