Collecting type 90-degree steel wire cord fabric cutting machine and control method thereof

A steel cord and cutting machine technology, applied in the field of rubber tire machinery, can solve the problems of affecting the efficiency of the whole machine, the small space for cutting speed improvement, and the slow speed of the splicing device, so as to simplify the servo system and control system, simplify the overall control steps, The effect of improving the overall control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0049] It should be noted that the conveying direction of the material in the present invention will change. In the text, including the front and back mentioned in the claims, the front and rear are set by the actual material conveying direction, and the left and right are set in the direction perpendicular to the material conveying direction. .

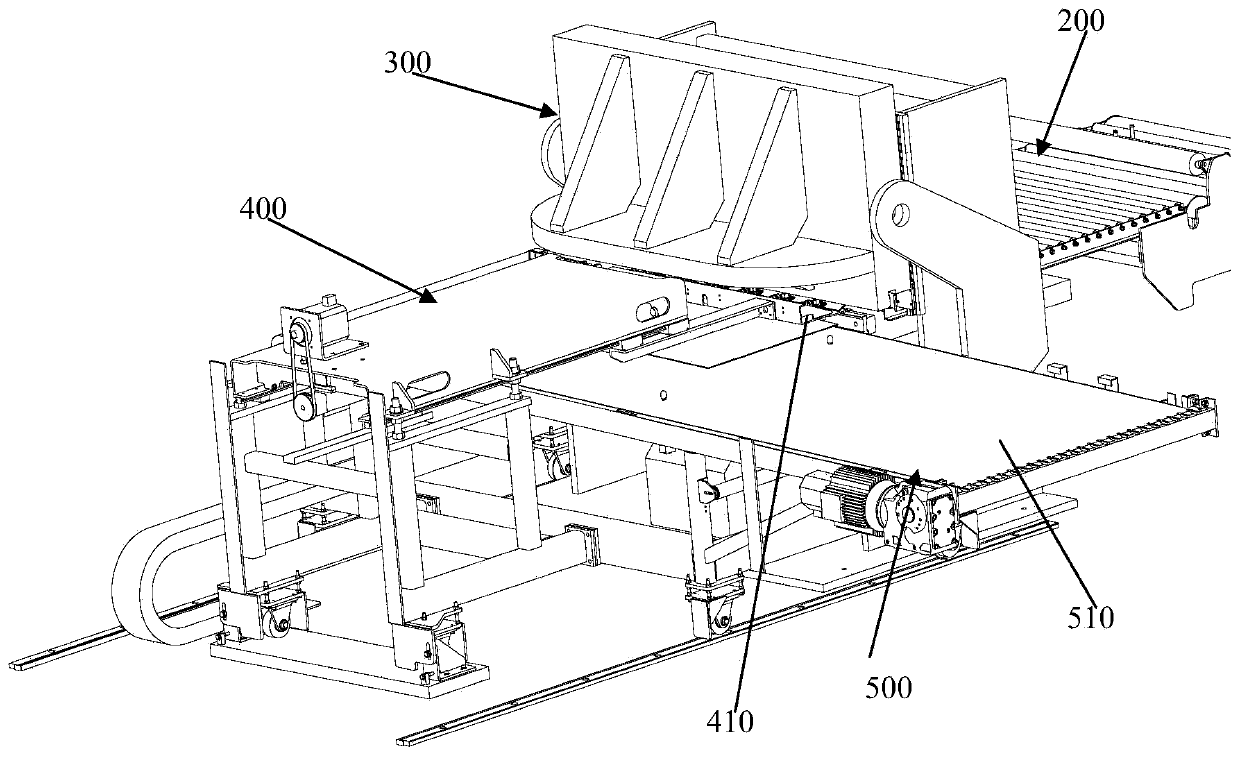

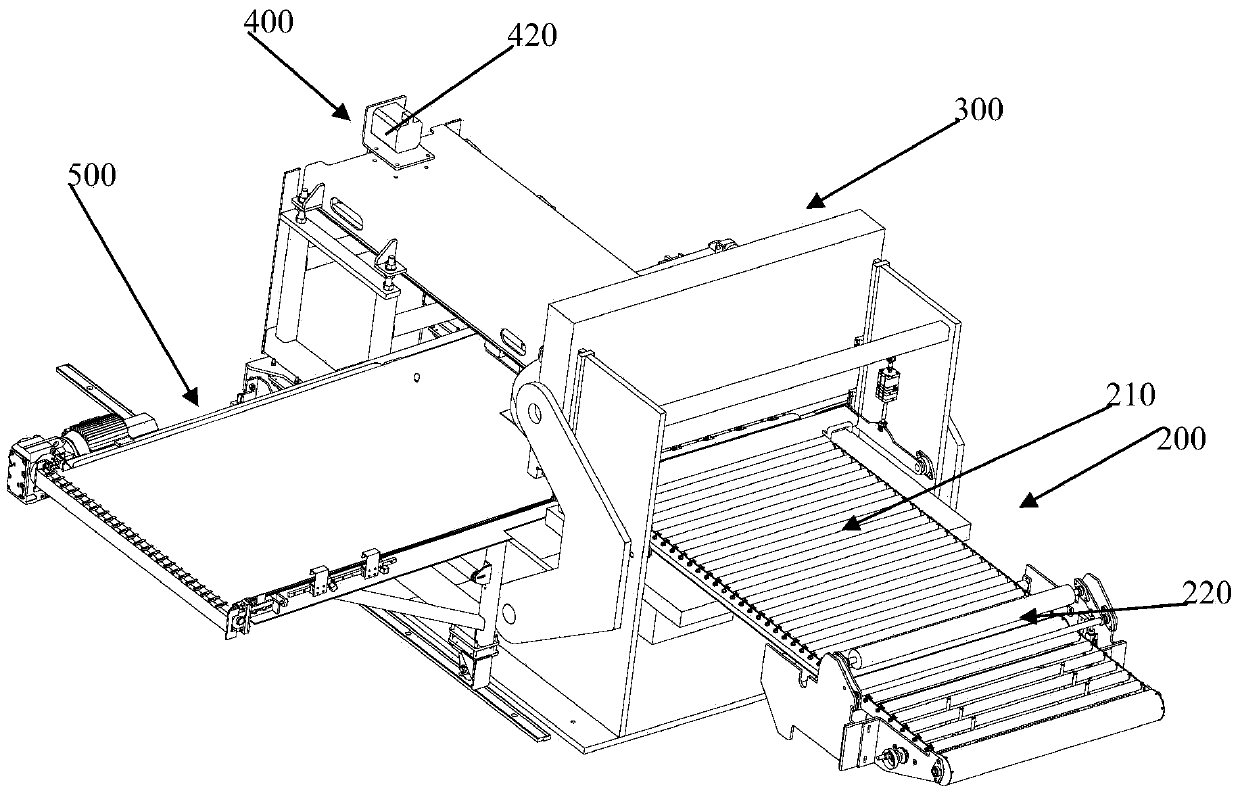

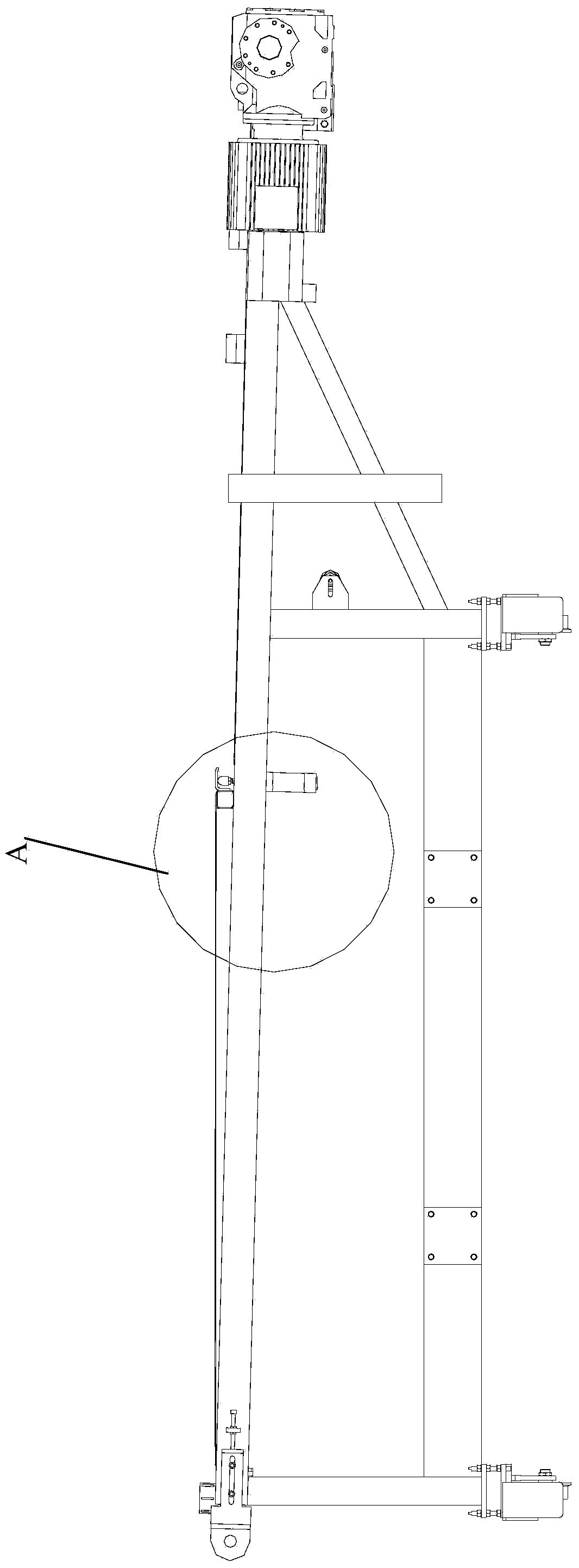

[0050] Such as Figure 1-17As shown, the present invention discloses an access-type 90° steel cord cutting machine, which constitutes an L-shaped layout as a whole, which includes a guiding device 100, an input device 200, a shearing device 300, a cloth pulling device 400, and a cloth connecting device 500, a splicing device, an output dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com