A combined foam concrete formwork

A foamed concrete, combined technology, applied in the field preparation of formwork/formwork components and building components, construction, etc., can solve the problem of inability to solve the problem of slurry leakage of non-aggregate foamed concrete, and achieve convenient and fast connection and installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

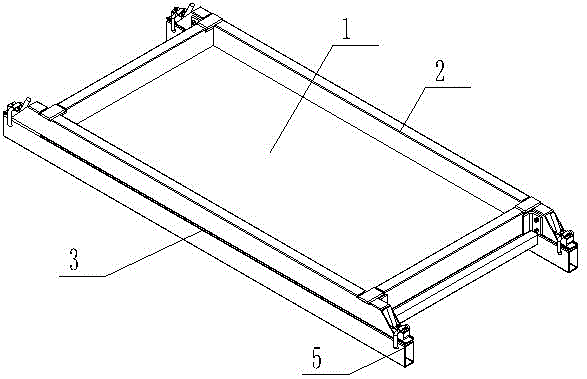

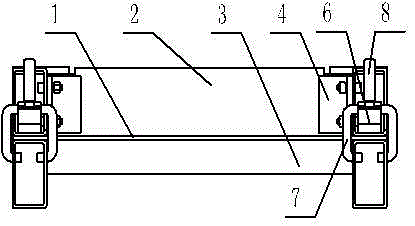

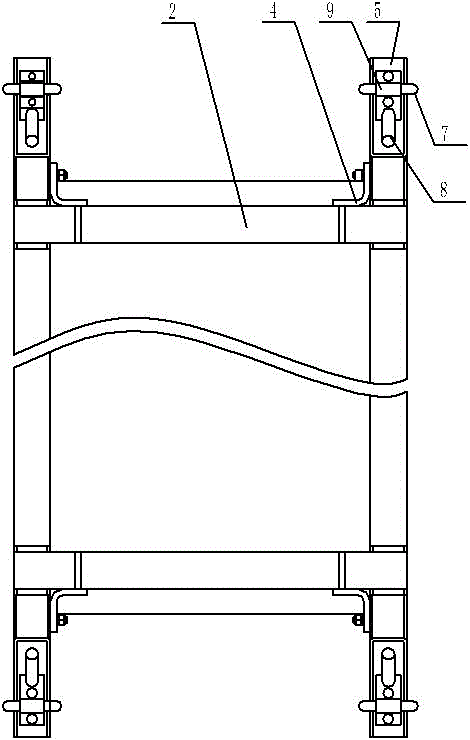

[0019] refer to figure 1 , Fig. 2 and Fig. 3, the present invention comprises a bottom plate 1, a frame 2 and a bottom frame 3, the bottom plate 1 is placed on the bottom frame 3, the frame 2 is placed on the bottom plate 1, the four sides of the frame 2 The L-shaped limiting block 4 is connected and fixed, and the two sides of the L-shaped limiting block 4 are respectively fixed to the adjacent two sides of the frame 2 . The two opposite sides of the bottom frame 3 and the frame 2 both extend outward, and the extension ends 5 are fastened and connected by a pressing device. The compression device includes a compression block 6 and a stirrup 7, the stirrup 7 is a "mouth"-shaped structure with one end open, the two ends of the opening end are bent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com