Screw driver

A screwdriver and cutter head technology, applied in screwdrivers, wrenches, wrenches, etc., can solve the problems of failure to remove dust and absorb screws, easy accumulation of dust on the surface of screws, small contact area between hands and handles, etc., to increase dust removal and Absorption effect, increased resistance, and convenient hand pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

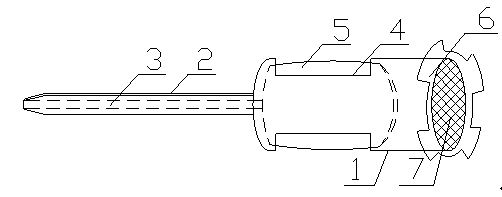

[0015] Such as figure 1 As shown, the present invention provides a screwdriver, including a handle 1 and a cutter head 2 fixed on one end of the handle 1, and also includes an air bag 5 and a tube body 3, wherein the air bag 5 is fixed in the handle 1, and the The tube body 3 is fixed in the cutter head 2, and an air hole is provided on the cutter head 2 tip; the air outlet of the air bag 5 is connected to one end of the tube body 3, and the other end of the tube body 3 extends to the air hole; The surface of the handle 1 is provided with an opening 4 for pressing the air bag 5, and the air bag 5 is sucked or exhausted by pressing, so as to realize suction or dust removal at the tip of the cutter head 2.

[0016] In order to increase the contact area between the hand and the airbag, two openings 4 are symmetrically arranged on the handle. As shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com