Ventilating system of heavy current circuit-breaker equipment

A technology of ventilation system and circuit breaker, applied in the field of ventilation system, can solve the problems of increasing the heat of the busbar, economic loss, equipment impact, etc., and achieve the effect of reducing the contact area, ensuring the use environment, and prolonging the life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

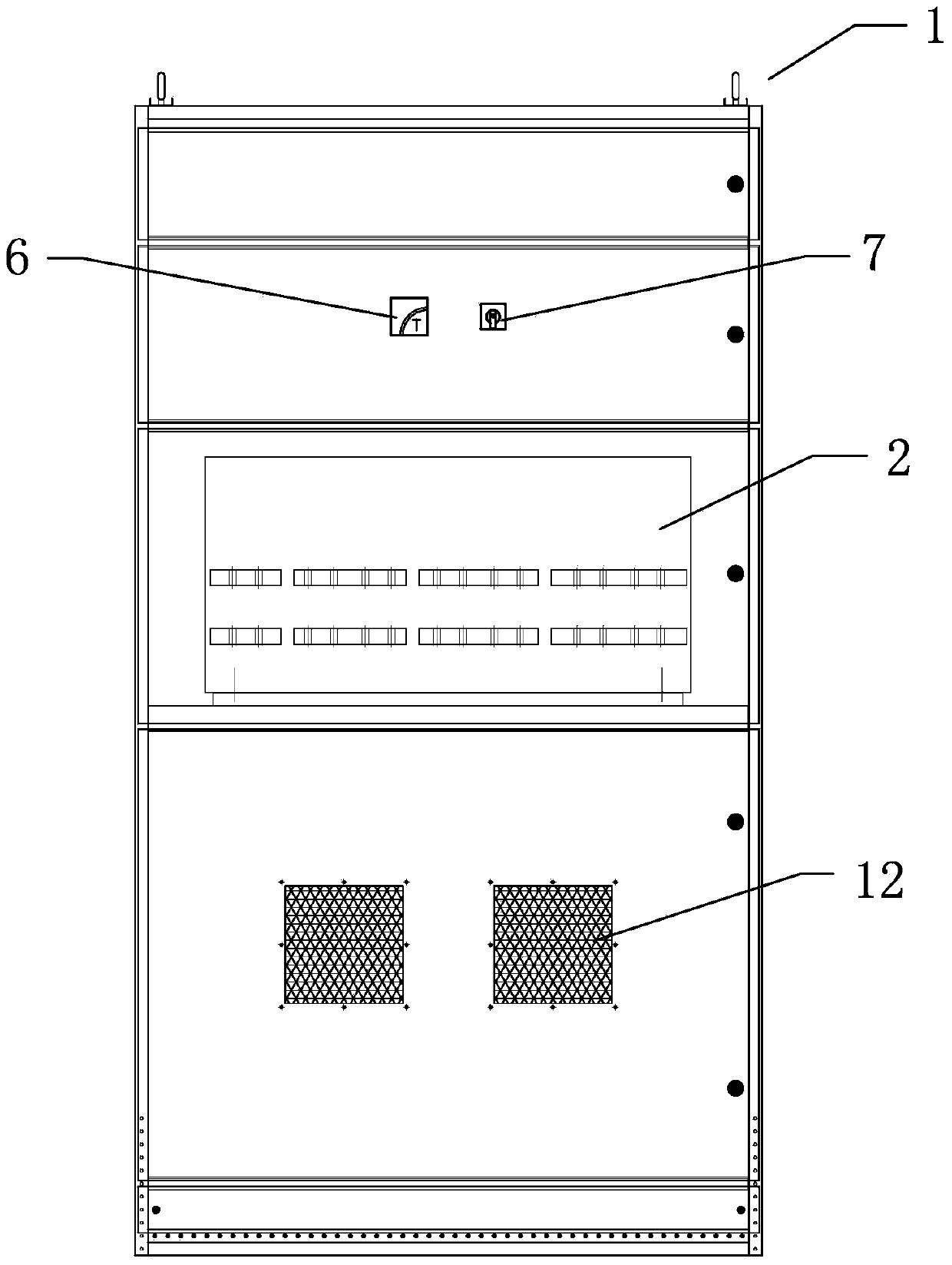

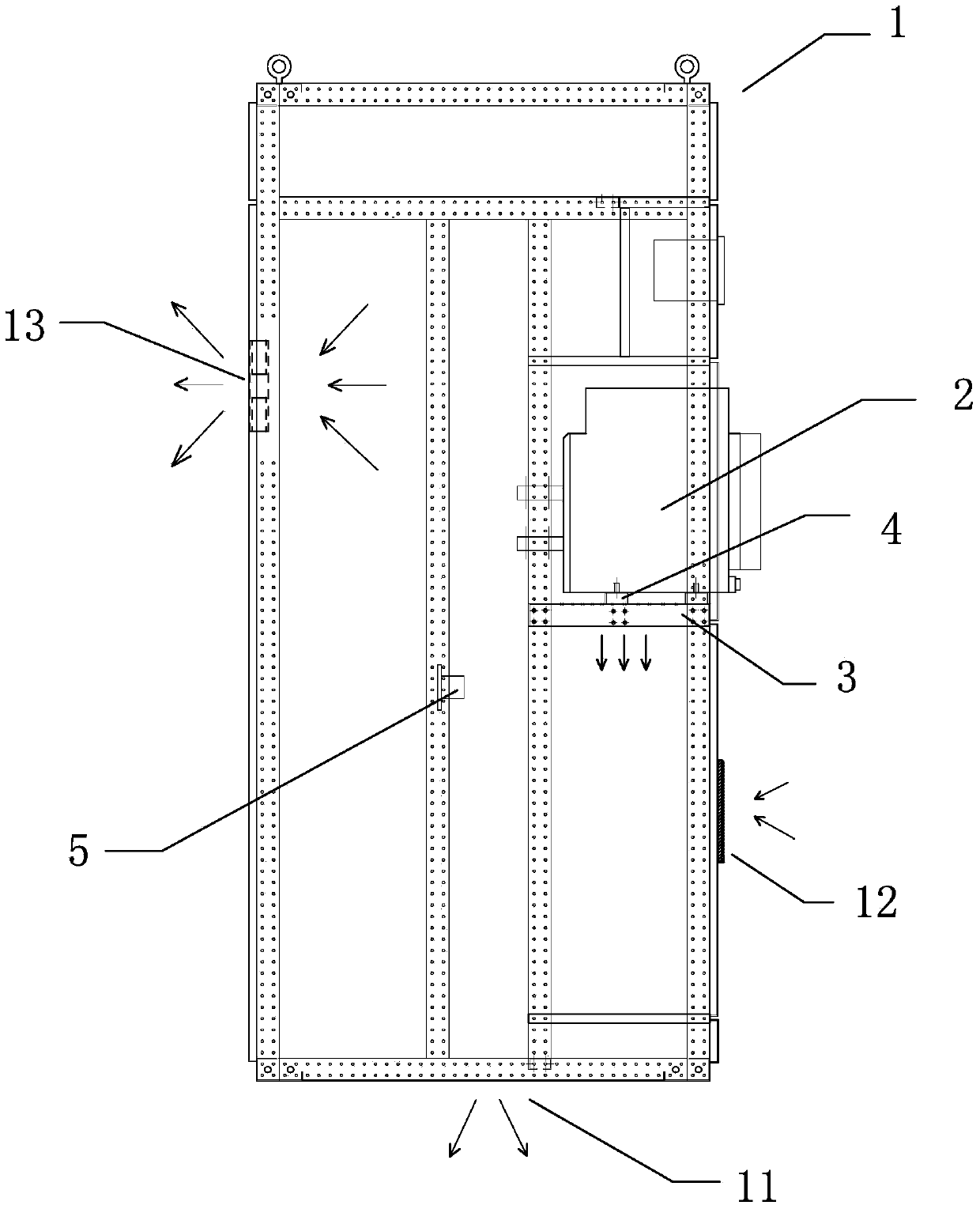

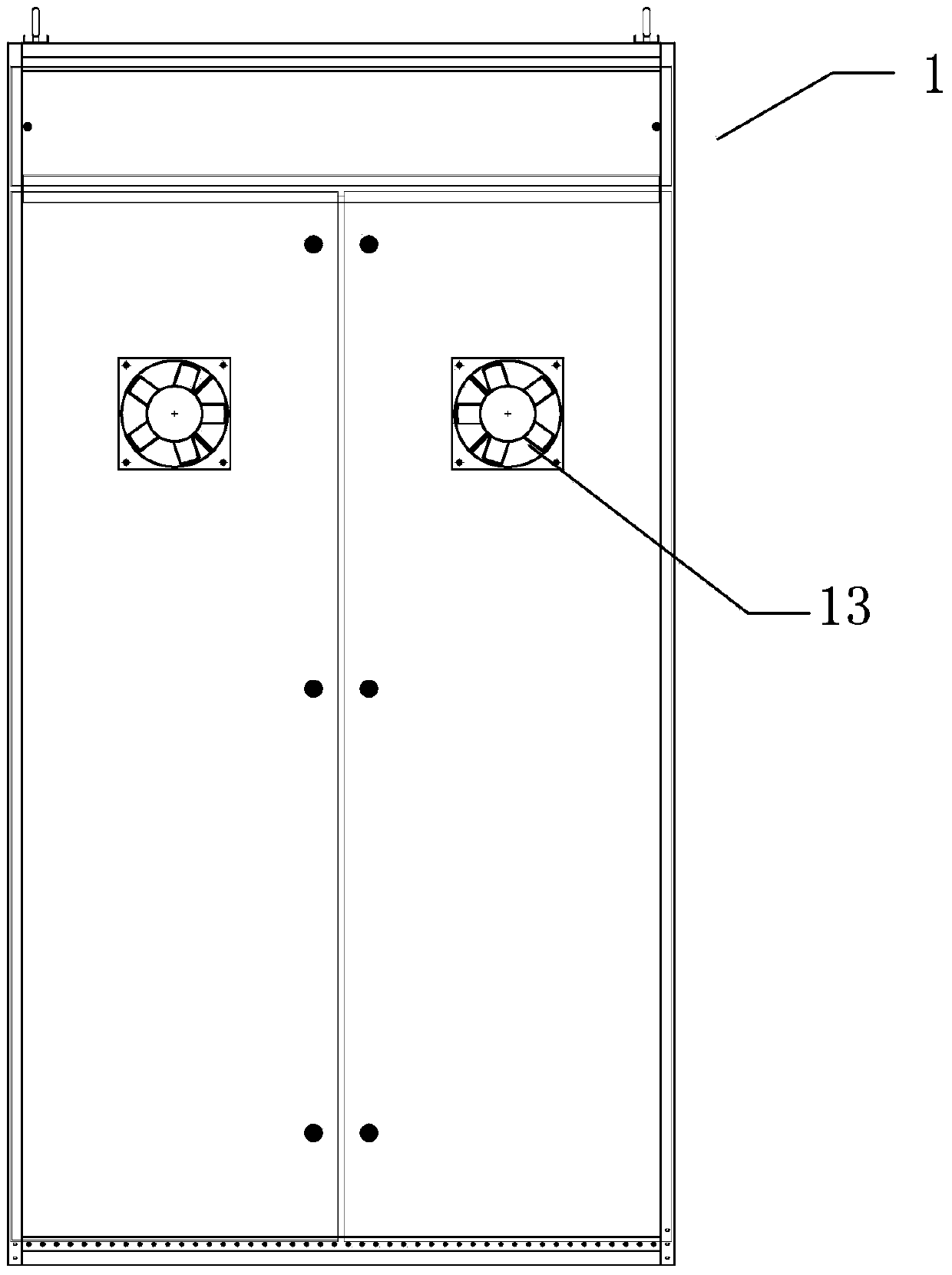

[0020] refer to Figure 1 to Figure 5 , Figure 1 to Figure 5 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, the ventilation system of the high-current circuit breaker equipment includes a large-current circuit breaker 2 and a cabinet 1 for installing the circuit breaker 2. The circuit breaker 2 It is installed and fixed in the cabinet body 1 through an installation base plate 3, and several pads 4 are arranged between the circuit breaker 2 and the installation base plate 3, and the circuit breaker 2 is raised by the pads 4 to reduce the overall force-bearing contact area , the installation bottom plate 3 is provided with a number of cooling slots, when the components are running, the heat generated by the components can be quickly conducted out of the cabinet body 1 through the cooling slots.

[0021] As shown in the figure, the cabinet body 1 is provided with a plurality of ventilation holes 11, air inlet hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com