Integrated assembly type hollow slab bridge and construction method thereof

A technology of hollow slab bridges and hollow slabs, applied in bridge construction, bridges, buildings, etc., can solve problems such as bridge deck cracks, poor lateral integrity, and limited ability to transmit shear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

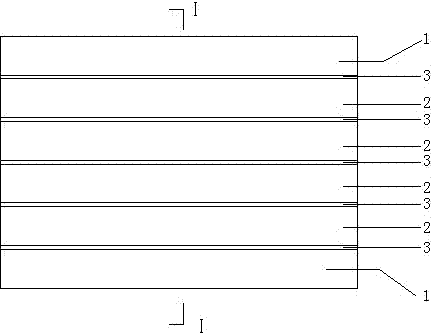

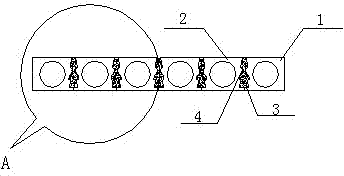

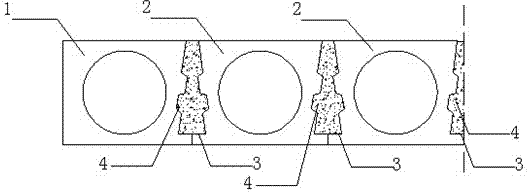

[0027] An assembled integral hollow slab bridge, comprising two oppositely arranged hollow slab side plates, a hollow slab middle plate is continuously laid between the two hollow slab side plates, and the adjacent hollow slabs (that is, the hollow slab side plate and the hollow slab middle plate) Between the slabs and between the middle slabs of two hollow slabs) is provided with grooved joint concrete, on both sides of the grooved joint concrete there are 1 to 3 shear blocks along the height of the slab, and the height of the (lowest) shear block is not low At 5 cm, the shear block is longitudinally long in groove shape or convex shape, and when the number of shear blocks is more than two, the groove shape and convex shape shear blocks are arranged alternately.

[0028] The construction method of the above-mentioned assembled integral hollow slab bridge comprises the following steps:

[0029] (1) Prefabricated reinforced concrete or prestressed concrete hollow slab: first de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com