Transmission mechanism with multiple chute inclined surfaces

A technology of transmission mechanism and chute, which is applied in the field of multi-chute inclined-plane transmission mechanism, which can solve the problems that the transmission mechanism cannot be adapted, and the stepped cylindrical or tapered workpiece cannot be oriented to transmit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

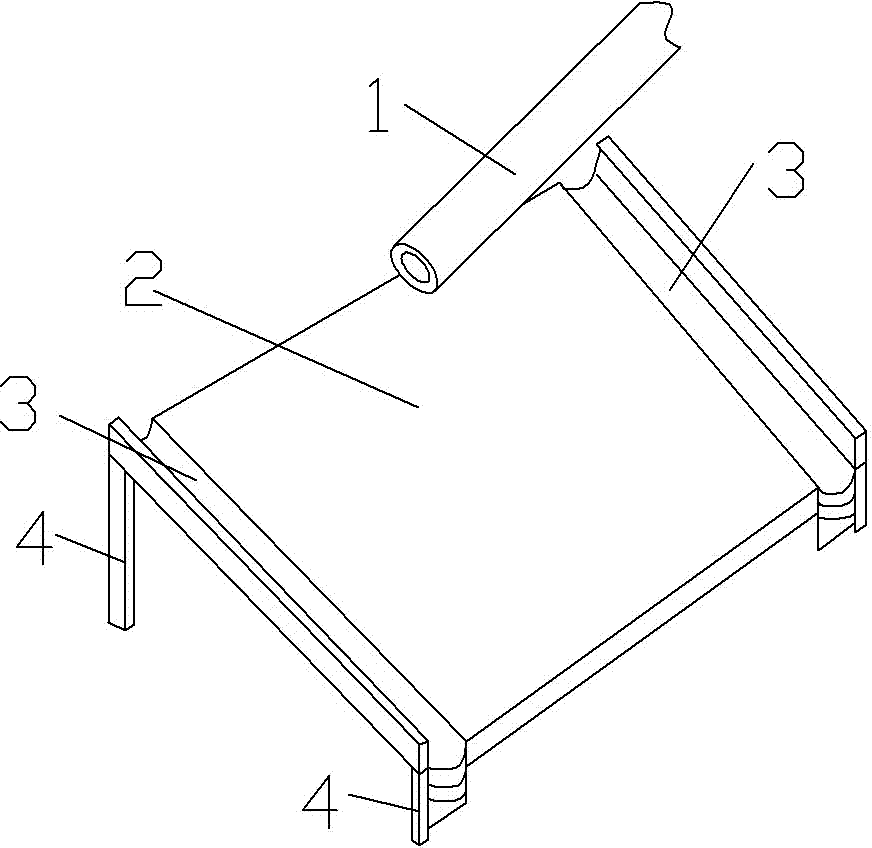

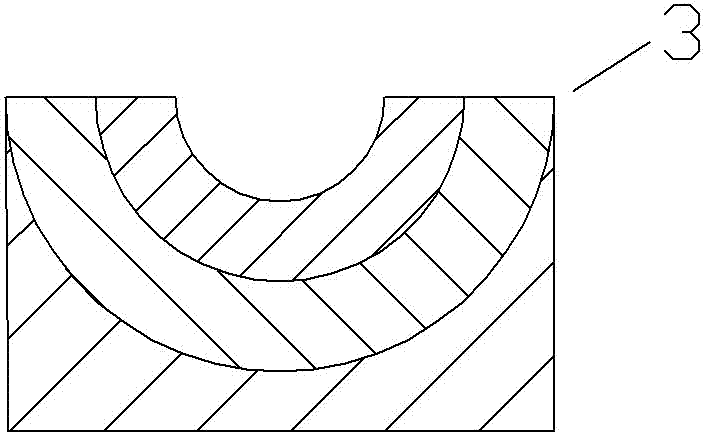

[0011] The reference signs in the accompanying drawings of the description include: feeding chute 1 , inclined plate 2 , conveying chute 3 , and support rod 4 .

[0012] Below in conjunction with accompanying drawing and embodiment technical solution of the present invention is described in further detail:

[0013] Such as figure 1 , figure 2 As shown, a multi-chute inclined-plane transmission mechanism includes a feeding chute 1 and an inclined flat plate 2, the feeding chute 1 is arranged on the top of the inclined flat plate 2, and a transmission chute 3 is respectively arranged on both sides of the inclined flat plate 2, and the inclined flat plate 2 The direction of inclination is perpendicular to the feeding axis of the feed chute 1. The transfer chute 3 includes three stacked grooves with different radii. The radii of the three grooves are 1mm, 2mm, and 3mm in sequence. There are through holes, the positions of the through holes of the three stacked grooves coincide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com