Electrode plate automatic cleaning machine

An electrode plate, automatic technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as low work efficiency, endangering life and health, affecting electroplating efficiency, etc., to achieve easy replacement and personal safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

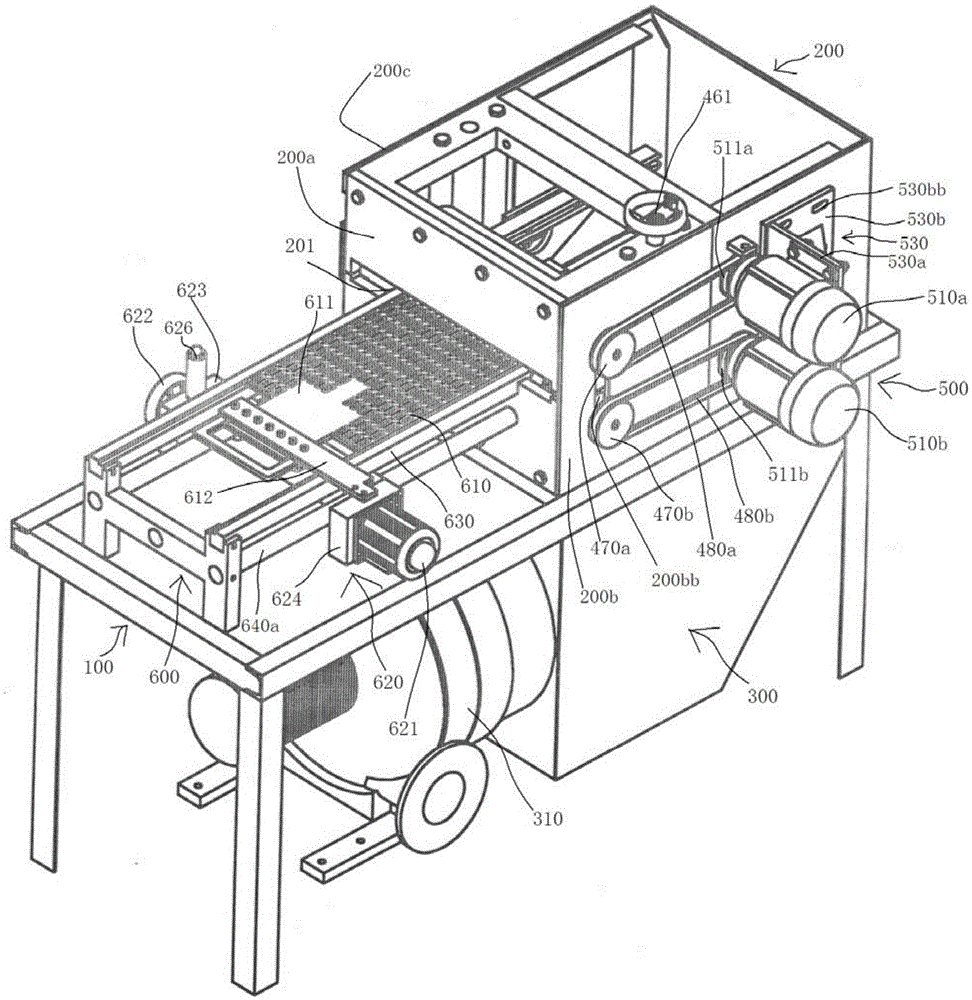

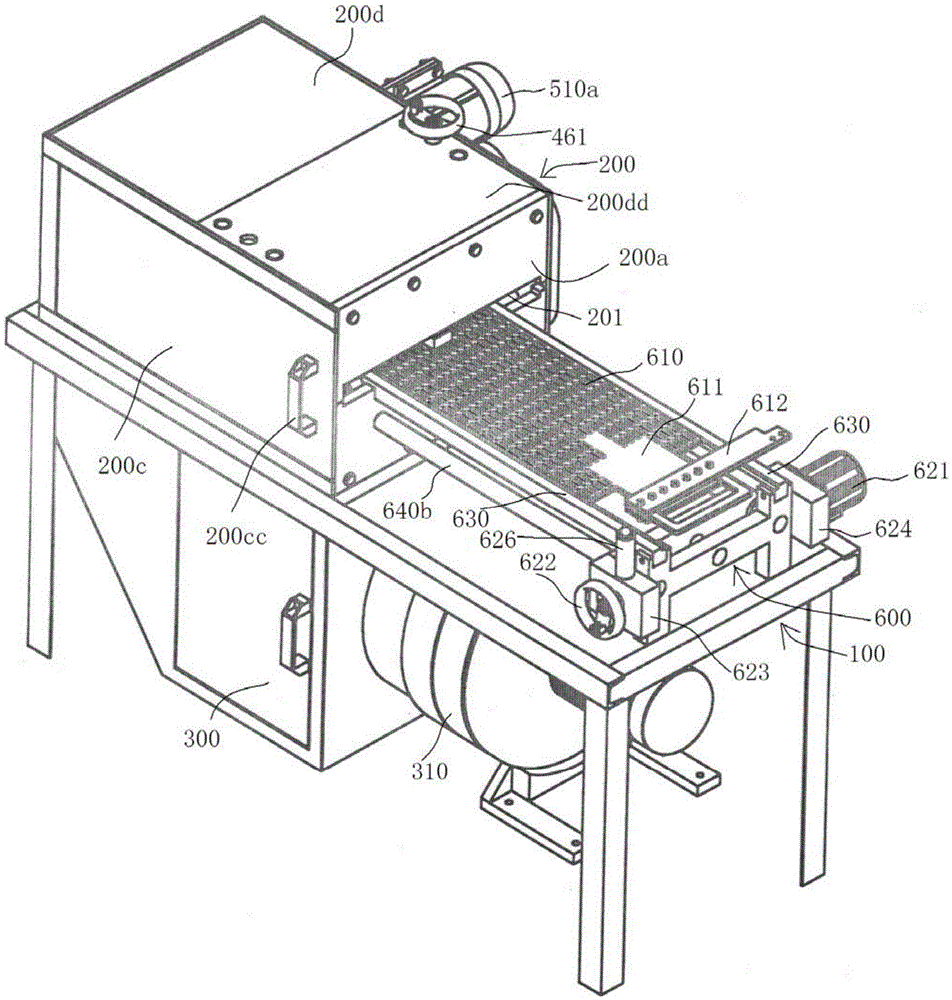

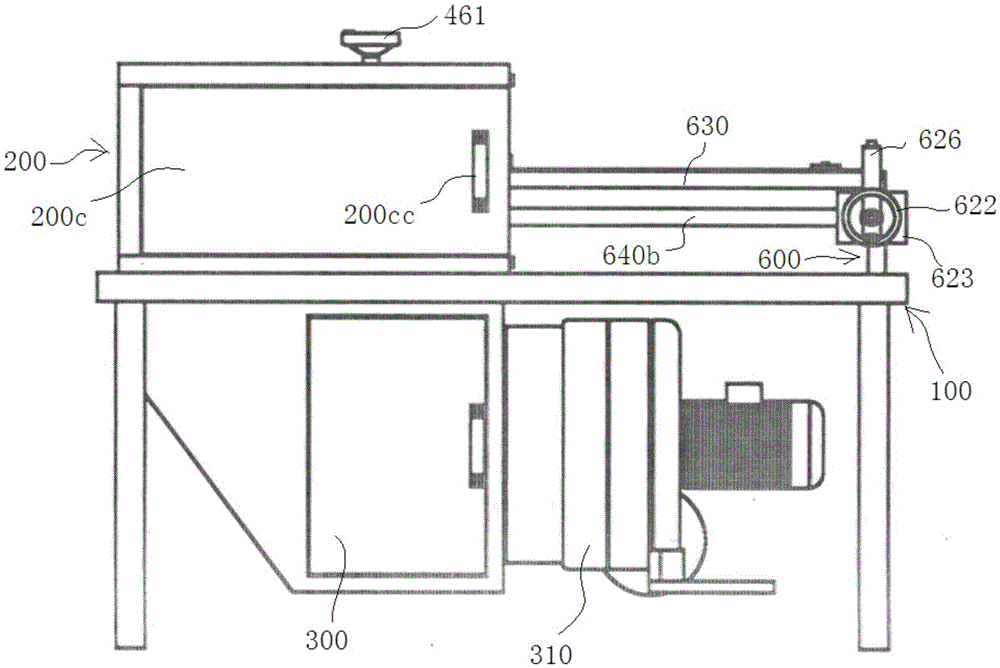

[0037] see Figure 1 to Figure 7As shown, the electrode plate automatic impurity removal machine includes a frame 100, and an impurity removal chamber 200 is arranged on the upper end of the tail end of the frame 100, and a dust recovery chamber 300 is arranged on the lower part of the tail end of the frame 100, and the dust recovery chamber 300 is connected with the impurity removal chamber. The room 200 is connected, and the dust recovery room 300 is also connected with an exhaust fan 310. The impurity removal room 200 will generate dust during the working process, and the exhaust fan 310 will form a negative pressure in the dust recovery room 300, and the dust will be absorbed into the dust recovery room. Within 300, it is guaranteed tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com