External circulation bypass structure between converter transformer core pulling plate columns

A converter transformer and external technology, applied in the field of transformer manufacturing, can solve the problems of increased resistance loss, overheating, magnetic leakage and other problems of the pulling plate, and achieve the effect of reducing the pulling plate loss, reasonable layout and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

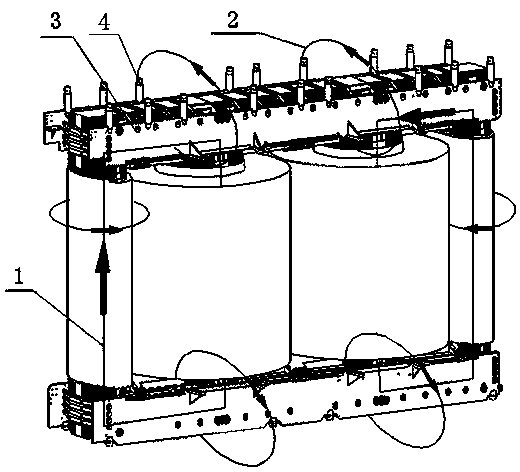

[0011] Refer to attached figure 1 , an external converter transformer core pull plate inter-column circulation bypass structure, a plurality of copper cables 4 are arranged in the wire clamp frame 3, the copper cables are connected to the coil outlets and then connected to the upper and lower clamps, the copper cables, the upper and lower clamps and the iron core The main column pull plate forms a short-circuit ring 2 along the iron core window.

[0012] Since the outlet current of the voltage regulating coil of the converter transformer can reach tens of thousands of amperes, in order to avoid the current passing through the side yoke pull plate with a small cross-section, the side yoke pull plate is disconnected from the upper and lower clamps, and an external copper cable is used instead to form a short circuit ring to prevent magnetic flux leakage from pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com