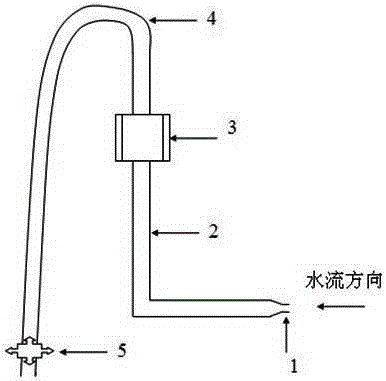

A kind of sediment solution sampling device and sampling method

A sampling device and solution technology, applied to the sampling device and other directions, can solve the problems such as the size and shape of the sampler are not optimized, the sampling method is unreasonable, and the water flow interference, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

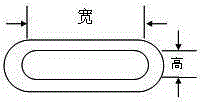

Method used

Image

Examples

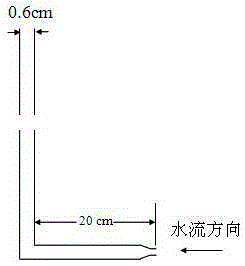

Embodiment 1

[0027] The sediment concentration is measured in the laboratory glass tank, the tank is 12m long, 0.42m wide, and 0.7m high, and a constant and uniform sand-carrying water flow with a water depth of 18cm and a stable concentration is formed in the tank. The concentration of sediment in the direction of water depth is different. When the turbulent characteristics of water flow are different, the distribution pattern of sediment concentration will be different. When the water flow is a turbulent flow in an ordinary open channel with a smooth bed surface (the distribution law of the average flow velocity of the water flow is as follows Figure 4 shown), the sediment concentration measurement results are as follows Figure 5 shown. It can be seen that the sediment concentration is in the reverse S-shaped distribution form in the vertical direction, which is consistent with the theoretical distribution form. The distribution of the sediment concentration can be calculated by using...

Embodiment 2

[0029] To change the water flow conditions and the average concentration of sediment in the laboratory tank, the specific method can be to arrange rigid cylinders with strong water resistance on the bed surface, increase the roughness of the tank bed surface, and form a stable water depth of 18cm in the tank. Concentrated sand-carrying water flow. Similarly, the concentration of sediment in the direction of water depth is different, and the measurement results of sediment concentration are as follows: Figure 6 As shown, it can be seen that the sediment concentration is in a hyperbolic upward concave distribution form in the vertical direction, which is caused by the large roughness of the bed surface and the difference in the turbulent characteristics of the water flow in the tank from the smooth side wall. In this case, the traditional The rouse formula of the sediment concentration distribution cannot be calculated, and other suitable methods need to be sought. By comparin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com