A kind of production method of reclaimed rubber

A production method and technology for reclaimed rubber, applied in the direction of plastic recycling, recycling technology, etc., can solve problems such as waste of raw materials, and achieve the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

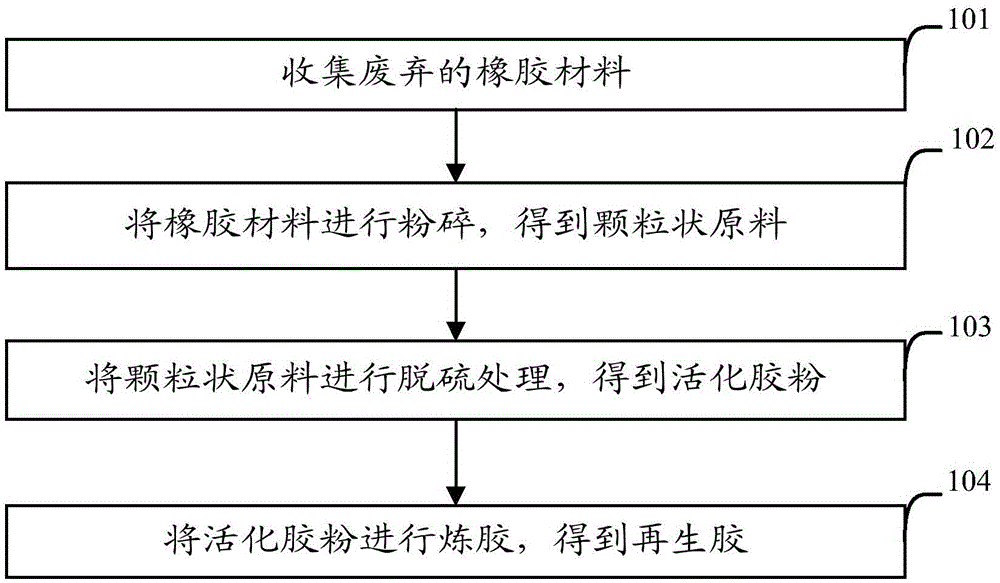

[0016] Please refer to figure 1 , provides a kind of production method of reclaimed rubber in the embodiment of the present invention, comprises the following steps:

[0017] Step 101: collecting waste rubber materials;

[0018] In step 101, it is the raw material preparation stage of the whole production method. In this step, the waste rubber materials produced in the industrial production process are collected and sorted, and can be sorted according to different types of rubber materials, and then different types of rubber The materials are then processed separately.

[0019] Step 102: crushing the rubber material to obtain granular raw materials;

[0020] After the waste rubber material is collected, it needs to be pulverized to obtain granular raw materials, which is convenient for subsequent desulfurization operations.

[0021] Step 103: Desulfurize the granular raw material to obtain activated rubber powder;

[0022] After the granular raw materials are obtained, the...

Embodiment 2

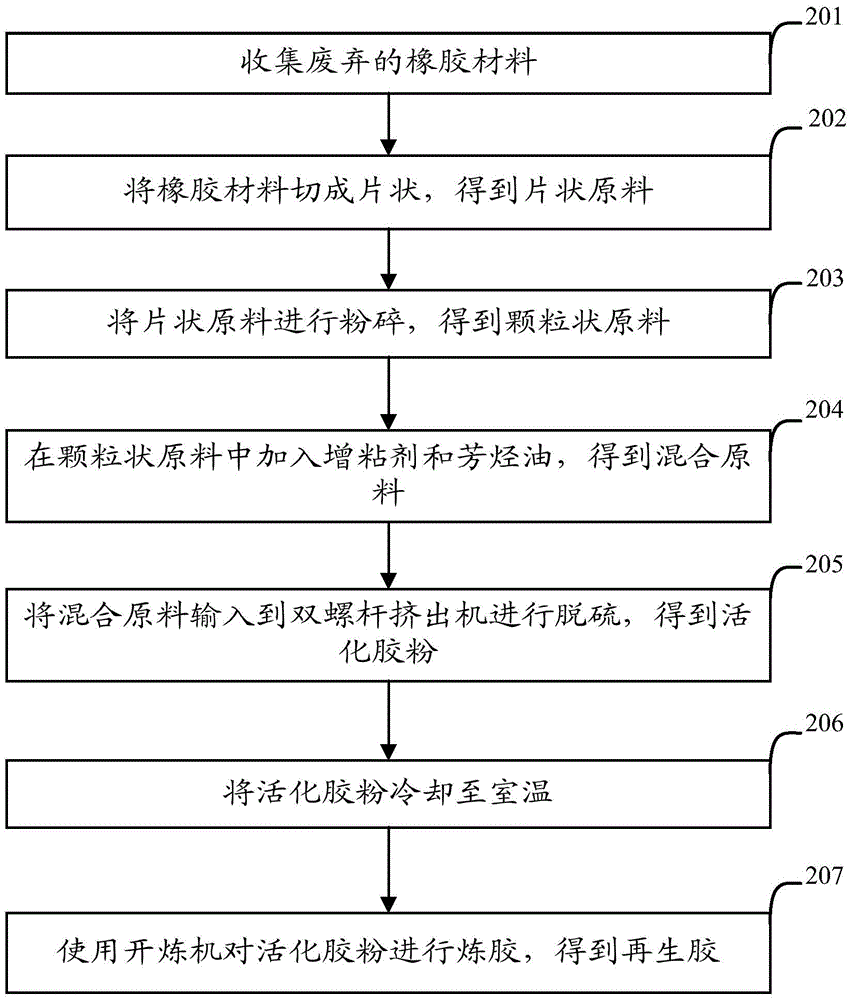

[0028] Please refer to figure 2 , the production method of the reclaimed rubber that the embodiment of the present invention provides comprises the following steps:

[0029] Step 201: collecting waste rubber materials;

[0030] In step 201, the collected waste rubber materials are mainly waste tires, for example, waste car tires or bicycle tires. Alternatively, it may be a waste capsule.

[0031] Step 202: cutting the rubber material into flakes to obtain flake raw materials;

[0032] In the process of counting the rubber material, it is first cut into flakes through the operation of step 202 to obtain flake raw materials; in this way, the flake raw materials are easy to be crushed during pulverization.

[0033] Step 203: crushing the flake raw materials to obtain granular raw materials;

[0034] In step 203, the flaky raw material is pulverized to obtain granular raw material. When the flaky raw material is crushed, it is easy to be pulverized, and it is easy to obtain g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com