A casing for a wind power pipe busbar

A technology for wind power tubes and shells, which is applied to conductors, circuits, insulated cables, etc., can solve the problems of high investment costs, achieve the effects of reducing busbar inductance, improving busbar rigidity, and improving busbar current-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

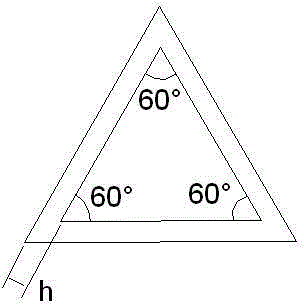

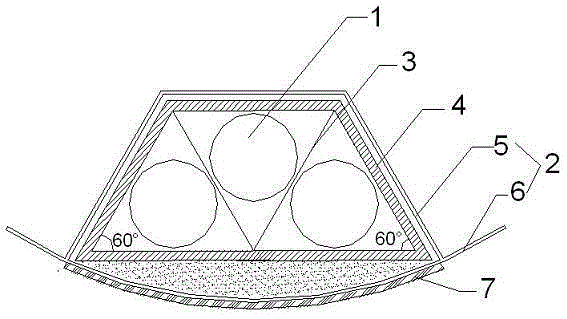

[0015] As shown in the figure, a shell of a wind power pipe busbar includes a protective shell 2, and the protective shell 2 is provided with three positioning shells 3, and the positioning shell 3 is an equilateral triangle, and its thickness h is 3-8mm , the three positioning shells 3 are alternately placed, fixed by the fixing device 4 into an isosceles trapezoid with a base angle of 60°, the protective shell 2 includes an upper shell 5 and a bottom plate 6, and the upper shell 5 is Isosceles trapezoid, the shape and size of the upper casing 5 matches the shape and size of the isosceles trapezoid formed by the three positioning casings 3, the bottom plate 6 is an arc structure, and the bottom plate 6 and the fixing device 4 The space is filled with elastic elements, and the outer wall of the base plate 6 is provided with a layer of cushioning pad 7, and the central ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com