Power generating apparatus using flowing water

A technology for generating devices and power, which is applied in the field of power generating devices using flowing water, can solve the problems of not being able to improve the rotational power, and achieve the effect of improving efficiency and reducing the range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, a detailed description will be given with reference to preferred embodiments of the present invention.

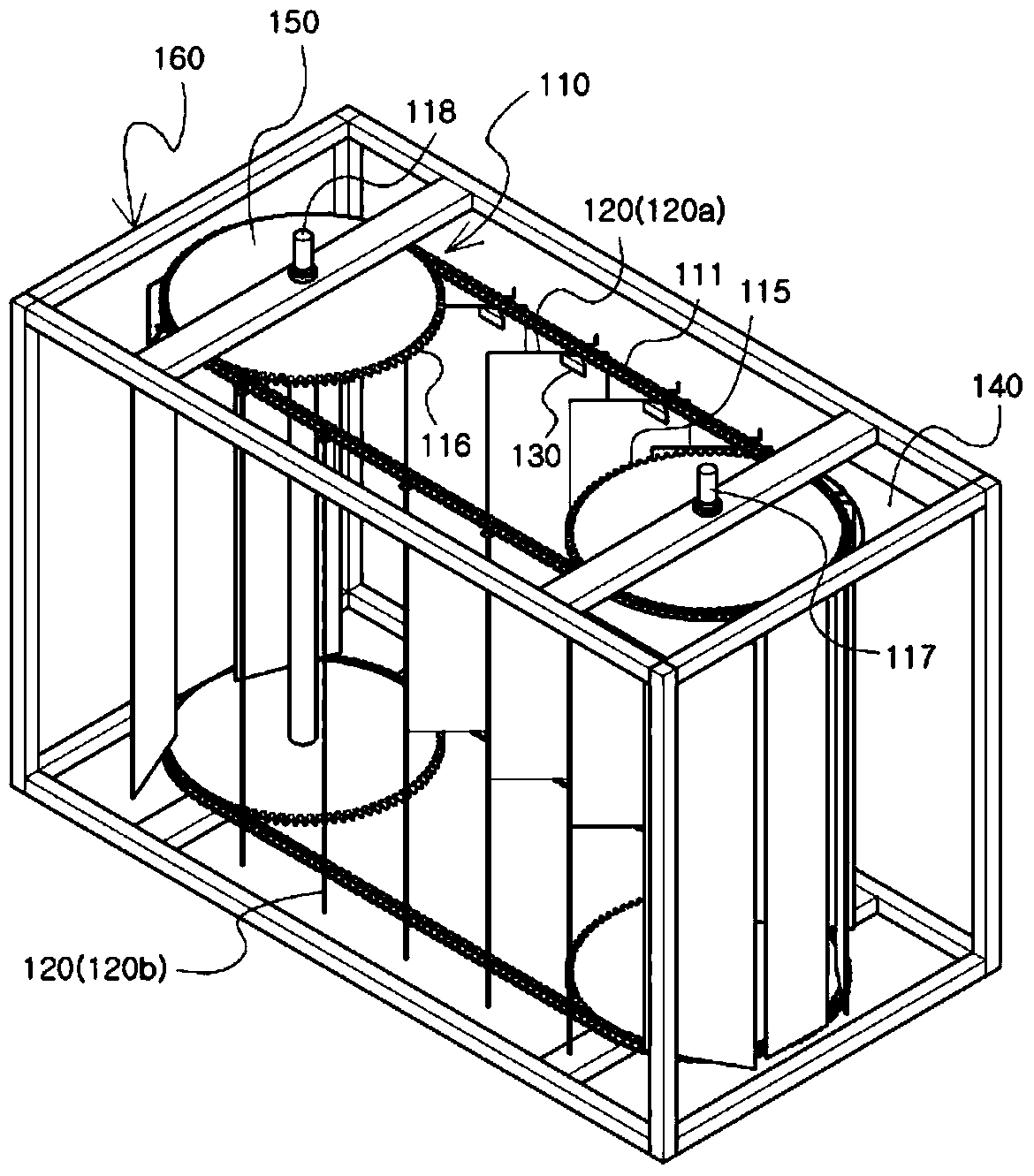

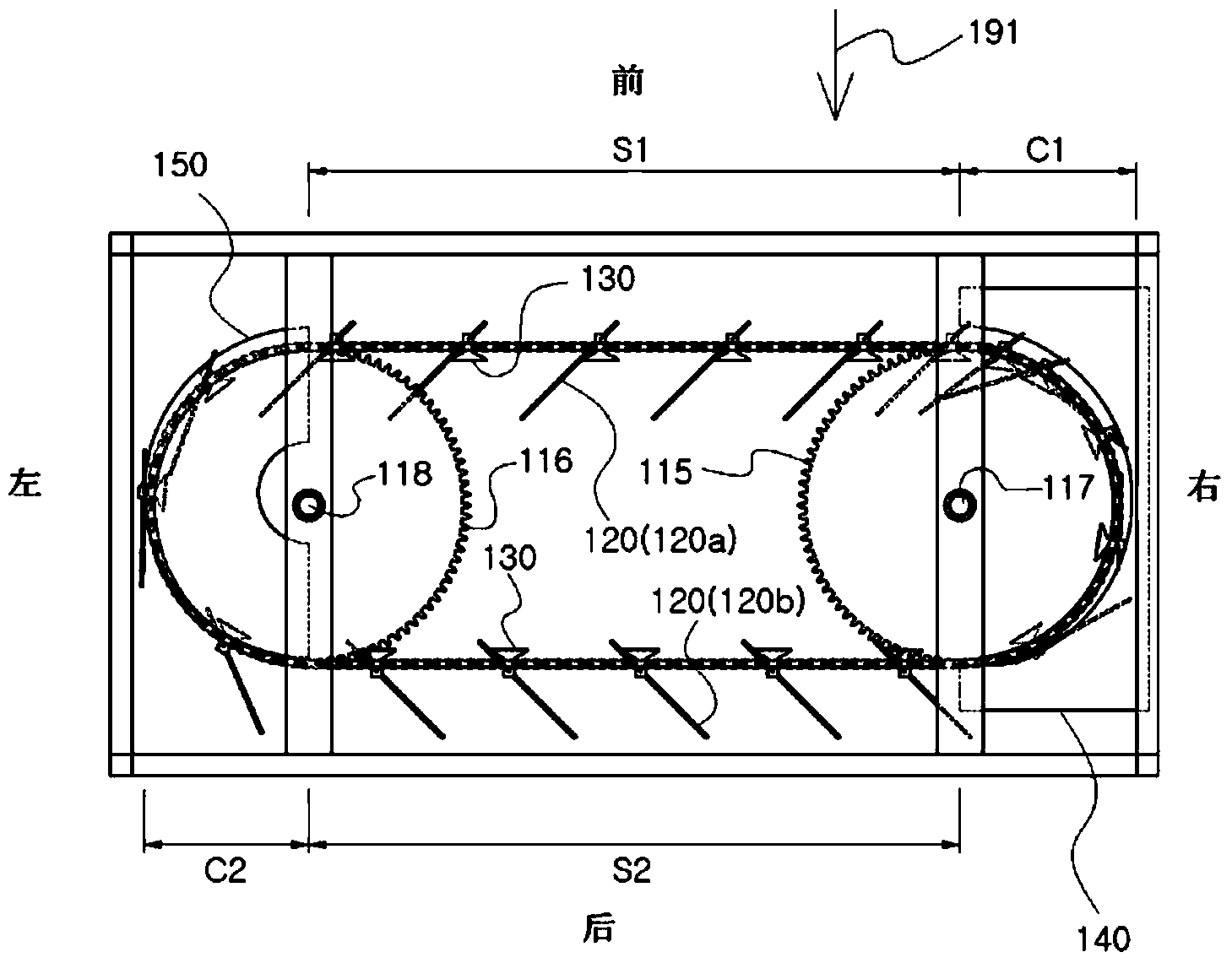

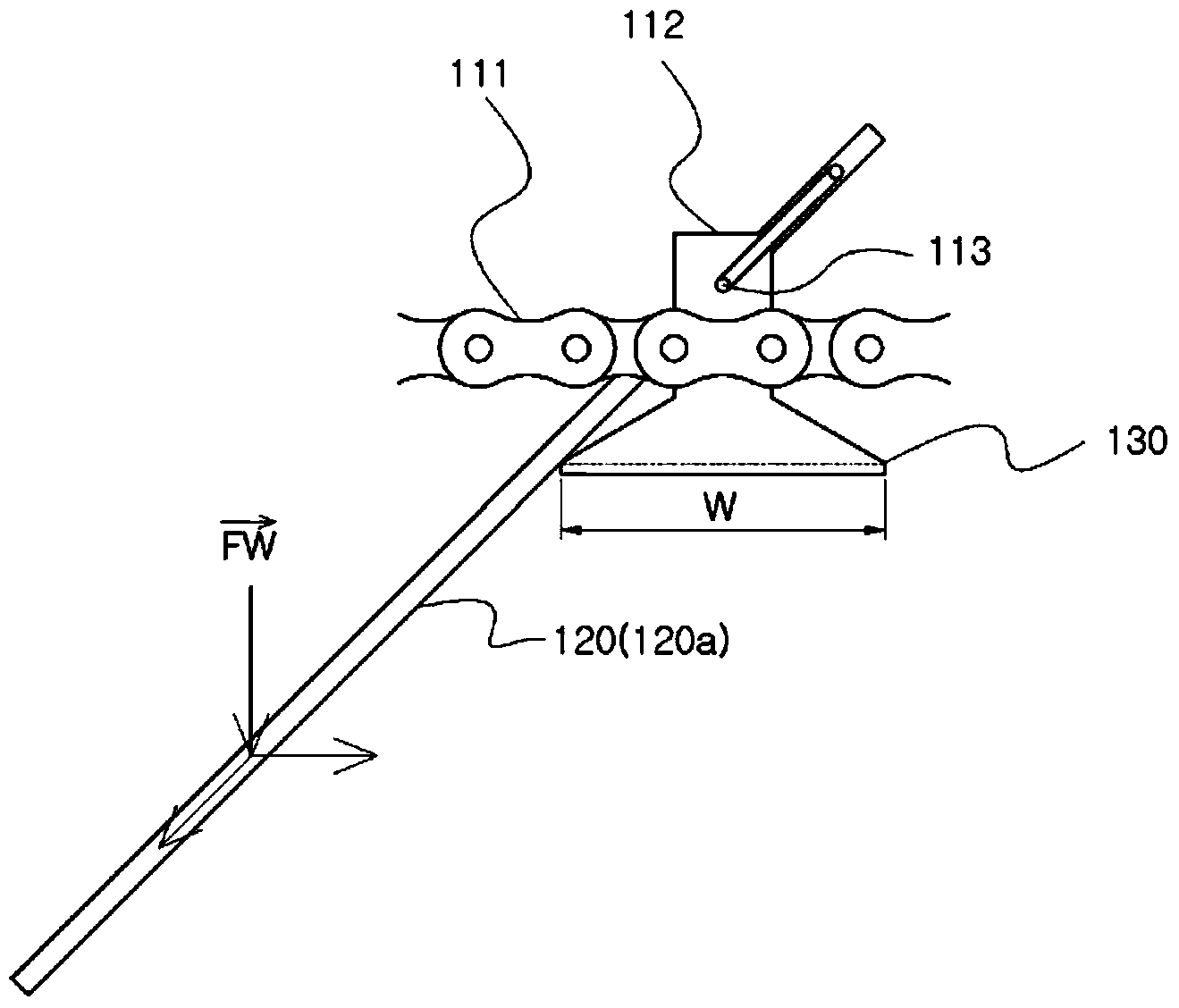

[0026] Such as figure 1 as well as figure 2 As shown, according to the power generation device using flowing water according to the first embodiment of the present invention, the chain of the chain circulation device 110 is provided with a plurality of blades 120 at predetermined intervals, and the chain circulation device 110 is formed with a first chain for the chain 111 to move linearly. A straight line section S1 and a second straight line section S2, when the blade 120 installed on the chain circulation device 110 is immersed in water, the water passes through the blade 120a of the first straight line section S1 and then passes through the blade 120b of the second straight line section S2 , the blade 120 is locked to the stopper 130 of the chain 111, and the blade 120a of the first straight line section S1 and the blade 120b of the second straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com