Quick hot-line by-pass jumper removing operation method for 10kV insulated power distribution line

A technology of drainage lines and lines, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as smaller and smaller gaps between lines, safety risks for operators, small turning space, etc., to avoid unnecessary economic and social losses, The effect of expanding the work items and scope of work and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

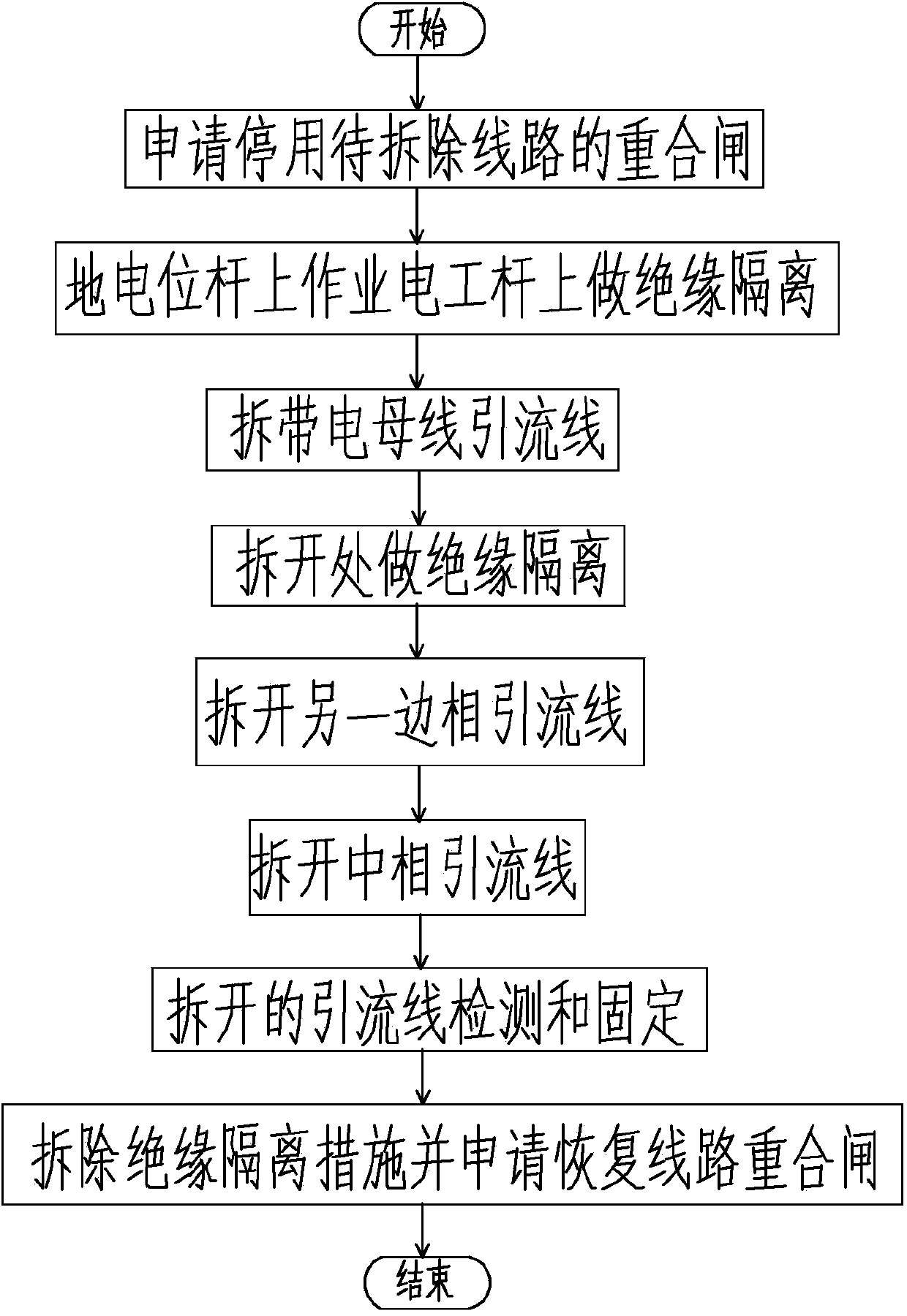

Image

Examples

Embodiment 1)

[0017] In this embodiment, the 10kV power distribution insulated line is quickly charged to remove the drain wire operation method, which adopts the ground potential operation method.

[0018] The following corresponding preparations are required before operation:

[0019] 1. Staff composition:

[0020] The operating personnel include: 1 person in charge of the work, 1 electrician working on the ground potential on the pole, and 2 electricians working on the ground.

[0021] 2. Prepare relevant main operating tools:

[0022] 2 pairs of T-shaped wire shielding covers;

[0023] 3 pieces of rubber insulation blanket;

[0024] 6 resin insulation blankets;

[0025] 6 insulating blanket clips;

[0026] Ground potential insulated wire insulation stripper 1 set;

[0027] 3 non-load-bearing connection clamps for ground potential operation;

[0028] 1 insulating operating rod;

[0029] 1 insulating assembly rod;

[0030] 3 insulation lock rods;

[0031] 1 high voltage electros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com