Gangue-filling coal mining method for sharp inclined coal seam under flexible shield support

A steeply inclined, flexible shielding support technology, applied in the fields of backfill, underground mining, surface mining, etc., can solve the problems of large backfill system, collapse of mining area, and high pre-investment, to simplify the backfill process, reduce the workload of frame adjustment, The effect of large filling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention provides a coal mining method in which steeply inclined coal seam softly covers and supports descending gangue filling. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

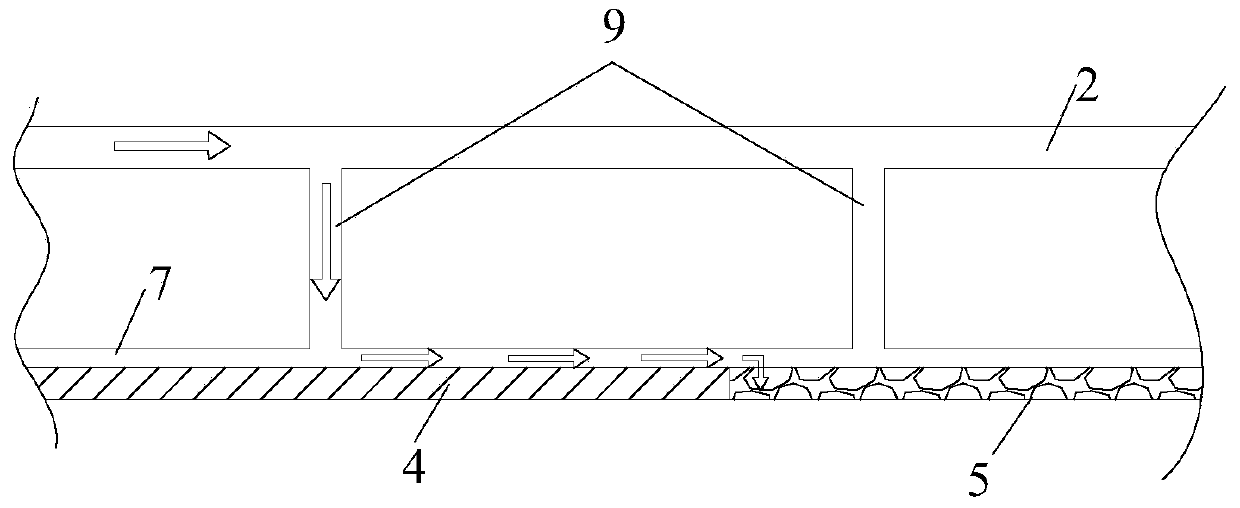

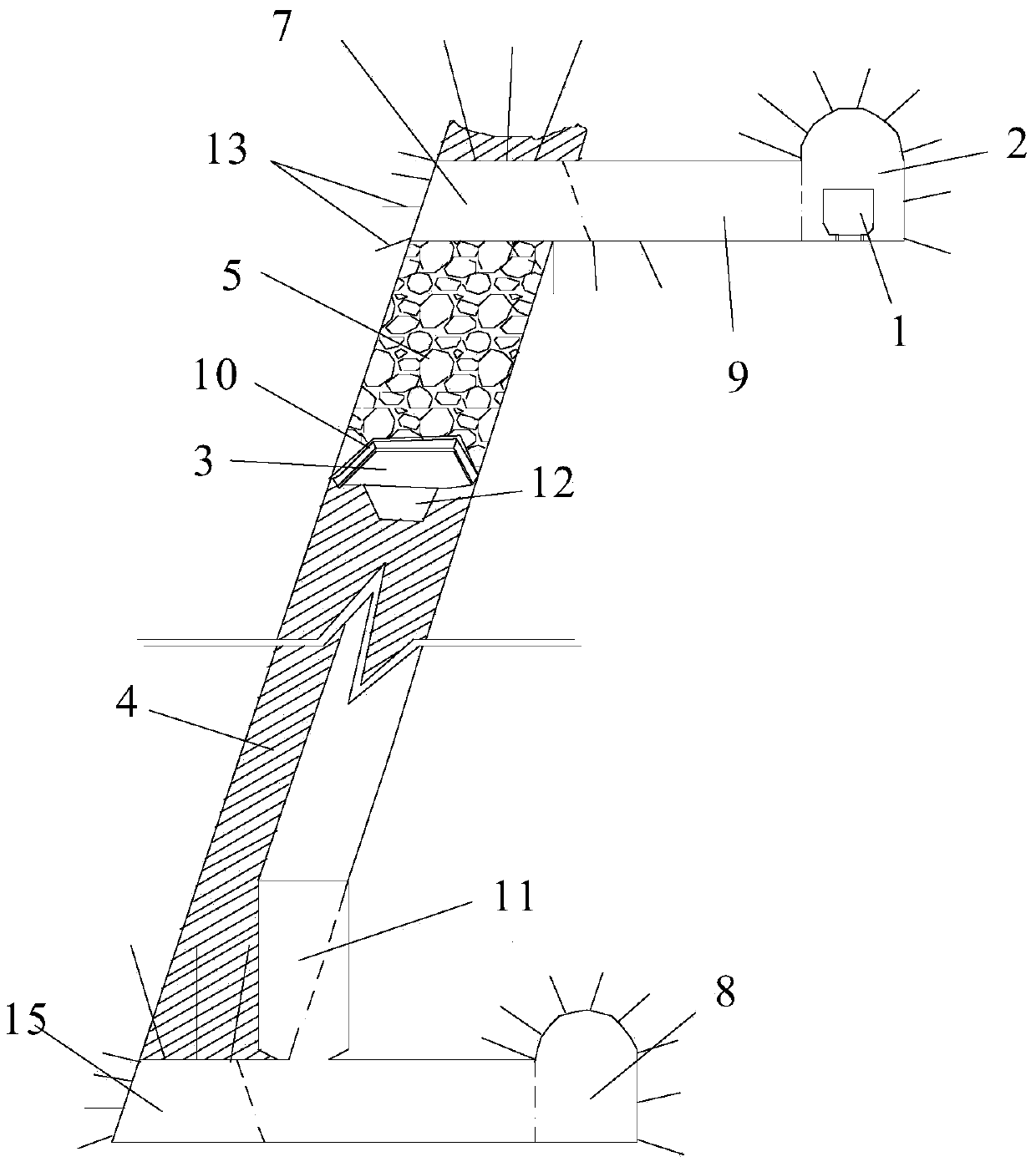

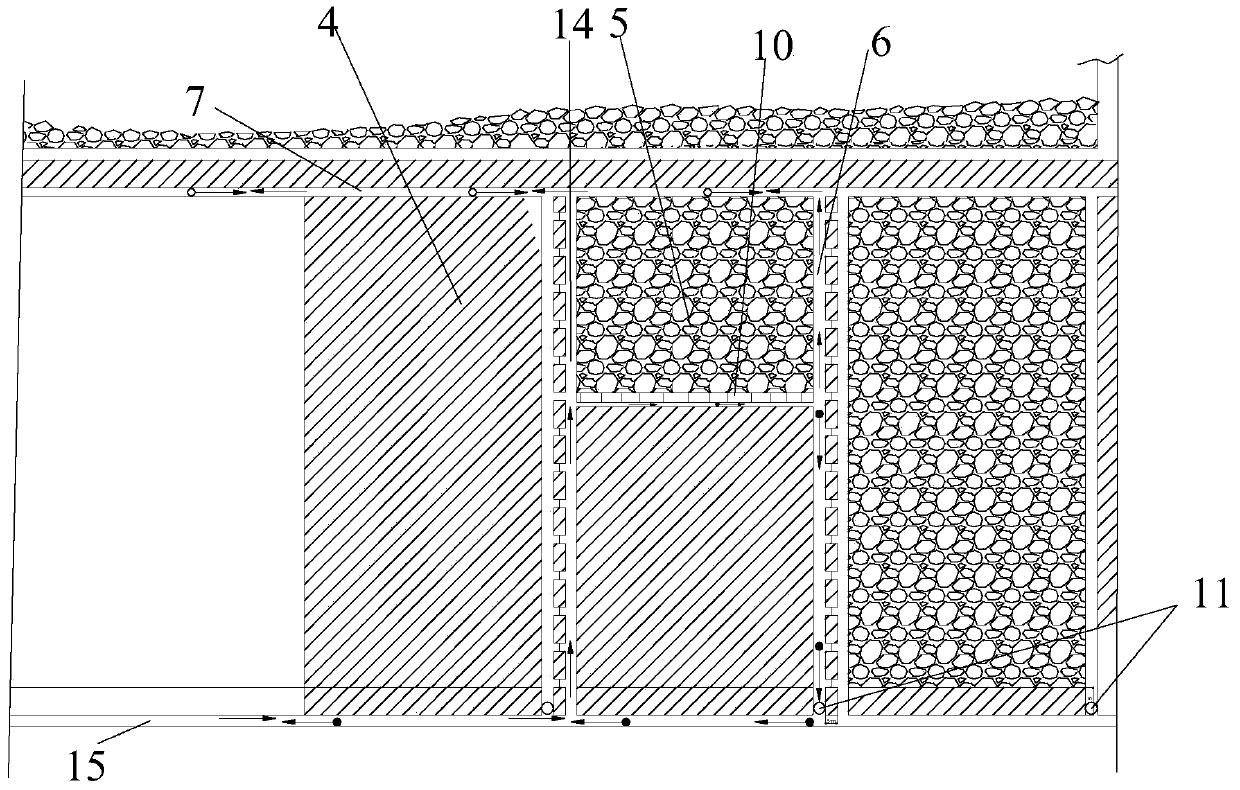

[0019] The present invention provides a kind of coal mining method of softly covering and supporting descending gangue filling in the steeply inclined coal seam, such as figure 1 , figure 2 and image 3 As shown, it includes the following steps:

[0020] Step 1: divide the coal seam into several sub-zones along the inclination direction of the coal seam, and the sub-zone width is generally 40-80m;

[0021] Step 2: Excavate the floor road 2 on the coal seam floor of each sub-zone, which is used for the mine ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com