Non-contact type micro scale rotating motor based on ultrasonic radiation torque

A non-contact, ultrasonic radiation technology, which is applied in the program control and electrical program control of the sequence/logic controller, can solve the problems that the rotary motion cannot be directly realized, and achieve the effect of easy upgrade and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

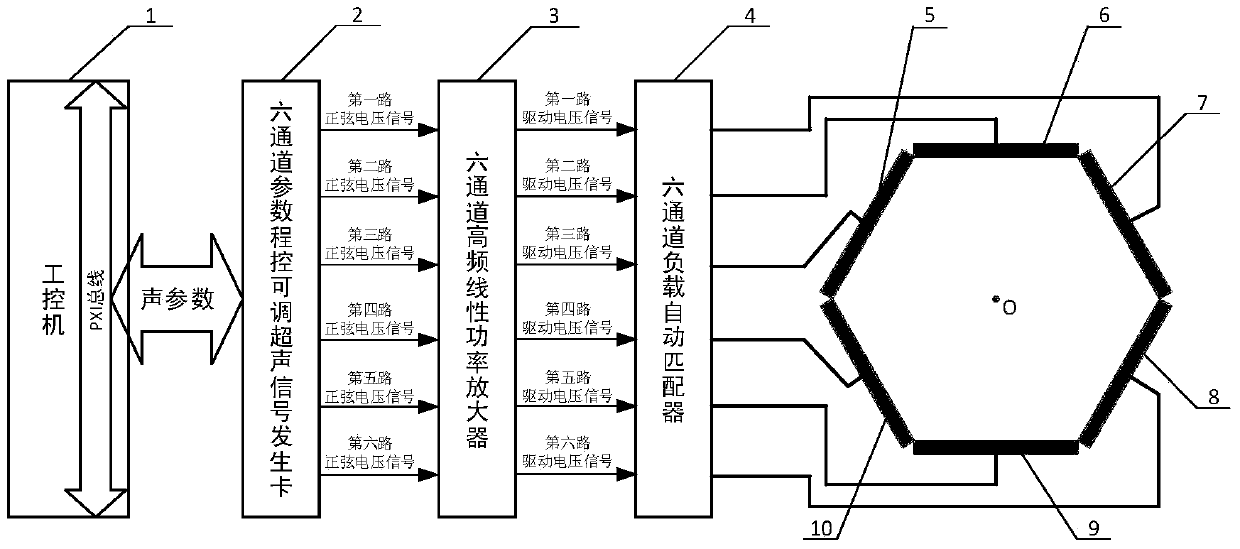

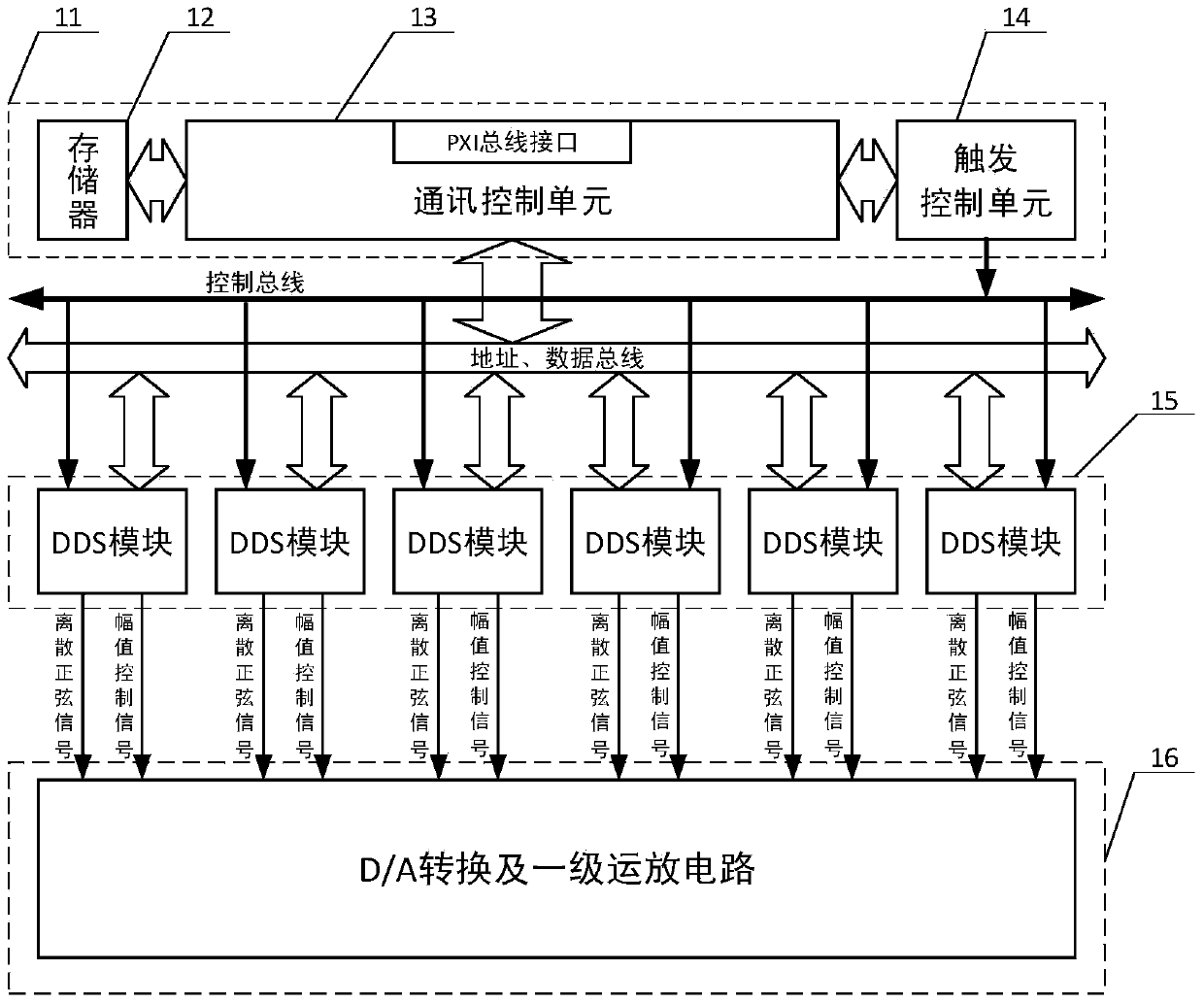

[0019] Such as figure 1 As shown, the non-contact micro-scale rotary motor system based on ultrasonic radiation torque of the present invention includes an industrial computer 1 with a PXI bus structure, a six-channel parameter program-controlled adjustable ultrasonic signal generation card 2, a six-channel high-frequency linear power amplifier 3, and a six-channel Automatic load matching device 4 and ultrasonic transducer groups 5, 6, 7, 8, 9, 10. The multi-channel parameter program-controlled adjustable ultrasonic signal generation card is installed in the PXI chassis, and according to the requirements of the rotation function, multiple sets of sinusoidal voltage signals with varying amplitudes are cyclically and sequentially generated. The sinusoidal voltage signal is amplified into a high-power sinusoidal drive voltage signal after being passed through a multi-channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com