Magnetic-levitation superconductive rolling mill

A magnetic levitation and superconducting technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve problems such as camber, edge waves, and unreasonable structures of plates, and achieve mechanical friction, high flatness, and effect of rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

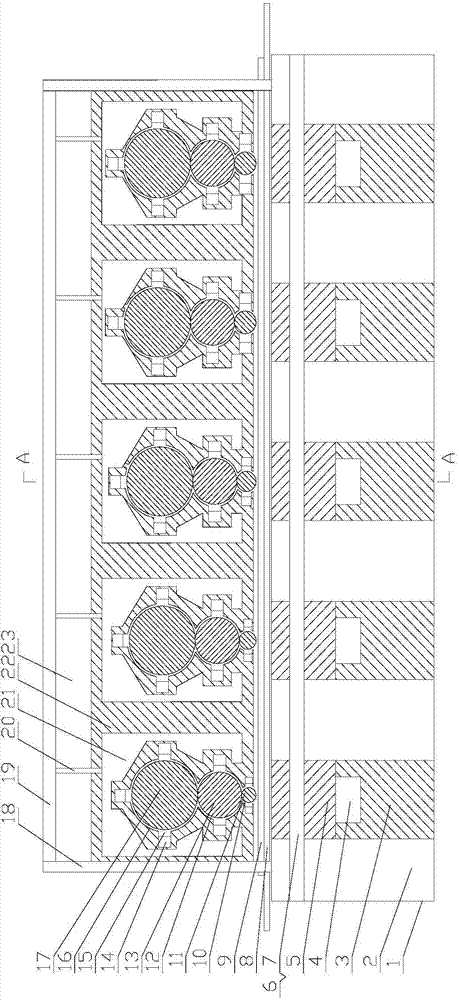

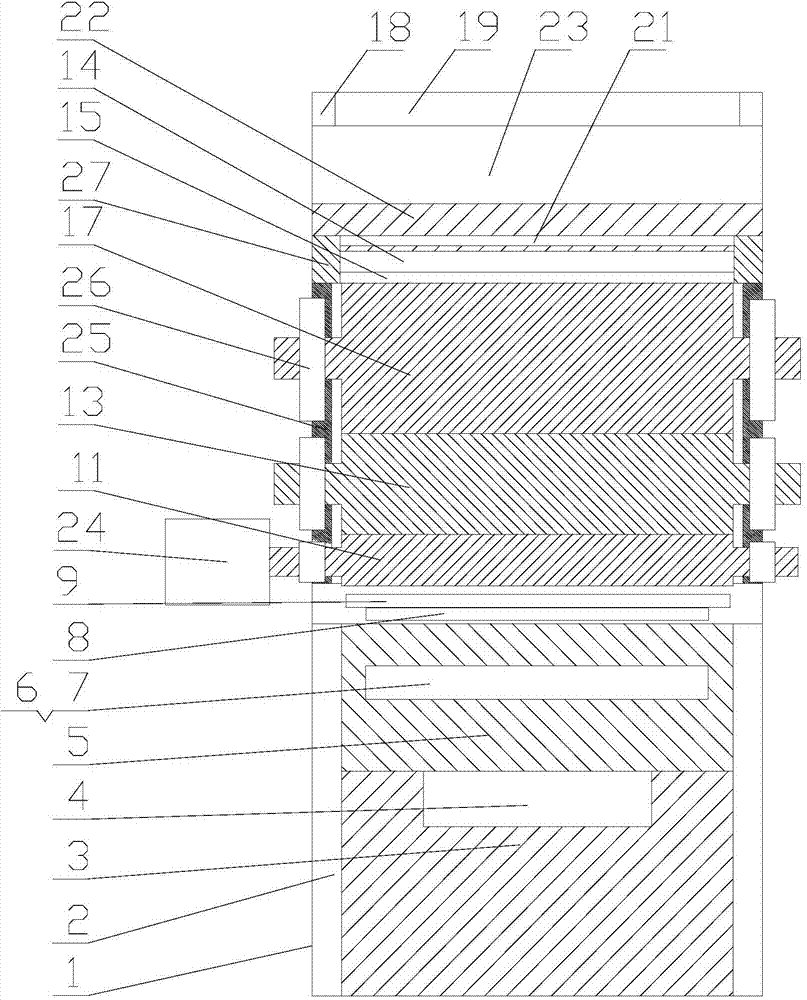

[0043] The specific embodiment of the present invention is as shown in the accompanying drawings, comprising a rolling platform, a rolling mechanism and a running channel for steel plates to be rolled; Plate running channel; characterized in that: the rolling mechanism is installed on the upper part of the rolling platform through the upper bracket 19; a servo hydraulic device 23 is installed on the upper part of the rolling mechanism;

[0044]The pressing platform includes a lower tank body 1, a support pad 3, a permanent magnet I4, and a rolling module 5; the lower tank body 1 is a tank structure with an open upper part, and an oil film base 2 and a plurality of support pads 3 are installed inside it. A permanent magnet I4 is embedded in the upper part of the supporting pad 3, and the rolling module 5 is adsorbed on the upper part of the supporting pad 3 through the permanent magnet I4; the rolling module 5 is processed with an electromagnetic track groove 6, and the electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com