Non-power wireless communication clamp AC ammeter

An AC ammeter and wireless communication technology, applied in the field of clamp AC ammeter, can solve problems such as power failure, achieve the effects of improving safety and reliability, facilitating on-site installation and use, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

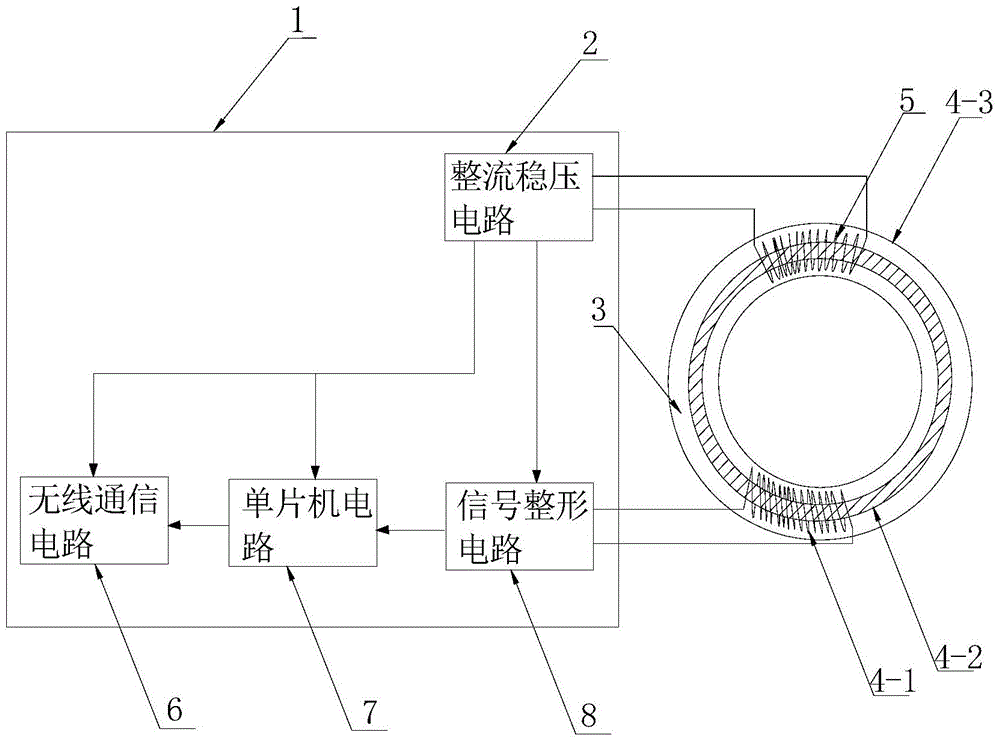

[0012] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the wireless communication clamp AC ammeter without power supply described in this embodiment, it comprises ammeter housing 1, rectification and voltage stabilization circuit 2, clamp current sensor 3, power supply coil 5, wireless communication circuit 6, single-chip microcomputer circuit 7 and Signal shaping circuit 8;

[0013] The clamp current sensor 3 includes a measuring coil 4-1, an iron core 4-2 and a sheath 4-3;

[0014] The rectifying and stabilizing circuit 2, the wireless communication circuit 6, the single-chip microcomputer circuit 7 and the signal shaping circuit 8 are all placed in the ammeter shell 1,

[0015] The measurement coil 4-1 and the power supply coil 5 are all wound on the iron core 4-2, and the measurement coil 4-1, the power supply coil 5 and the iron core 4-2 are all placed in the sheath 4-3;

[0016] The current signal output end of the power supply coil 5 is ...

specific Embodiment approach 2

[0019] Embodiment 2. This embodiment is a further description of the non-power wireless communication clamp AC ammeter described in Embodiment 1. The number of turns of the measuring coil 4 is 1000 turns.

specific Embodiment approach 3

[0020] Embodiment 3. This embodiment is a further description of the non-power wireless communication clamp AC ammeter described in Embodiment 1 or Embodiment 2. The number of turns of the power supply coil 5 is 200 turns.

[0021] The clamp AC ammeter without power supply wireless communication in the utility model adds an independent power supply coil inside the clamp sensor, and calculates the number of turns and wire diameter of the power supply coil required by the circuit based on the clamp ammeter. The electric energy obtained by the power supply coil is converted into a DC power supply suitable for the normal operation of the ammeter measuring circuit through the rectifying and stabilizing circuit. The signal shaping circuit converts the signal induced by the measuring coil into a voltage signal that can be collected by the single-chip microcomputer. The signal is converted into a digital signal by the analog-to-digital converter on the single-chip microcomputer circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com