Continuous sectional-type dead-pig-carbonizing processing device and technology

A processing device and a segmented technology, which is applied in the field of continuous segmented carbonization of dead pigs, can solve problems such as the inability to apply carbonization of dead pigs, and achieve the effects of avoiding secondary pollution and reducing the production of dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

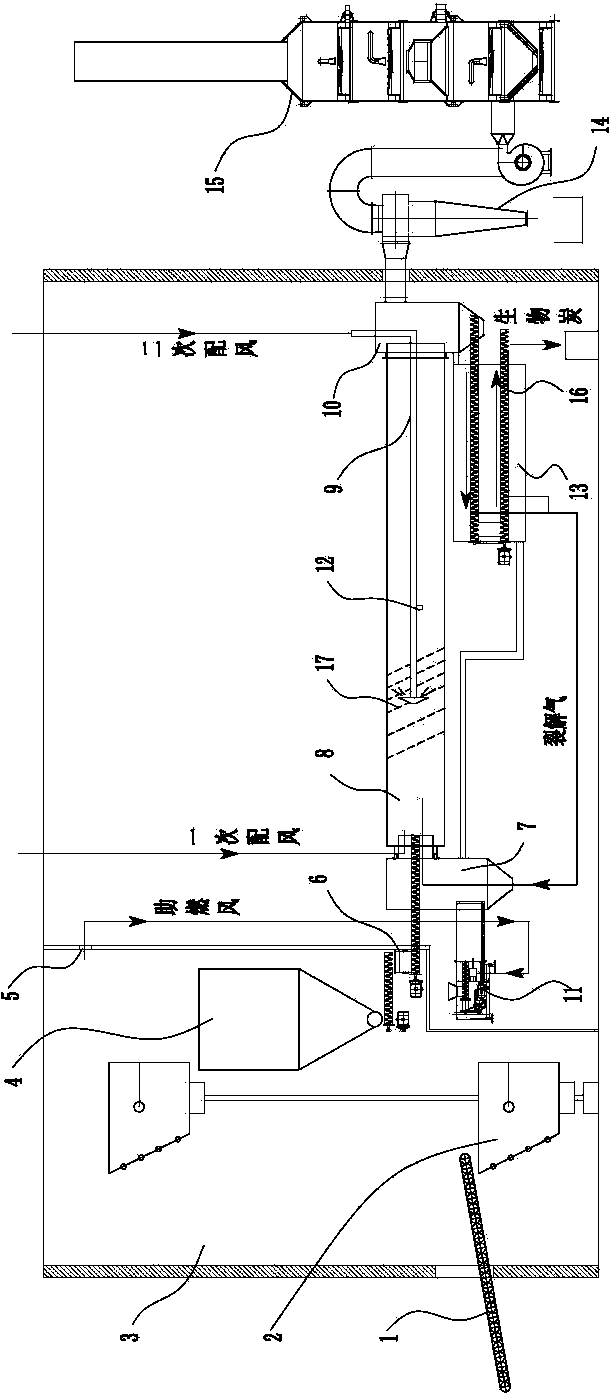

[0029] Embodiment: a kind of continuous segmented dead pig carbonization treatment device and process, such as figure 1 shown. The left end of the device is the starting end, and sick and dead pigs enter the isolation chamber 3 through the conveyor belt 1 . In the isolation room 3, the sick and dead pigs are lifted to the feed port of the primary shredder 4 through the bucket elevator 2. The first-level shredder 6 is chopped into fritters, and the first-level shredder can also directly align the discharge port with the second-level shredder inlet, and adopt the opening and closing of the hopper on the lower side of the first-level shredder to control the conveying capacity. One side of the isolation chamber 3 near the drum is provided with a vent, and the vent is provided with a ventilation duct connected to the air inlet of the combustion furnace, and an induced draft fan providing airflow power is provided on the ventilation duct to replace the air in the isolation room.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com