Preserved fruit kernel removing mechanism

A candied fruit and denucleating needle technology, applied in the field of candied fruit denucleation mechanism, can solve the problems of employee injury and low efficiency of manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

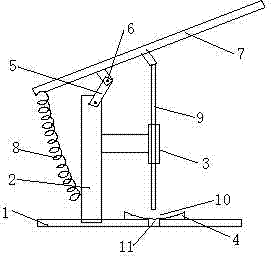

[0010] Combine below figure 1 Specific description embodiment:

[0011] A candied fruit pitting mechanism, comprising a base plate 1, characterized in that, the base plate 1 is provided with a support 2, and the middle part of the support 2 is provided with a hollow positioning sleeve 3 and a core removal workbench 4, and the support The upper part of 2 is hinged with two splints 5, and the two splints 5 are respectively arranged on both sides of the bracket 2, and the upper ends of the two splints 5 are connected by a pin 6, and the rotation of the pin 6 is connected with a rocker 7. One end of the rocking lever 7 is connected with a tension spring 8, and the other end of the tension spring 8 is fixed on the lower part of the support 2, and the rocking lever 7 is hinged with a coring needle 9. Nucleation needle 9 passes through hollow positioning sleeve 3 and is positioned at denucleation workbench 4. Wherein said denucleating workbench 4 is provided with an arc-shaped groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com