Hardware-in-loop test device and method for vehicle-mounted charger control device of new energy automobile

A technology for on-board chargers and new energy vehicles, which is applied in electrical testing/monitoring, etc., and can solve problems such as high power consumption in testing, inability to simulate faults in the AC charging process, and vehicle damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

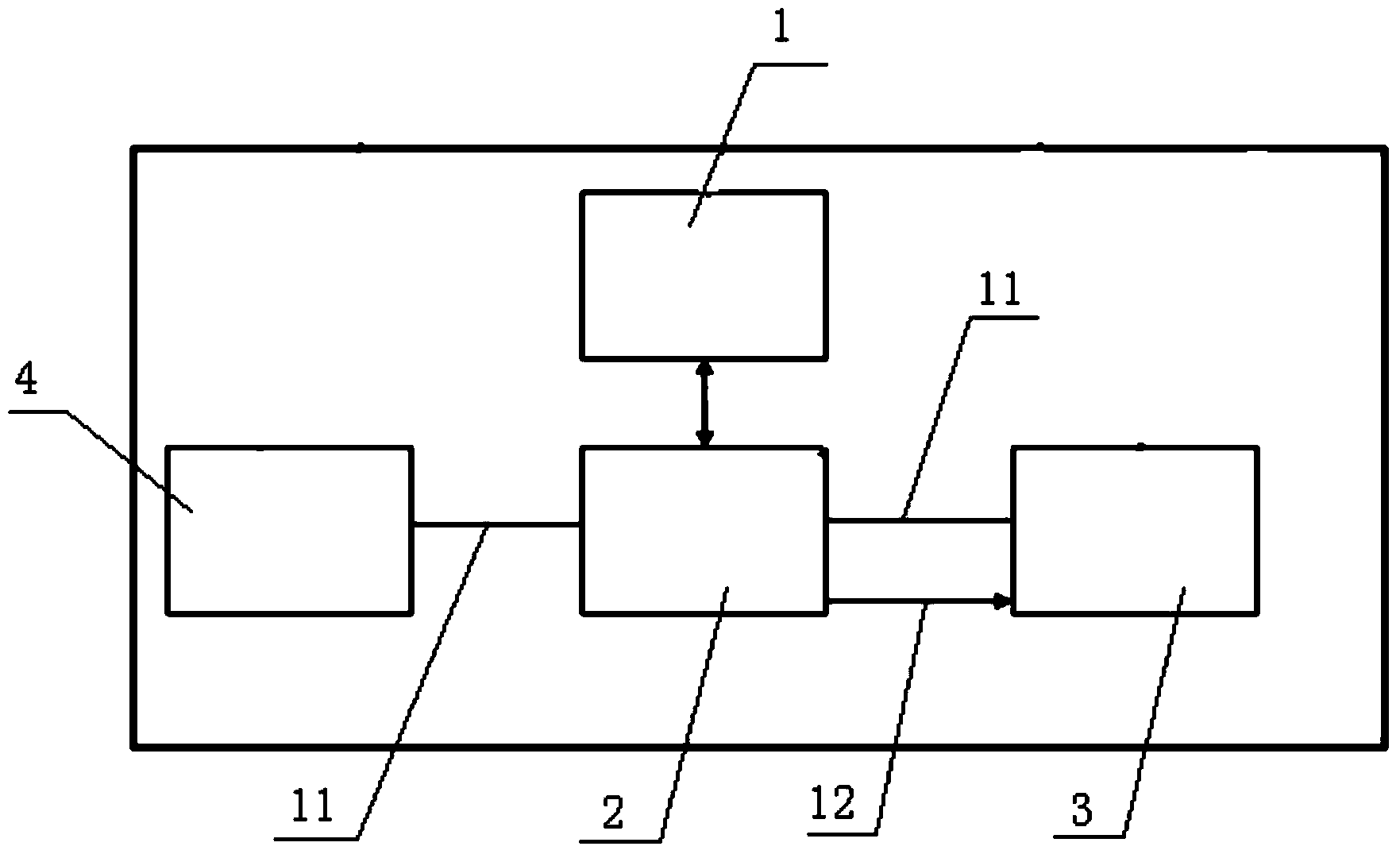

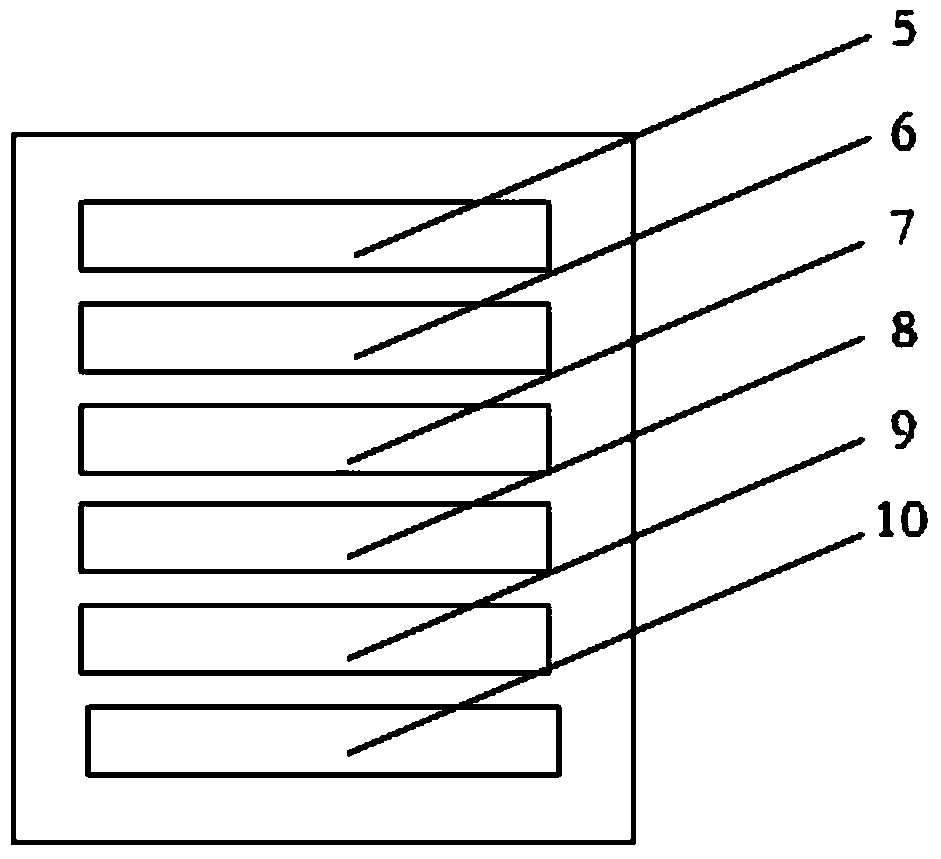

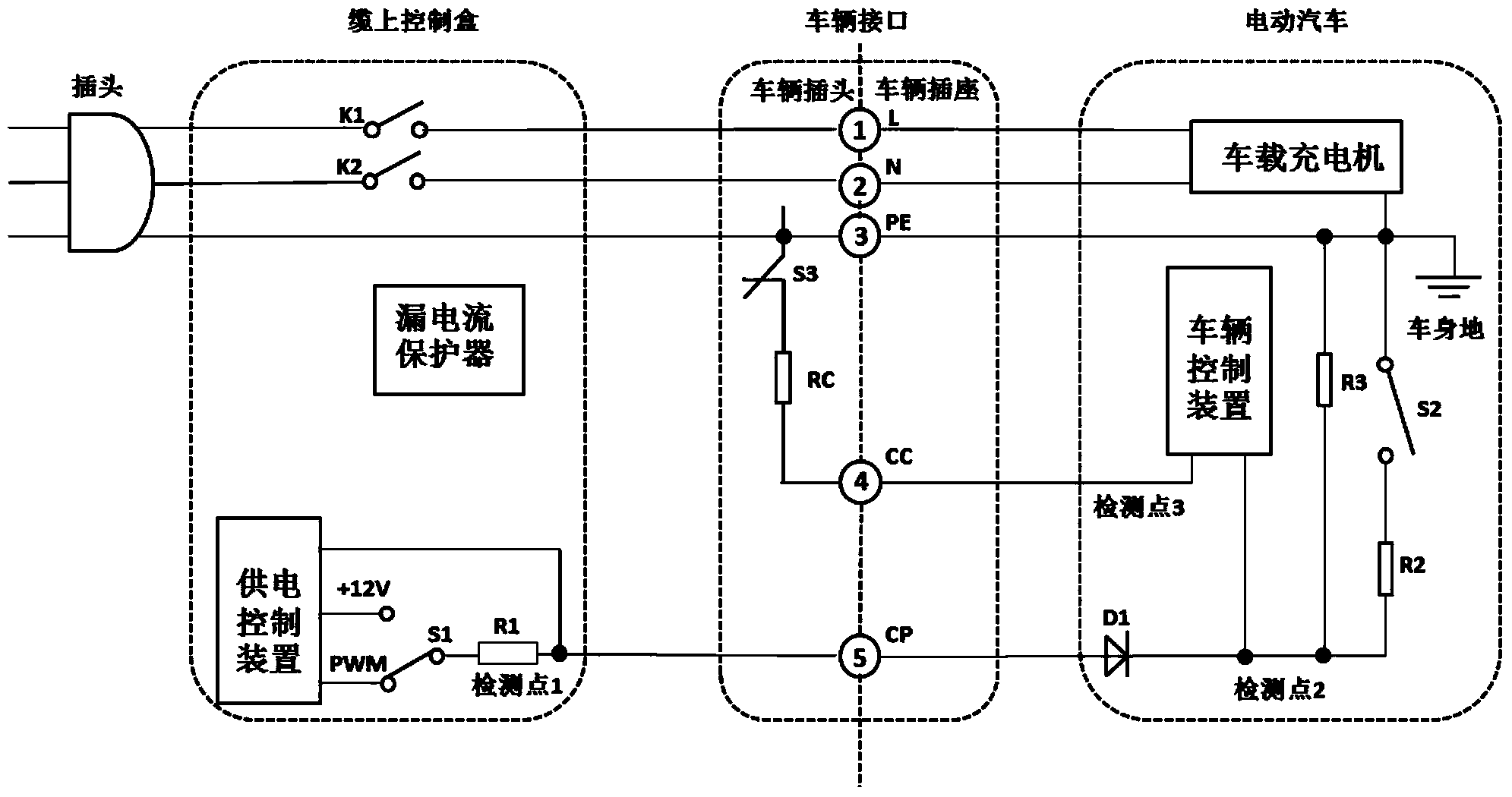

[0034] Such as Figure 1-4 As shown, the new energy vehicle on-board charger control device and the battery management system hardware-in-the-loop test equipment described in the embodiment of the present invention include a test host computer interface 1, a LABCAR system 2, an on-board charger control device 3, and a battery management system 4 , the LABCAR system 2 includes a programmable power supply 5, a real-time simulation computer 6, a resistance signal simulation board 7, a bus signal simulation board 8, a fault simulation board 9 and a PWM signal simulation board 10; the test host computer interface 1 The LABCAR system 2 is connected through a network cable, and the LABCAR system 2 communicates with the on-board charger control device 3 and the battery management system 4 through CAN bus 11 , PWM signal 12 and digital control signals respectively.

[0035] The hardware-in-the-loop test method for the on-board charger control device of the new energy vehicle described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com