Workpiece orientation device with push rod

A technology of orienting device and push rod, which is applied in the direction of conveyor objects, transportation and packaging, etc., and can solve problems such as inability to realize workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

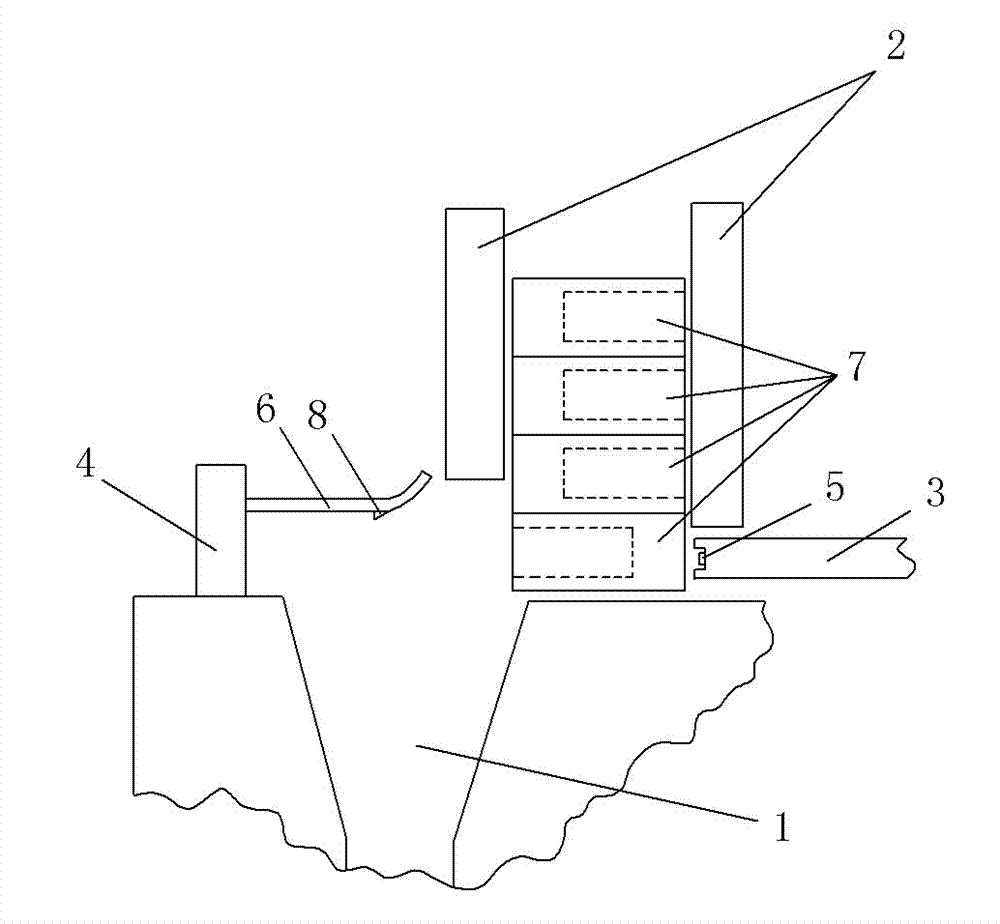

[0009] The reference signs in the accompanying drawings of the specification include: a positioning groove 1 , a feeding chute 2 , a push rod 3 , a baffle 4 , an infrared probe 5 , an elastic pressure plate 6 , a workpiece 7 , and a blocking piece 8 .

[0010] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0011] Such as figure 1 As shown, a workpiece orientation device with a push rod includes a frame, a positioning groove 1 arranged on the frame, a feeding chute 2, a push rod 3 and a baffle 4, the push rod 3 is connected with a driving device, and the drive The device is preferably a propulsion cylinder, the feeding chute 2 is arranged on one side of the positioning groove 1, the bottom of the feeding chute 2 is provided with a reciprocating push rod 3, and the other side of the positioning groove 1 opposite to the push rod 3 is provided with a stopper. The plate 4 and the end of the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com