Bow spring system for dual mass flywheels and dual mass flywheels

A bow spring system and dual-mass flywheel technology, applied in spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve problems such as difficult three-stage direction, failure to achieve vibration reduction behavior, etc., to avoid free angle or Dead zone, simple torsional vibration, and improved spring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

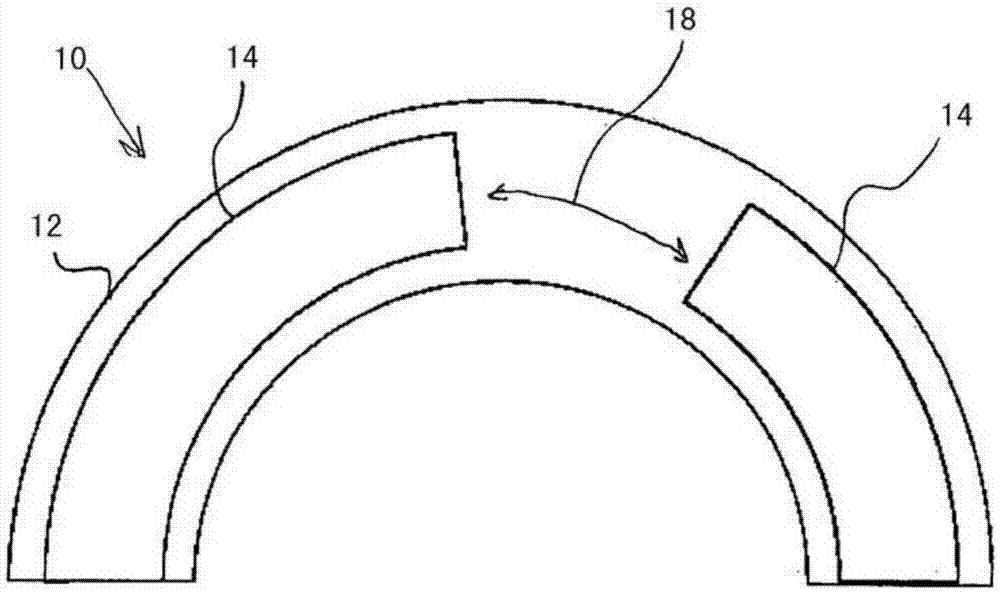

[0025] exist Figure 4 The bow spring system 10 according to the invention shown in has a starting bow spring 22 designed as an outer spring, relative to which starting bow spring 22 is arranged radially inwardly coaxially to the starting bow spring 22 one after the other in series There is a first additional bow spring 24 and a second additional bow spring 24 . The first additional bow spring 24 can be suspended on the first end 28 . Correspondingly, the second additional bow spring 26 can be suspended on the second end 30 . The bow spring system 10 can be used as an energy storage element for a dual mass flywheel in order to damp torsional vibrations without large energy losses.

[0026] In the illustrated embodiment, the first additional bow spring 24 has a length L in the illustrated relaxed state 1 , which is longer than the length L of the second additional bow spring 26 2 longer so that the second additional bow spring 26 can be compressed earlier than the first add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com