efficient mop

A mop and high-efficiency technology, which is applied in the field of mop cleaning the ground or other surfaces, can solve the problems of inability to change the wet surface cloth, complicated installation, and reduced cleaning efficiency, so as to prolong the time of cleaning and replacing the mop, prolong the cleaning time, and increase the clip area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation

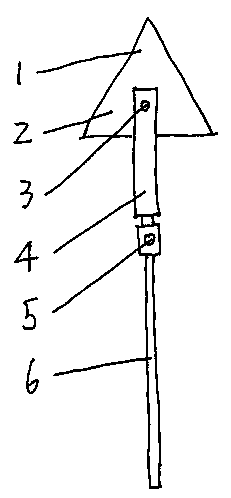

[0012] Refer to attached figure 1 , rocking arm shaft 3 is established on the two end faces of triangular runner 1, and three plate surfaces of triangular runner 1 form mopping surface 2, and the interior of mopping surface 2 is connected with rocking arm shaft 3 by beam. Two rocking arms 4 are folded out at the two ends of a metal plate, and the metal plates connecting the two rocking arms form the beam of the rocking arm. The rocker shafts 3 are connected to form a hinge. Universal joint 5 rear end is connected with mop bar 6.

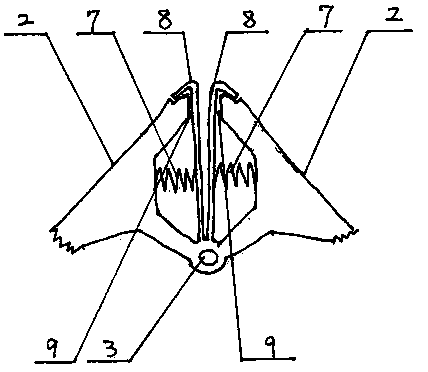

[0013] Refer to attached figure 2 , Cleaning cloth fixing device embodiment one, set clip groove 9 on three corners of triangular runner 1, cleaning cloth fixing device is located in clip groove 9, and fixing device is the clip 8 that two steel plates and several springs 7 are formed , the clip 8 is clamped by the elastic force produced by the spring 7 to clamp the cleaning cloth inserted between the two clips 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com